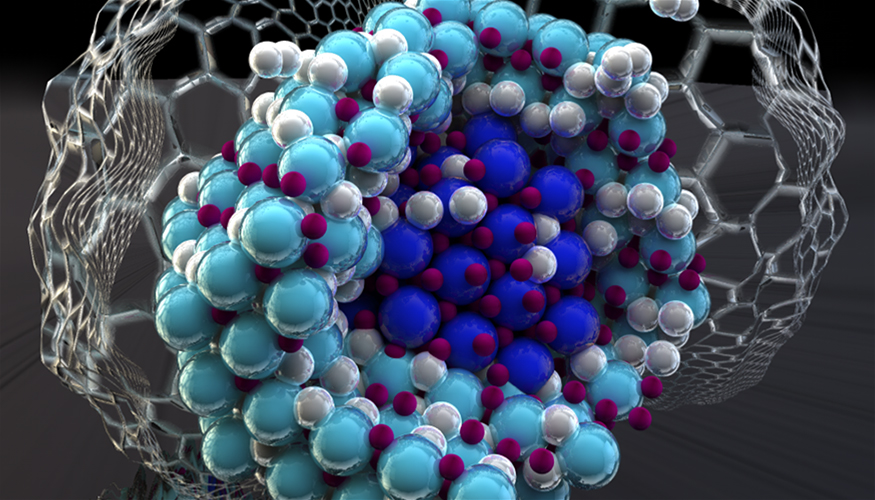

Hydrogenation forms a mixture of lithium amide and hydride (light blue) as an outer shell around a lithium nitride particle (dark blue) nanoconfined in carbon. Nanoconfinement suppresses all other intermediate phases to prevent interface formation, which has the effect of dramatically improving the hydrogen storage performance.

Lawrence Livermore scientists have collaborated with an interdisciplinary team of researchers, including colleagues from Sandia National Laboratories, to develop an efficient hydrogen storage system that could be a boon for hydrogen-powered vehicles.

Hydrogen is an excellent energy carrier, but the development of lightweight solid-state materials for compact, low-pressure storage is a huge challenge.

Complex metal hydrides are a promising class of hydrogen storage materials, but their viability is usually limited by slow hydrogen uptake and release. Nanoconfinement — infiltrating the metal hydride within a matrix of another material such as carbon — can, in certain instances, help make this process faster by shortening diffusion pathways for hydrogen or by changing the thermodynamic stability of the material.

However, the Livermore-Sandia team, in conjunction with collaborators from Mahidol University in Thailand and the National Institute of Standards and Technology, showed that nanoconfinement can have another, potentially more important consequence. They found that the presence of internal “nano-interfaces” within nanoconfined hydrides can alter which phases appear when the material is cycled.

The researchers examined the high-capacity lithium nitride (Li3N) hydrogen storage system under nanoconfinement. Using a combination of theoretical and experimental techniques, they showed that the pathways for the uptake and release of hydrogen were fundamentally changed by the presence of nano-interfaces, leading to dramatically faster performance and reversibility. The research appears on the cover of the Feb. 23 edition of the journal Advanced Materials Interfaces.

“The key is to get rid of the undesirable intermediate phases, which slow down the material’s performance as they are formed or consumed. If you can do that, then the storage capacity kinetics dramatically improve and the thermodynamic requirements to achieve full recharge become far more reasonable,” said Brandon Wood, an LLNL materials scientist and lead author of the paper. “In this material, the nano-interfaces do just that, as long as the nanoconfined particles are small enough. It’s really a new paradigm for hydrogen storage, since it means that the reactions can be changed by engineering internal microstructures.”

The Livermore researchers used a thermodynamic modeling method that goes beyond conventional descriptions to consider the contributions from the evolving solid phase boundaries as the material is hydrogenated and dehydrogenated. They showed that accounting for these contributions eliminates intermediates in nanoconfined lithium nitride, which was confirmed spectroscopically.

Beyond demonstrating nanoconfined lithium nitride as a rechargeable, high-performing hydrogen-storage material, the work establishes that proper consideration of solid–solid nanointerfaces and particle microstructure are necessary for understanding hydrogen-induced phase transitions in complex metal hydrides.

“There is a direct analogy between hydrogen storage reactions and solid-state reactions in battery electrode materials,” said Tae Wook Heo, another LLNL co-author on the study. “People have been thinking about the role of interfaces in batteries for some time, and our work suggests that some of the same strategies being pursued in the battery community could also be applied to hydrogen storage. Tailoring morphology and internal microstructure could be the best way forward for engineering materials that could meet performance targets.”

Original Article: Scientific team develops nano-sized hydrogen storage system to increase efficiency

More from: Lawrence Livermore National Laboratory | Sandia National Laboratories | Mahidol University | National Institute of Standards and Technology

The Latest Updates from Bing News

Go deeper with Bing News on:

Hydrogen storage crystals

- Platinum-linked venture capital provider highlights hydrogen’s ‘irreplaceable’ decarb role

The role of hydrogen in the decarbonisation of the hardest-to-abate sectors of the global economy continues to be described as “irreplaceable” by AP Ventures, the independent venture capital fund that ...

- Hydrogen-Powered Airplanes Face 5 Big Challenges

It can be burned with oxygen to create water, powering a jet, but it has to be stored in liquid form, which means installing high-pressure tanks that keep the highly flammable substance at ...

- Beaulieu: Hydrogen is not the answer

Hydrogen is a very small molecule, and easily leaks through pipelines or other storage infrastructure ... we have been crystal clear; we were fully committed to transitioning our facilities ...

- Beaulieu: Hydrogen is not the answer

Solar power and battery storage are clean energy solutions but “clean hydrogen” and “green biofuels” are misnomers used by Granite Shore Power.

- Magnetic with a pinch of hydrogen: Research team develops new idea to improve the properties of ultra-thin materials

Using adhesive tape, they peeled off a thin layer from a graphite crystal ... The green hydrogen obtained this way could then be used, for example, as energy storage medium for times when there ...

Go deeper with Bing News on:

Hydrogen storage

- IPCL and ES2 collaborate for pilot thermal energy storage project

The two companies launched a thermal storage unit with a 250 KWh capacity. Indian Power Corporation Limited (IPCL) and ES2 Power signed an agreement to launch the 250-kilowatt-hour pilot thermal ...

- Why Attending the 2024 Hydrogen Technology Expo is Essential

Houston, Texas, is poised to become the focal point of the hydrogen and clean energy industry as it prepares to host the Hydrogen Technology Expo North America ...

- Hydrogen Storage Alloy Market Forecast 2024-2034: NiMH Alloys and Nickel Hydride Batteries Hold Significant Market Share

Dublin, May 08, 2024 (GLOBE NEWSWIRE) -- The "Hydrogen Storage Alloy Market - A Global and Regional Analysis: Focus on Application, Type, and Region - Analysis and Forecast, 2024-2034" report has been ...

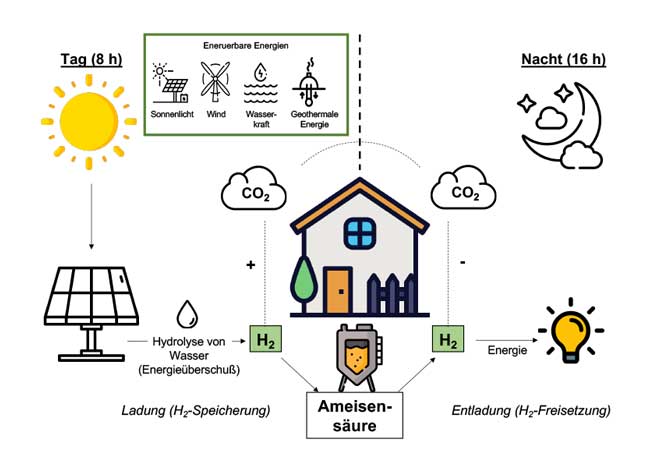

- Powering homes exclusively with hydrogen, solar, batteries

Researchers in Spain has found that combining PV power generation with fuel cells and battery storage may help homes considerably reduce their levelized cost of energy. Their simulation reportedly ...

- Feadship Launches World’s First Hydrogen Fuel Cell-Powered Superyacht

This new, 390-foot-long superyacht (designed by RWD with owner’s representation by Edmiston), can provide carbon-emission-free power from green ...