The only reinforcing material that is stronger than cellulose nanocrystals is a carbon nanotube, which costs about 100 times as much

The Forest Products Laboratory of the US Forest Service has opened a US$1.7 million pilot plant for the production of cellulose nanocrystals (CNC) from wood by-products materials such as wood chips and sawdust. Prepared properly, CNCs are stronger and stiffer than Kevlar or carbon fibers, so that putting CNC into composite materials results in high strength, low weight products. In addition, the cost of CNCs is less than ten percent of the cost of Kevlar fiber or carbon fiber. These qualities have attracted the interest of the military for use in lightweight armor and ballistic glass (CNCs are transparent), as well as companies in the automotive, aerospace, electronics, consumer products, and medical industries.

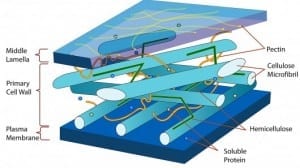

Cellulose is the most abundant biological polymer on the planet and it is found in the cell walls of plant and bacterial cells. Composed of long chains of glucose molecules, cellulose fibers are arranged in an intricate web that provides both structure and support for plant cells. The primary commercial source for cellulose is wood, which is essentially a network of cellulose fibers held together by a matrix of lignin, another natural polymer which is easily degraded and removed.

Wood pulp is produced in a variety of processes, all of which break down and wash away the lignin, leaving behind a suspension of cellulose fibers in water. A typical cellulose wood fiber is only tens of microns wide and about a millimeter long.

The cellulose in wood pulp, when dry, has the consistency of fluff or lint – a layer of wood pulp cellulose has mechanical properties reminiscent of a wet paper towel. Not what you might expect to be the source of one of the strongest materials known to Man. After all, paper is made from the cellulose in wood pulp, and doesn’t show extraordinary strength or stiffness.

Further processing breaks the cellulose fibers down into nanofibrils, which are about a thousand times smaller than the fibers. In the nanofibrils, cellulose takes the form of three-dimensional stacks of unbranched, long strands of glucose molecules, which are held together by hydrogen bonding. While not being “real” chemical bonds, hydrogen bonds between cellulose molecules are rather strong, adding to the strength and stiffness of cellulose nanocrystals.

via Gizmag – Brian Dodson