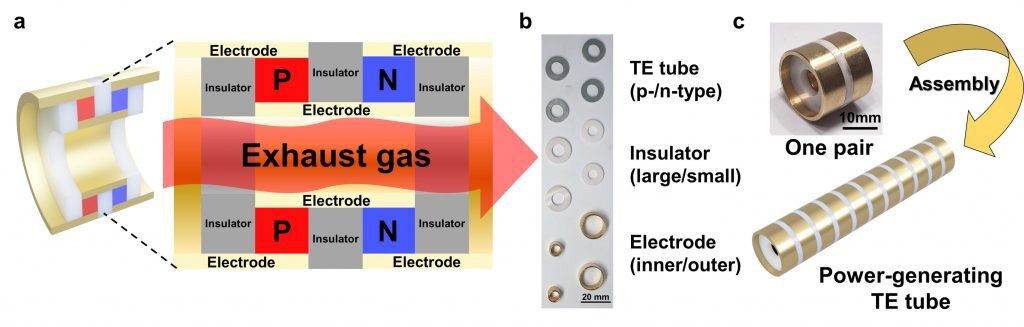

Figure 1. 3D printing of power-generating TE tube. a) Scheme showing the power-generating TE tube made of the 3D-printed p-type and n-type PbTe tubes at the front view. b) Photograph showing the components for the module assembly. c) Photograph of the fabricated power-generating TE tube chipping unipair of p-type and n-type PbTe legs and schematic model of a power-generating tube chipping ten pairs of TE legs assembled from the fabricated unit module.

A joint research team, affiliated with UNIST has announced that they have successfully developed a thermoelectric technology to produce power-generating tubes using 3D printing techniques. Researchers found that the tube-shaped device is more effective than conventional devices.

This breakthrough has been jointly led by Professor Han Gi Chae and Professor Jae Sung Son from the Department of Materials Science and Engineering, and Professor Sung Youb Kim from the Department of Mechanical Engineering at UNIST.

“Through this research, we will be able to effectively convert heat generated by factory chimneys, the most common type of waste heat source, into electricity,” said Professor Son. He said this is because the existing thermoelectric devices were in rectangular parallelepiped shapes.

In this study, researchers created the thermoelectric tube using a 3D printed ink made of lead (Pb) and tellurium (Te). Metal particles were mixed inside a glycerol solvent to provide viscoelasticity, a status that exhibits both viscous and elastic characteristics. The tube has a high thermoelectric performance at temperatures between 400 and 800 degrees Celsius, which is the temperature range of a car’s exhaust gases. The tube shape makes it more effective in collecting heat than a conventional cuboid type.

“If we use 3D printing technology in the production of thermoelectric materials, we will be able to overcome limits of conventional materials,” said Professor Chae. “The new technology for providing viscoelastic characteristics to 3D printed materials will be used in various other sectors.”

Original Article: New Study Unveils Thermoelectric Ink that Turns Car Exhaust Pipes into Power Generators

More from: Ulsan National Institute of Science and Technology | Chonnam National University | Korea Electrotechnology Research Institute

The Latest Updates from Bing News & Google News

Go deeper with Bing News on:

3D printed power-generating tubes

- The world’s largest 3D printer is at a university in Maine. It just unveiled an even bigger one

The university that boasts the world’s largest 3D printer developed one even bigger. And it’s poised to help tackle one of America’s biggest problems of all.

- Empowering Creativity: 10 Innovative Tech Gadgets to Spark Imagination in Kids

In a world driven by technology, fostering creativity in children has become more important than ever. Fortunately, with the rise of innovative tech gadgets, parents now have a plethora of tools at ...

- University of Maine is using giant 3D printer to build homes

University of Maine, which boasts the world’s largest 3D printer, developed one even bigger that may one day create entire neighborhoods. The thermoplastic polymer printer was dubbed the “Factory of ...

- 10 Sci-Fi Gadgets That Would Make Life So Much Easier

Even those communicators weren't as advanced as the smartphones we have today, so occasionally, reality finds a way to improve upon what sci-fi writers envisioned decades previously. Of course, there ...

- Inclusion Drives Innovation: The Power Of Diverse Perspectives

When organizations foster diverse, inclusive workplace cultures, they're better equipped for making innovative solutions that drive success.

Go deeper with Google Headlines on:

3D printed power-generating tubes

[google_news title=”” keyword=”3D printed power-generating tubes” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]

Go deeper with Bing News on:

Thermoelectric technology

- Ion thermoelectric conversion devices for near room temperature

The electrode sheet of a thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction to ...

- What is thermoelectric cooling, which removes heat from an object by passing an electric current between a semiconductor and a metal?

Thermoelectric cooling, a technology that uses the phenomenon that heat is transferred to one side when an electric current is passed through the junction of different semiconductors and metals ...

- Global Solid State Cooling Market Report 2024-2029: Thermoelectric Cooling Technology To Capture Largest Share Of Solid State Cooling Market In 2029

Thermoelectric Cooling Technology to Capture Largest Share of Solid State Cooling Market in 2029 Healthcare Vertical to Account for Largest Market Share in 2029 Asia-Pacific Accounted for Largest ...

- Global Solid State Cooling Market Report 2024-2029: Thermoelectric Cooling Technology to Capture Largest Share of Solid State Cooling Market in 2029

Thermoelectric technology in solid state cooling market to account for the highest market share The solid-state cooling market for thermoelectric technology is propelled by several key factors ...

- Torras Unveils A Comprehensive Guide: How Neck Air Conditioners Work

Neck air conditioners are a revolutionary innovation designed to provide personal cooling in various environments. These portable devices are gaining popularity due to their ability to offer on-the-go ...

Go deeper with Google Headlines on:

Thermoelectric technology

[google_news title=”” keyword=”thermoelectric technology” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]