Team uses 3-D printing to produce human cartilage, offering a potent new research tool and advancing treatment opportunities for osteoarthritis and battlefield injuries

In a significant step toward reducing the heavy toll of osteoarthritis around the world, scientists have created the first example of living human cartilage grown on a laboratory chip. The researchers ultimately aim to use their innovative 3-D printing approach to create replacement cartilage for patients with osteoarthritis or soldiers with battlefield injuries.

“Osteoarthritis has a severe impact on quality of life, and there is an urgent need to understand the origin of the disease and develop effective treatments” said Rocky Tuan, Ph.D., director of the Center for Cellular and Molecular Engineering at the University of Pittsburgh School of Medicine, member of the American Association of Anatomists and the study’s senior investigator. “We hope that the methods we’re developing will really make a difference, both in the study of the disease and, ultimately, in treatments for people with cartilage degeneration or joint injuries.”

Osteoarthritis is marked by a gradual disintegration of cartilage, a flexible tissue that provides padding where bones come together in a joint. Causing severe pain and loss of mobility in joints such as knees and fingers, osteoarthritis is one of the leading causes of physical disability in the United States. It is estimated that up to 1 in 2 Americans will develop some form of the disease in their lifetime.

Although some treatments can help relieve arthritis symptoms, there is no cure. Many patients with severe arthritis ultimately require a joint replacement.

Tuan said artificial cartilage built using a patient’s own stem cells could offer enormous therapeutic potential. “Ideally we would like to be able to regenerate this tissue so people can avoid having to get a joint replacement, which is a pretty drastic procedure and is unfortunately something that some patients have to go through multiple times,” said Tuan.

In addition to offering relief for people with osteoarthritis, Tuan said replacement cartilage could also be a game-changer for people with debilitating joint injuries, such as soldiers with battlefield injuries. “We really want these technologies to help wounded warriors return to service or pursue a meaningful post-combat life,” said Tuan, who co-directs the Armed Forces Institute of Regenerative Medicine, a national consortium focused on developing regenerative therapies for injured soldiers. “We are on a mission.”

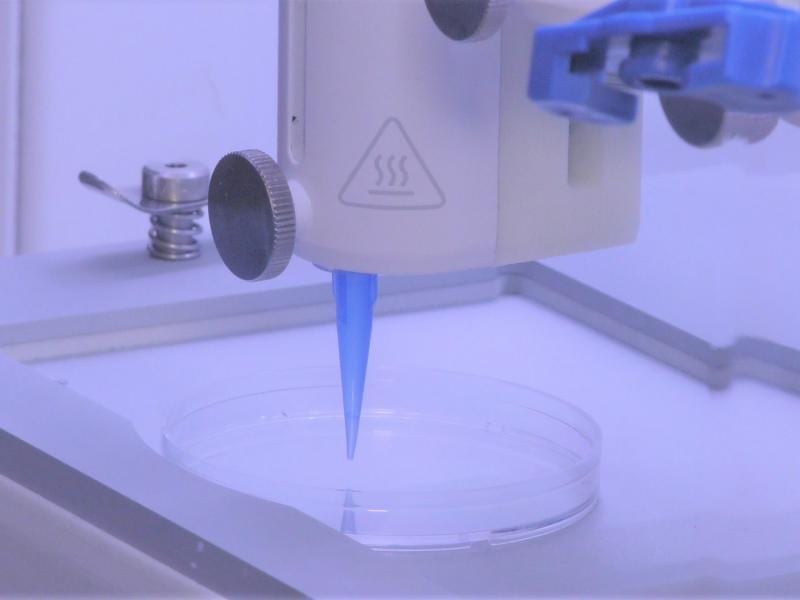

Creating artificial cartilage requires three main elements: stem cells, biological factors to make the cells grow into cartilage, and a scaffold to give the tissue its shape. Tuan’s 3-D printing approach achieves all three by extruding thin layers of stem cells embedded in a solution that retains its shape and provides growth factors. “We essentially speed up the development process by giving the cells everything they need, while creating a scaffold to give the tissue the exact shape and structure that we want,” said Tuan.

The ultimate vision is to give doctors a tool they can thread through a catheter to print new cartilage right where it’s needed in the patient’s body. Although other researchers have experimented with 3-D printing approaches for cartilage, Tuan’s method represents a significant step forward because it uses visible light, while others have required UV light, which can be harmful to living cells.

In another significant step, Tuan has successfully used the 3-D printing method to produce the first “tissue-on-a-chip” replica of the bone-cartilage interface. Housing 96 blocks of living human tissue 4 millimeters across by 8 millimeters deep, the chip could serve as a test-bed for researchers to learn about how osteoarthritis develops and develop new drugs. “With more testing, I think we’ll be able to use our platform to simulate osteoarthritis, which would be extremely useful since scientists really know very little about how the disease develops,” said Tuan.

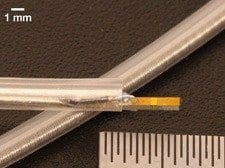

As a next step, the team is working to combine their 3-D printing method with a nanofiber spinning technique they developed previously. They hope combining the two methods will provide a more robust scaffold and allow them to create artificial cartilage that even more closely resembles natural cartilage.

The Latest on: 3-D printed human cartilage

[google_news title=”” keyword=”3-D printed human cartilage” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3-D printed human cartilage

- 3D Printed Wearable Industry Set to Reach USD 10,246.60 Million by 2033: Anticipating a 9.20% CAGR | FMIon May 9, 2024 at 11:47 pm

The global market revenue for the 3D printed wearable market is anticipated to reach USD 10,246.6 million by 2033, with a modest CAGR of 9.2% over the forecast period. The market is currently valued ...

- These 3-D printed coffee cups are earth friendlyon April 25, 2024 at 5:00 pm

These 3-D printed coffee cups are sustainable ... Healed Itself in an Experiment That Stunned Scientists 29 common human foods you may not realize are poisonous to your dog Could You Possess ...

- How 3D printing is changing science fiction to facton April 17, 2024 at 5:00 am

We acknowledge Aboriginal and Torres Strait Islander peoples as the First Australians and Traditional Custodians of the lands where we live, learn and work.

- Scientists 3D-print human ear grafts to counter congenital malformationon April 1, 2024 at 5:51 am

Researchers have created an artificial human ear that “looks ... The team then placed the sterilized cartilage onto ear-shaped plastic scaffolds. The 3D printing technique led to the creation ...

- 3D Printed Cartilage Ushers In Ear-a Of Custom Body Partson June 29, 2022 at 12:40 am

If we could 3D print new custom ... form of a fully-developed human ear. The overshell is intended to be absorbed by the body over time, leaving the printed cartilage structure behind.

- Manufacturing Human Organson September 9, 2021 at 5:04 pm

The hand, which would take six hours to create using conventional 3D-printing methods, demonstrates what engineers at the University at Buffalo say is progress toward 3D-printing human tissue and ...

- 3d printed speakeron April 28, 2021 at 5:00 pm

It’s a popular setup as human ... up to 3 A is specified, providing plenty of volume when needed. The speakers themselves consist of 3″ drivers mounted in attractive 3D-printed shells, with ...

- Just Press Printon March 1, 2020 at 6:46 pm

Indeed, NASA is testing a 3-D printer on the ... one day transplanting human organs printed from a patient’s own cells. “That’s the ultimate goal of 3-D bio-printing,” says Jennifer ...

- 3-D printed robot taught itself to skate!on February 6, 2019 at 4:00 pm

BBC Click reporter Paul Carter tries out the Atom Limbs prosthetic with 'full range of human motion'. Jason lost his arm in an accident in 2012, and he's been working with Atom Limbs to test their ...

- Scientists Use 3-D Printers to Make Body Partson February 20, 2018 at 4:23 am

Scientists are exploring that futuristic vision by using special 3-D printers to make living ... can’t be made in this way? Printing at least parts of the human heart should be possible, Atala ...

via Bing News