Infusing liquids into polymers makes long lasting, self–replenishing material that repels deadly bacterial build-up

More than 80 percent of microbial infections in the human body are caused by a build–up of bacteria, according to the National Institutes of Health. Bacteria cells gain a foothold in the body by accumulating and forming into adhesive colonies called biofilms, which help them to thrive and survive but cause infections and associated life–threatening risks to their human hosts. These biofilms commonly form on medical surfaces including those of mechanical heart valves, urinary catheters, intravenous catheters, and implants. But a new study reported in the inaugural issue of ACS Biomaterials Science and Engineering demonstrates a powerful, long–lasting repellent surface technology that can be used with medical materials to prevent infections caused by biofilms.

The new approach, which its inventors are calling “liquid–infused polymers”, joins an arsenal of slippery surface coatings that have been developed at Harvard’s Wyss Institute for Biologically Inspired Engineering and School of Engineering and Applied Sciences (SEAS).

The technology leverages the molecular structure of polymers, which makes them highly capable of taking up and storing considerable volumes of lubricating liquids in their molecular structure, like sponges. This allows for absorption of a large reservoir of lubricant, which can then travel to the surface and render it continuously slippery and repellent — creating an environment that challenges bacteria’s ability to colonize. The team led by Joanna Aizenberg — Wyss Institute Core Faculty member, the Amy Smith Berylson Professor of Materials Science at Harvard SEAS, Professor of Chemistry and Chemical Biology in Harvard’s Faculty of Arts and Sciences, and Co–Director of the Kavli Institute for Bionano Science and Technology — is designing various such liquid–infused polymer systems.

For the current study, they have chosen a solid silicone polymer, the same kind already used in today’s medical tubing, saturated with a liquid, silicone oil. Both components are safe and non–toxic, and are already used in various medical devices and common products like cosmetics.

“The solid silicone tubing is saturated with silicone oil, soaking it up into all of the tiny spaces in its molecular structure so that the two materials really become completely integrated into one,” said Caitlin Howell, Ph.D., a Postdoctoral Researcher at the Wyss Institute and a co–author on the new findings.

It’s this saturation process that makes the liquid–infused polymer so powerful and could result in a material able to withstand conventional sterilization methods and long–lasting use. This is due to the fact that the surface does not lose its slipperiness over time — the silicone oil continuously diffuses to the surface, replenishing itself to replace any oil that is pulled away by liquids flowing against it, such as urine, blood, or gastro–intestinal fluids.

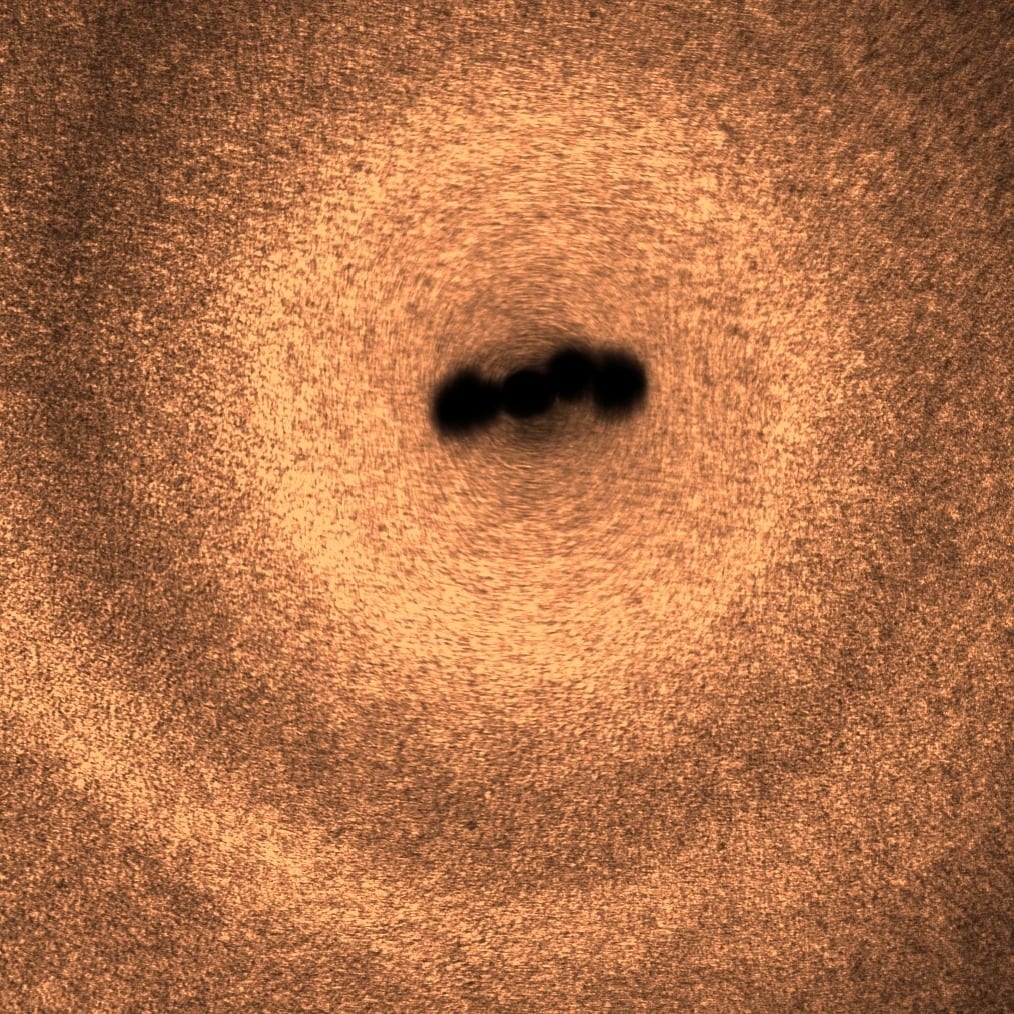

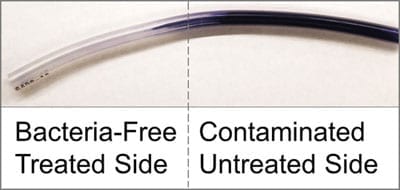

To test the liquid–infused polymer’s effectiveness in biofilm prevention, the study’s lead author Noah MacCallum, an exchange undergraduate student at SEAS, exposed treated and untreated medical tubing to Pseudomonas aeruginosa, Escherichia coli, andStaphylococcus epidermidis, which are common pathogenic bacteria that form biofilms and are frequent culprits of urinary, tissue, and blood infections. The experiment confirmed that the liquid–infused polymer tubing greatly reduced bacterial adhesion and largely eliminated biofilm formation.

As such, the new approach could be leveraged to prevent bacterial infections associated with the biofilm formation on catheters and other medical devices. This preventative aspect is crucial given that once biofilms develop they are remarkably resistant to removal, a problem that is compounded by rising antibiotic resistance in bacteria.

Read more: Novel non-stick material joins portfolio of slippery surface technologies

The Latest on: Liquid–infused polymers

[google_news title=”” keyword=”Liquid–infused polymers” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Liquid–infused polymers

- Lithium-ion vs lithium-polymer batteries: What's the difference?on April 27, 2024 at 5:00 pm

Lithium-ion (Li-ion) battery technology has historically been the power cell of choice for smartphones and a wide range of other portable gadgets too. However, modern smartphones now commonly ...

- These Are The Best Waxes For Your Caron March 27, 2024 at 6:26 am

Infused with polymers, it provides exceptional cover ... providing durable cover against the elements. Griot’s Garage Liquid Gloss Poly Wax combines the ease of application with the durability ...

- Amazing GOURI Treatmenton March 26, 2024 at 5:43 pm

Today, the products on the market are not completely liquid. They are created by mixing polymer-infused material with saline or a special moisturizing eye gel. This leads to uneven distribution ...

- Liquid Crystalline Polymerson March 21, 2024 at 7:11 pm

The 2006 edition of this authoritative guide on liquid crystalline polymer (LCP) science was produced in response to the wealth of new material generated in the field. It takes the reader through the ...

- Liquid vs. Powder Detergent vs. Pods: Which Is Best for Your Laundry?on March 10, 2024 at 5:01 pm

Laundry experts break down the pros and cons of powder vs. liquid detergent, as well as pods. Find out which is right for you. “All detergents have pros and cons,” says LaundryTok expert ...

- Sustainable polymers in liquid formulations – it's time to join the revolutionon May 5, 2022 at 9:16 am

We have teamed up with industry leaders to create a roadmap to sustainable PLFs. Polymers in liquid formulations – or PLFs – play a vital role in our lives. They are found in millions of everyday ...

- PLFs FAQs - what exactly are polymers in liquid formulations?on May 5, 2022 at 9:16 am

Polymers in liquid formulations (PLFs) play a vital role in our lives, yet limited attention has been paid to their environmental impacts. We wanted to change that, so we brought together key ...

- Polymers and Plastic Resins Informationon February 8, 2018 at 2:17 pm

Raw polymer materials are typically produced and sold in liquid form in the case of adhesives, sealants, and resins; or as bulk pellets, powders, granules, or sheet. A major source for polymer ...

- Organic Crystals, Liquid Crystals and Polymerson August 1, 2017 at 5:55 am

As the range of the compiled data is very extensive, volume III/36 is divided into three subvolumes titled III/36A Oxides, III/36B Inorganic substances other than oxides, III/36C Organic crystals, ...

via Bing News