Many tasks in biology require tiny, accurate motion – achieved with expensive hardware. We have used inexpensive, 3D printed parts to make high performance mechanisms for low cost science.

Our best example is a microscope small and cheap enough to be left in an incubator or fume hood for days or weeks. This will enable new science, for example by observing cells as they grow in an incubator. We will improve this microscope’s imaging capabilities (adding fluorescence and phase contrast) and demonstrate its use in an incubator. We will also show that printed mechanisms can be used for other tasks, for example the mechanical manipulation of micropipettes for microinjection or patch clamping.

The Idea

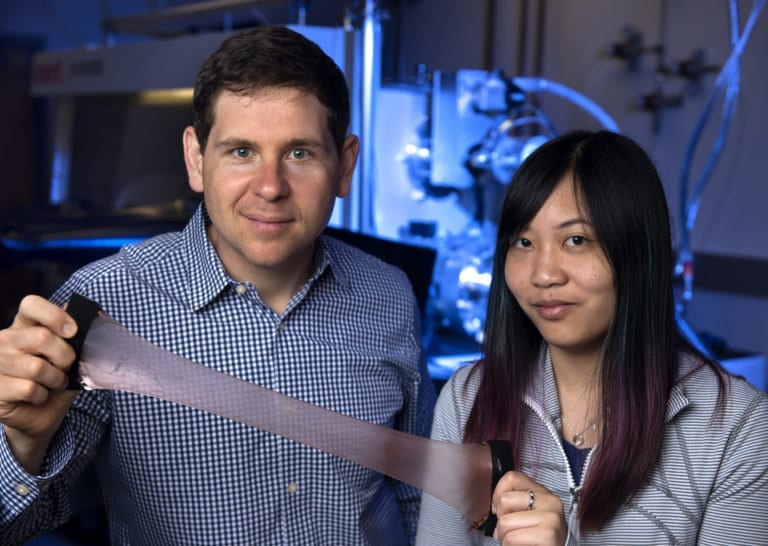

Optical microscopy is fundamental to biology, and relatively high performance microscopes can now be made very cheaply. Positioning the sample and focusing the objective, however, is difficult without expensive translation stages: a microscope is mostly mechanics. Many other tasks in biology require tiny, accurate motion – achieved with expensive hardware such as mechanical micromanipulators and piezoelectric actuators. We have used inexpensive, 3D printed parts to make high performance mechanisms for low cost science, and we propose to apply this technology to problems in synthetic biology.

Our best example is a microscope small and cheap enough to be left in an incubator or fume hood for days or weeks. This will enable new science, for example by observing cells as they grow in an incubator – experiments which are currently impossible to do on a large scale due to the time and resources required. We will improve this microscope’s biological imaging capabilities (adding fluorescence and phase contrast) and demonstrate its use in an incubator at the Light Microscopy Facility in the Cancer Research Institute. This will then allow us to study phototoxicity by monitoring cultures of cells over several days.

Plastic flexure technology could also reduce the cost of mechanical micromanipulators by three orders of magnitude, opening up a range of possibilities. When combined with open-source Arduino microcontrollers, it is even possible to automate these devices for around £100. We will develop and test plastic micromanipulators for microinjection or electrophysiology, and assess their precision and stability. We will also investigate the use of ABS plastic as a potential replacement for PLA, as it has the potential to further improve the performance of printed mechanisms.

Finally, these low cost devices present obvious opportunities for science outreach, and this funding would enable us to create a class set of microscopes that can be taken (or lent) to schools as part of outreach activities, along with some fixed samples and lesson plans for easily-prepared specimens.

Learn more: Open source 3D-printed microscope

The Latest on: 3D printed microscope

[google_news title=”” keyword=”3D printed microscope” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3D printed microscope

- This 3D-Printed Transmission Is an Impressive Piece of Miniature Engineeringon April 28, 2024 at 6:00 am

The planetary-based gearbox functions similarly to an automatic transmission and uses a camshaft to select one of three gears.

- Makers of the world’s largest 3D printer just beat their own recordon April 26, 2024 at 10:43 am

After a five-year reign, the world’s largest 3D printer located at the University of Maine has been usurped—by a newer, larger 3D printer developed at the same school.

- The world’s largest 3D printer is at a university in Maine. It just unveiled an even bigger oneon April 26, 2024 at 8:33 am

The world’s largest 3D printer has created a house that can cut construction time and labor. An even larger printer unveiled on Tuesday may one day create entire neighborhoods.

- The world’s first face-and-eye transplanton April 26, 2024 at 7:15 am

Surgeons have used advanced technology to complete the first face-and-eye transplant. 3D-printed cutting guides were used to access the donor's orbital socket. High-powered microscopes and ...

- 3D Printed Silk Bio-Ink Shows Potential for Knee Meniscus Repairon April 24, 2024 at 7:00 am

Researchers have developed a silk-based bio-ink to 3D print a meniscus for better knee repair and regeneration.

- Technion breakthrough for better drug delivery and tissue implantationon April 23, 2024 at 2:11 pm

Researchers develop ultrasound for non-invasive method for bio-printing live cells and tissues deep within the body.

- SkyWater Technology Is Lowering Barriers To Advanced Chip Packagingon April 23, 2024 at 3:00 am

SkyWater has partnered with Deca Technologies to develop a multi chip packaging capability that will lower the entry barriers to advanced packaging.

- New imaging system at MUSC provides clear, detailed view for difficult surgerieson April 22, 2024 at 3:59 am

A new digital imaging system at MUSC replaces microscopes for intricate surgeries in the brain and spine. One Summerville family is already thankful for it.

- Dental Implant Market Economic Projections Soar To USD 9.0 Billion By 2033, With 7.77% CAGRon April 19, 2024 at 7:15 am

According to a recent report by Market.us, the Global Dental Implants Market size is expected to be worth around USD 9.0 Billion by 2032 from USD 4.32 Billion in 2022, growing at a CAGR of 7.77% ...

- Fashion isn’t just for the eyes: Upcoming Met Gala exhibit aims to be a multi-sensory experienceon April 15, 2024 at 9:00 am

Fashion, most would surely agree, is meant to be seen. Not heard, and certainly not smelled. But Andrew Bolton, the curatorial mastermind behind the blockbuster fashion exhibits at ...

via Bing News