University of Virginia mechanical engineers and materials scientists, in collaboration with materials scientists at Penn State, the University of Maryland and the National Institute of Standards and Technology, have invented a “switching effect” for thermal conductivity and mechanical properties that can be incorporated into the fabrication of materials including textiles and garments.

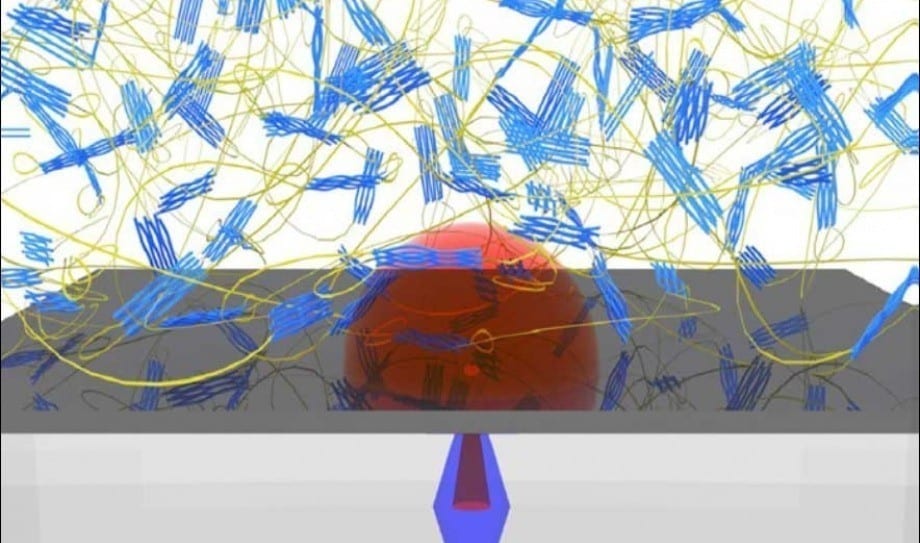

Using heat transport principles combined with a biopolymer inspired by squid ring teeth, the team studied a material that can dynamically regulate its thermal properties – switching back and forth between insulating and cooling – based on the amount of water that is present.

The invention holds great promise for all sorts of new devices and materials with the ability to regulate temperature and heat flow on demand, including the “smart” fabrics.

“The switching effect of thermal conductivity would be ideal for many applications, including athletics,” said John Tomko, a Ph.D. candidate in UVA’s DEPARTMENT OF MATERIALS SCIENCE & ENGINEERING and lead author of an article about the invention published this week in NATURE NANOTECHNOLOGY. “This material has the potential to revolutionize active wear, unleashing the possibility of clothing that can dynamically respond to body heat and regulate temperature. For example, the biopolymer has a low thermal conductivity while dry, essentially storing body heat and keeping the athlete (and his or her muscles!) warm while not active. As soon as the wearer begins to sweat, the material could become hydrated and instantly increase its thermal conductivity, allowing this body heat to escape through the material and cool the athlete down. When the person is done training and the sweat has evaporated, the material could go back to an insulative state and keep the wearer warm again.

“And while it may sound highly specialized and only for professional athletes, it would be equally useful from an apparel company perspective,” said Tomko, whose research is being conducted as part of the EXSITE GROUP led by Professor PATRICK HOPKINS of UVA’s departments of MECHANICAL & AEROSPACE ENGINEERING, Materials Science & Engineering and PHYSICS.

The garments made using this technology would be a step above what is available on the market today because of the materials’ extremely wide range of technical capabilities. For example, polar fleece generally requires different weights to accommodate different combinations of temperatures and activity levels. The new material could accommodate the whole gamut of athletic scenarios within one garment. Fleece is considered breathable, a passive state, but the biopolymer material would actively conduct heat out of the garment.

“While realizing thermally and mechanically smart fabrics is one major advance of this work, the ability to provide such large and reversible modification in the thermal conductivity of a material `on-demand’ has potential game-changing applications,” said Hopkins, Tomko’s Ph.D. advisor and co-lead on this research effort with Professor Melik Demirel at Penn State. “The thermal conductivity of materials is typically assumed to be a static, intrinsic property of a material. What we have shown is that you can ’switch‘ the thermal conductivity of a material in a similar way that you would turn on and off a light bulb via a switch on the wall, only instead of using electricity, we can use water to create this switch. This will allow for dynamic and controllable ways to regulate the temperature and/or heat flow of materials and devices.

“The magnitude of this on/off thermal conductivity ratio is large enough where we can now envision applications including not only smart fabrics, but also more efficient recycling of wasted heat to create electricity, making self-thermally regulating electrical devices, or creating new avenues for wind- and hydropower production.”

The process of creating “programmable” materials could be good news for manufacturers and the environment. Usually textile companies have to rely on different types of fibers and different manufacturing processes to create clothing with varying attributes, but the tunable aspect of these materials means that insulating and cooling attributes can be created from the same process. This could lead to lower manufacturing costs and reduced carbon emissions.

Squid ring teeth, which make programmable materials possible, are an inspiring new avenue of scientific research that were FIRST DISCOVERED AT PENN STATE. These biomaterials contain unique properties such as strength, self-healing and biocompatibility, making them exceptionally suitable for programming at the molecular level, in this case for thermal regulation. This is more good news for the environment, since they can be extracted from the suction cups of squids or can be synthetically produced via industrial fermentation, both sustainable resources.

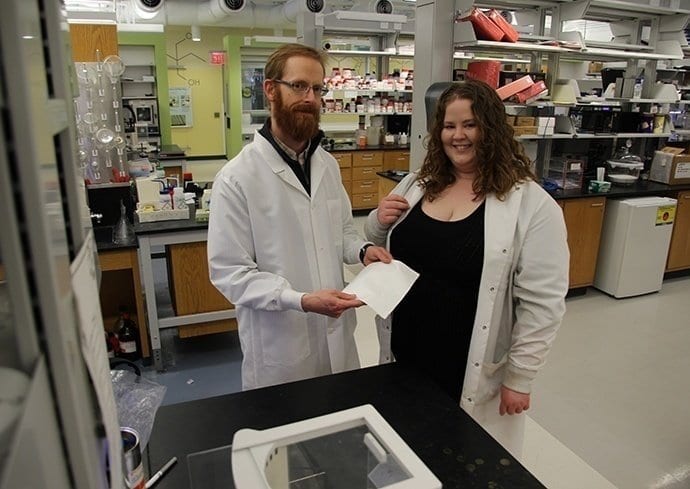

Tomko’s and Hopkins’ collaborators on the research are Abdon Pena-Francesch, former Ph.D. student at Penn State and now a von Humboldt Fellow at the Max Planck Institute in Stuttgart, Germany; Huihun Jung, a doctoral candidate in engineering science and mechanics at Penn State; Madhusudan Tyagi a researcher with the University of Maryland and the National Institute of Standards and Technology; Benjamin D. Allen, assistant research professor of biochemistry and molecular biology at Penn State; and Demirel, professor of engineering science and mechanics and director, Center for Research on Advanced Fiber Technologies at Penn State.

“The beauty and unique power of neutron scattering helped us solve the puzzle of how tandem repeat units really influence the observed thermal conductivity in hydrated samples, as heavy water simply becomes ‘invisible’ to neutrons! We found that the increased and ‘altered’ dynamics of amorphous strands were, actually, responsible for this increased thermal conductivity in hydrated samples,” said the University of Maryland’s Tyagi. “I believe this research is going to change how we study thermal properties of soft matter, particularly proteins and polymers, using neutrons as typically hard condensed matter is where most of the work is done in this regard.”

Tomko and fellow UVA Engineering researchers, along with graduate students from UVA’s Darden School of Business, won first place in a PATAGONIA OUTDOOR APPAREL COMPANY COMPETITION this spring to determine the best ideas for attaining carbon neutrality. Raw materials production is responsible for about 80 percent of Patagonia’s total carbon emissions, largely attributed to the production of polyester fabrics derived from fossil fuels. The UVA team proposed that the company transition to biopolymer textiles, which can be engineered solely from renewable resources. The new materials would look and function better than polyester and wool alternatives without relying on fossil fuel.

Learn more: University of Virginia Multidisciplinary Engineering Team Designs New Technology for Smart Materials

The Latest on: Smart materials

[google_news title=”” keyword=”smart materials” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Smart materials

- Smart Serve Ontario Launches Campaign to provide essential and free mental health services to over 550,000 active Smart Serve certificate holderson May 9, 2024 at 3:00 am

Smart Serve Ontario, a registered charity dedicated to responsible liquor sales and service practices, is taking a crucial step towards improving mental health in the hospitality industry with the ...

- Goodbye to Apple’s Smart Keyboard Folio, the best iPad Pro accessoryon May 8, 2024 at 9:44 am

Sure enough, the Smart Keyboard Folio isn’t compatible with the OLED iPad Pros. The 11-inch version can still be used with the sixth-generation iPad Air, but that’s all. So if you’re set on Apple’s ...

- Apple iPad 2024 All-New Magic Keyboard and Smart Folioon May 8, 2024 at 2:47 am

Apple has released a new Magic Keyboard to complement the launch of the new 2024 iPad Pro iPads powered by Apple's M4 silicon chips ...

- 17 Splurges That Are Actually Smart Buys If You Love Qualityon May 7, 2024 at 6:45 am

Certain high-end items such as mattresses, shoes, and outerwear are actually smart buys that can save you money in the long run.

- Smart labs for bespoke synthesis of nanomaterials are emergingon May 7, 2024 at 6:32 am

In the early 20th century, the development of a catalyst for ammonia synthesis by the Haber-Bosch method took more than 10,000 experiments before it was successful. The development of new materials is ...

- Use AI And Machine Learning To Capitalize On Smart Building Dataon May 3, 2024 at 4:30 am

The same data-driven machine learning principles that power GenAI, when applied to building IoT data, can help organizations optimize well-being and productivity.

- A laser immersion probe for smart inline monitoring of water and wastewateron May 2, 2024 at 1:51 pm

A new type of laser-based immersion probe, which the Fraunhofer Institute for Laser Technology ILT in Aachen is testing as part of projects with industrial partners and users, could pave the way for ...

- Engineers create energy-smart, sustainable bricks from wasteon May 1, 2024 at 6:51 am

For manufacturers, that means saving up to 20 percent on firing temperatures by replacing clay with waste materials in brick production.

- Jean Smart: 'Hacks' character finds it 'so annoying' to growon May 1, 2024 at 2:00 am

Jean Smart and Hannah Einbinder discuss "Hacks" Season 3, premiering Thursday on Max, as Deborah Vance and Ava Daniels reunite and continue to push each other's buttons.

via Bing News