Exposing packaged liquids, fruits and vegetables to an electrical field for just minutes might eliminate all traces of foodborne pathogens on those foods, according to a Purdue University study.

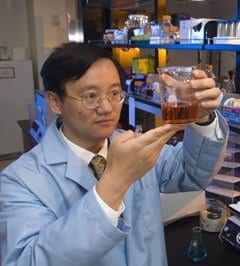

Kevin Keener, a professor of food science, looks for new ways to kill harmful bacteria, such as E.coli and Salmonella, that contaminate foods and cause serious illnesses and deaths. His method uses electricity to generate a plasma, or ionized gas, from atmospheric gases inside the food package.

This process creates a wide variety of bacteria-killing molecules including ozone, nitrogen oxides, hydrogen peroxide and others. These molecules only exist for a few hours and then revert back to the original atmospheric gas, leaving a bacteria-free product.

In findings published in the Journal of Applied Microbiology, Keener and researchers at the Dublin Institute of Technology demonstrated that sealed-package atmospheric plasma works well to kill bacteria in growth media. Their experiments showed that bacteria on these surfaces were eliminated with 20 seconds of treatment and 24 hours of exposure to the gases it creates. Keener said the cost of the process should be comparable to current chemical and heat treatments used to sanitize foods.

“Even in the most resistant bacteria-growing media, 45 seconds of treatment gave us complete elimination of the E. coli,” Keener said. “Under a microscope, we saw holes forming in the cell walls of the bacteria.”

Adapting the technology for liquids could allow development of portable devices to clean drinking water in areas with contamination or that lack other purification methods. It could also allow food processors to bottle juices without first heating them, a process widely used to kill bacteria that can alter products.

“This could be developed to allow you to achieve something similar to pasteurization without the heat and quality changes that occur with that process,” Keener said.

In Europe, especially, new methods are being sought as alternatives to washing foods in chlorine baths.

“Chlorine water works well on hard surfaces. But there can be issues if bacteria get inside organic matter on the produce, making chlorine ineffective,” Keener said.

Keener is working with researchers at Dublin Institute of Technology, National Centre for Plasma Science and Technology at Dublin City University in Ireland, and Innovació i Recerca Industrial i Sostenible (IRIS) in Spain to develop a precommercial system for larger-scale decontamination testing. After that, he would like to build a commercial system that could be used in food-processing plants.

Future research will also consider how the process affects food quality.

The Latest Bing News on:

Killing foodborne pathogens

- RECIPE: Simple science guarantees moist and tender sheet pan turkey supperon May 1, 2024 at 5:58 am

The chief complaint with cooked ground turkey is that it is as dry as sawdust. But ground turkey has a lot going for it. It’s high in protein and low in fat and calories. The flavor is mild and ...

- Bird flu concerns increase caution around raw milk and other unpasteurized dairy productson May 1, 2024 at 3:32 am

Recent studies confirm pasteurization eliminates bird flu in milk, though health experts warn against consuming raw dairy amidst an avian influenza surge.Sara Moniuszko reports for CBS News.In ...

- US to test ground beef in states with dairy cows infected with bird flu. What to know.on April 30, 2024 at 1:37 pm

Federal officials are looking to verify the safety of beef and milk after 34 dairy cattle herds in nine states tested positive for the H5N1 virus.

- Bird flu risk prompts warnings against raw milk, unpasteurized dairy productson April 29, 2024 at 3:29 pm

Unlike pasteurized milk, which undergoes a process that kills harmful bacteria, experts say raw milk can carry pathogens that make you sick.

- Publisher’s Platform: What you need to know about Noroviruson April 28, 2024 at 9:00 pm

What Is Norovirus? When someone talks about having “the stomach flu,” they are probably describing acute-onset gastroenteritis caused by one of the ...

- WHO Confirms H5N1 In Raw Cow Milk, Here's Why You Should Drink Pasteurised Milkon April 27, 2024 at 3:48 am

The presence of H5N1 in raw cow milk highlight the benefits of pasteurised milk such as safety from harmful bacteria ...

- WSU researchers expose ‘bacterial vampirism’ in some foodborne pathogenson April 26, 2024 at 5:00 pm

A recent study published in the journal eLife led by researchers from WSU reveals that certain bacteria, including some foodborne bacteria ... for targeted interventions to combat these deadly ...

- Colorado won’t legalize raw milk this year after proposal to allow direct sales to consumers spoils in the legislatureon April 25, 2024 at 10:15 am

Colorado has some of the strictest raw milk laws in the West, requiring people to buy shares in a cow or goat herd if they want to get unpasteurized milk ...

- Climate change is killing us - in more ways than oneon April 23, 2024 at 6:56 pm

We've all heard about climate change's effect on our planet, but what about its catastrophic impact on human health? We've all heard about climate change's effect on our planet - but do you know about ...

- Biologists rescue sick sawfish, hoping for clues in Florida Keys fish-kill mysteryon April 12, 2024 at 3:11 pm

And necropsy data taken from dead fish samples so far has not turned up any communicable pathogens ... kill. For the erratic, spinning behavior, scientists have speculated it may be related to a toxin ...

The Latest Google Headlines on:

Killing foodborne pathogens

[google_news title=”” keyword=”killing foodborne pathogens” num_posts=”10″ blurb_length=”0″ show_thumb=”left”] [/vc_column_text]The Latest Bing News on:

Foodborne pathogens

- Bird Flu Highlights Concerns Around Raw Milkon May 1, 2024 at 11:39 am

Raw milk, in the best of times, “is one of the one of the riskiest foods that we have,” said Benjamin Chapman, a professor and food safety specialist at North Carolina State University. But with cases ...

- It’s now illegal to sell (some) raw chicken products with Salmonellaon May 1, 2024 at 9:30 am

The build-up to the landmark decision began in earnest in 2022 when the USDA’s Food Safety and Inspection Service (FSIS) released a proposed regulatory framework for a new strategy to control ...

- USDA to test ground beef for bird flu. Is it safe to eat?on May 1, 2024 at 7:55 am

While the USDA does not believe the meat will contain bird flu, it's possible. Last week, it was announced the U.S. Food and Drug Administration found non-infectious remnants of the bird flu virus in ...

- Clinton County restaurant inspections: Raw chicken, beef meats stored above spinach, cheese in cooleron May 1, 2024 at 6:30 am

ST. JOHNS — When county health inspectors visit local restaurants, they document problems that need addressing to meet Clinton County's health code. The most serious problems are considered priority ...

- Bird flu concerns increase caution around raw milk and other unpasteurized dairy productson May 1, 2024 at 3:32 am

Recent studies confirm pasteurization eliminates bird flu in milk, though health experts warn against consuming raw dairy amidst an avian influenza surge.Sara Moniuszko reports for CBS News.In ...

- Partnership Opportunities to Transform Food Systemson April 30, 2024 at 2:18 pm

This report explores how public-private partnerships can help transform global food systems to be more sustainable, efficient, and equitable while adapting to climate change and meeting the increasing ...

- US to test ground beef in states with dairy cows infected with bird flu. What to know.on April 30, 2024 at 1:37 pm

Federal officials are looking to verify the safety of beef and milk after 34 dairy cattle herds in nine states tested positive for the H5N1 virus.

- Bird flu risk prompts warnings against raw milk, unpasteurized dairy productson April 29, 2024 at 3:29 pm

Unlike pasteurized milk, which undergoes a process that kills harmful bacteria, experts say raw milk can carry pathogens that make you sick.

- State officials warn consumers about pathogen in raw milk; at least one person illon April 28, 2024 at 9:00 pm

People in Schuyler County New York are again being warned not to consume unpasteurized, raw milk from Sunset View Creamer because of contamination with ...

- WSU researchers expose ‘bacterial vampirism’ in some foodborne pathogenson April 26, 2024 at 5:00 pm

A recent study published in the journal eLife led by researchers from WSU reveals that certain bacteria, including some foodborne bacteria ... particularly among individuals with inflammatory bowel ...

The Latest Google Headlines on:

Foodborne pathogens

[google_news title=”” keyword=”foodborne pathogens” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]