- Image via Wikipedia

Lithium-ion batteries start to take on the big stuff

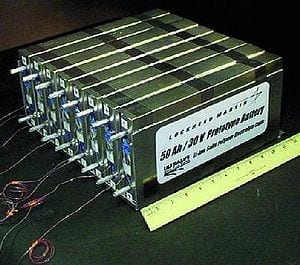

ALMOST every portable device that uses electricity has benefited from the development of rechargeable lithium-ion batteries. They hold more charge in a lighter package (lithium is the lightest metal) and they have boosted the performance of mobile phones, laptop computers, cameras and power tools, and made electric cars and even small electric aircraft practical. But there are some drawbacks. They need constant monitoring by external electronics to stop them charging and discharging too rapidly, for if they do the excess heat damages the battery and, in rare cases, can start a fire. Despite this, one company thinks lithium-ion batteries can now be made robust enough to power some really big, demanding kit—such as tugboats, dockside cranes and super-yachts.

Such marine applications are what got Corvus Energy, of Vancouver, interested in powerful lithium-ion batteries, but the firm is also looking into using them to run equipment like the chillers in delivery lorries and as backup for electrical generators. It has, for example, just won an order to provide a 2.2 megawatt-hour battery the size of a shipping container for use in tests to back up a Chinese coal-fired power station.

Corvus’s batteries are a lot meatier than the ones used in consumer products, but they are built in a similar way. The building blocks of lithium-ion batteries are individual cells. Each cell consists of two electrodes separated by an electrolyte, often a polymer gel. When the battery is being charged, lithium ions migrate from the positive electrode, which is made from a lithium-based material, through the electrolyte to the negative electrode, which is usually made of carbon. When the thing is discharged, the ions flow back and in the process cause a current to flow in an external circuit attached to the battery.

The positive electrodes are often made from lithium iron phosphate. Corvus, however, uses lithium nickel manganese cobalt (NMC) because it provides a greater energy density. The result, says Brent Perry, the company’s boss, is that the cells are 22% more powerful than ones that use iron phosphate. The cells are made for Corvus by Dow Kokam, a joint venture set up in 2009 by two American companies, Dow Chemical and Townsend Kokam, to produce advanced batteries.

Corvus assembles its cells into standard 6.2 kilowatt-hour modules, which can be fitted together to make batteries capable of storing several megawatt-hours of energy—more than 40 megawatt-hours is technically possible. (To compare, Nissan’s new electric car, the Leaf, comes with a 24 kilowatt-hour battery.) Each module is fitted with its own, personal electronic management system to optimise its charging and discharging rates. The result, says the company, is that a module can be charged from flat in as little as 30 minutes and is able to discharge its full 6.2 kilowatt-hours in just six minutes.

Related articles

- Degraded Electrodes Observed In Aging Batteries (hardware.slashdot.org)

- DARPA’s Future Li-ion Batteries Will Be Smaller Than Grains of Salt (popsci.com)