For about $300 in equipment costs, anyone can produce working electrical circuits in the 60 seconds it takes to print them.

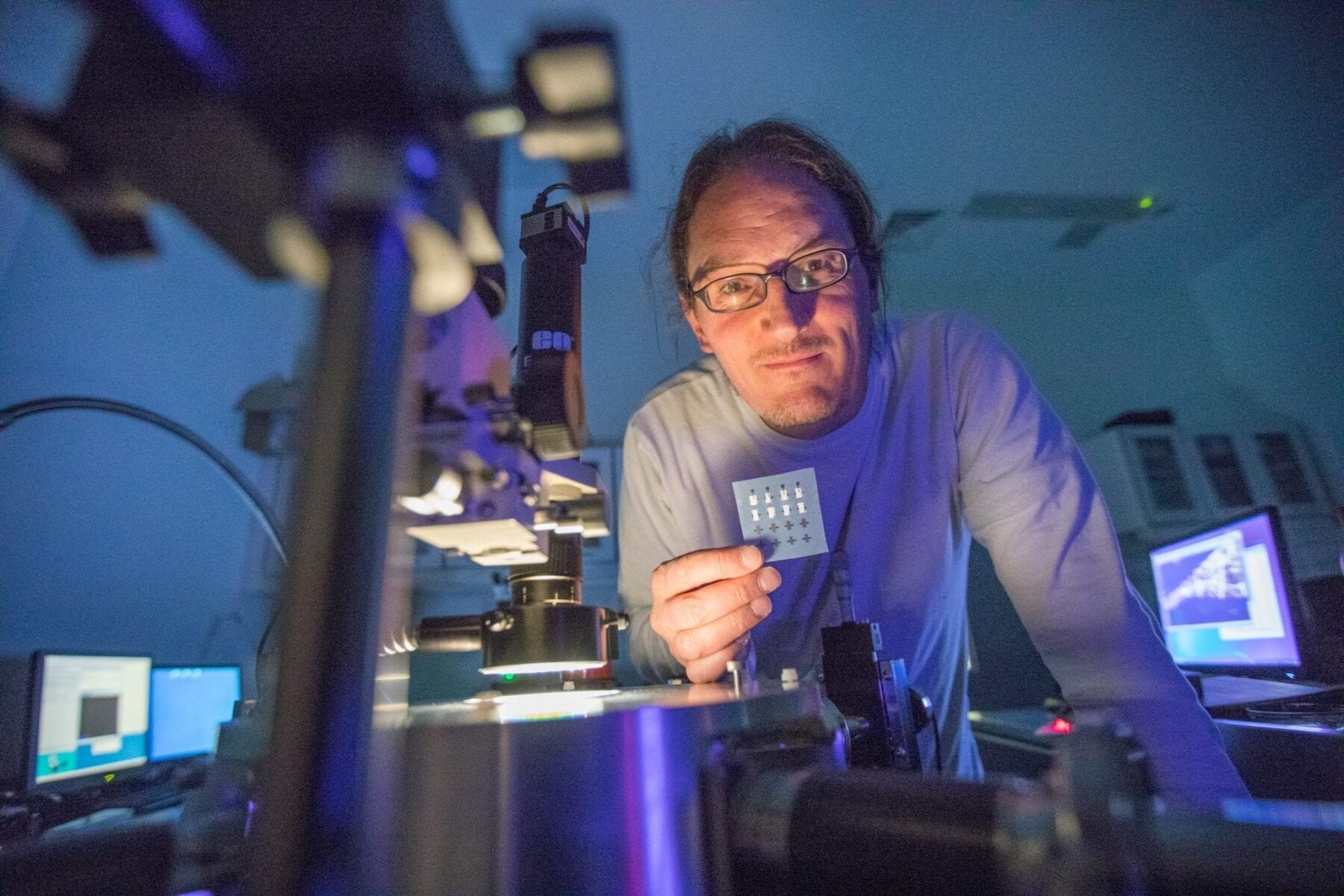

Researchers from Georgia Tech, the University of Tokyo and Microsoft Research have developed a novel method to rapidly and cheaply make electrical circuits by printing them with commodity inkjet printers and off-the-shelf materials. For about $300 in equipment costs, anyone can produce working electrical circuits in the 60 seconds it takes to print them.

The technique, called instant inkjet circuits, allows the printing of arbitrary-shaped conductors onto rigid or flexible materials and could advance the prototyping skills of non-technical enthusiasts and novice hackers.

“We believe there is an opportunity to introduce a new approach to the rapid prototyping of fully custom-printed circuits,” said Gregory Abowd, Regents’ Professor in the School of Interactive Computing at Georgia Tech and an investigator in the study. “Unlike existing methods for printing conductive patterns, conductivity in our technique emerges within a few seconds and without the need for special equipment.”

Recent advances in chemically bonding metal particles allowed the researchers to use silver nanoparticle ink to print the circuits and avoid thermal bonding, or sintering, a time-consuming and potentially damaging technique due to the heat. Printing the circuits on resin-coated paper, PET film and glossy photo paper worked best. Researchers also made a list of materials to avoid, such as canvas cloths and magnet sheets.

“Everything we introduced in our research is available in the market and makes it possible for people to try this at home,” said Yoshihiro Kawahara, Associate Professor at the University of Tokyo and the primary investigator who developed the methodology while in Atlanta. “The method can be used to print circuit boards, sensors and antennas with little cost, and it opens up many new opportunities.”

To make the technique possible, researchers optimized commercially available tools and materials including printers, adhesive tape and the silver ink. Designing the circuit itself was accomplished with desktop drawing software, and even a photocopy of a drawing can produce a working circuit.

Once printed, the circuits can be attached to electronic components using conductive double-sided tape or silver epoxy adhesive, allowing full-scale prototyping in mere hours. The homemade circuits might allow tinkerers to quickly prototype crude calculators, thermostat controls, battery chargers or any number of electronic devices.

“Using this technology in the classroom, it would be possible to introduce students to basic electronics principles very cheaply, and they could use a range of electronic components to augment the experience,” said Steve Hodges, a team member from Microsoft Research.

Go deeper with Bing News on:

Inkjet-Based Circuits

- Fujifilm Launches Nanoimprint Resist Compatible with Nanoimprint Lithography

Contributes to cost reduction and power saving in the leading-edge semiconductors manufacturingTOKYO - April 30, 2024 — FUJIFILM Corporation ...

- Watch: Sending a Hyena to Dinner in Animated Short 'The Debutante'

This short premiered at film festivals back in 2022 and has been tour the fest circuit ever since ... at a dreaded dinner dance being held in her honour… The Debutante is based on a short story ...

- Specialty Inks Market To Reach USD 572.9 Million By 2032 | DataHorizzon Research

Variants like UV-curable and water-based inks within the specialty category boast exceptional ... Conductive inks, for instance, are gaining traction for their applications in printed circuits, RFID ...

- Conductive Ink Market Is Encouraged to Reach USD 5.6 Billion by 2033 at a CAGR of 6.3%

According to Market.us, the Conductive Ink Market size is projected to surpass around USD 5.6 billion by 2033, from USD 3.5 billion in 2023, and it is poised to reach a registered CAGR of 6.3% from ...

- Masters contender’s chest has 2 words tattooed on it. Here’s inspirational reason why

Masters contender Matthieu Pavon’s chest has two words tattooed on it. He explained the inspirational reason why at Augusta National.

Go deeper with Google Headlines on:

Inkjet-Based Circuits

[google_news title=”” keyword=”Inkjet-Based Circuits” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]

Go deeper with Bing News on:

3D printed circuits

- Specialty Inks Market To Reach USD 572.9 Million By 2032 | DataHorizzon Research

and 3D printing. Conductive inks, for instance, are gaining traction for their applications in printed circuits, RFID tags, and wearable electronics. Similarly, incorporating specialty inks into smart ...

- IDTechEx Report Unveils 3D Electronics Status and Opportunities

D electronics is an emerging manufacturing approach that enables electronics to be integrated within or onto the surface of objects. 3D electronic manufacturing techniques empower new features, ...

- Researchers 3D print key components for a point-of-care mass spectrometer

By 3D printing the device instead ... They also created a low-cost, printed circuit board with built-in digital microfluidics, which the emitter is soldered to. The addition of digital microfluidics ...

- Researchers 3D print key components for a point-of-care mass spectrometer

Researchers 3D printed a miniature ionizer ... They also created a low-cost, printed circuit board with built-in digital microfluidics, which the emitter is soldered to. The addition of digital ...

- These futuristic 3D-printed shoes mould to your feet and could hit the market soon

The Evolve AI shoes are fitted with a 3D-printed circuit board, which contains data-collecting sensors. This EU-funded project is a collaboration between multiple companies, including Assa Ashuach's ...

Go deeper with Google Headlines on:

3D printed circuits

[google_news title=”” keyword=”3D printed circuits” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]