Can an industrial robot succeed both at removing the breast fillet from a chicken, and at the same time get more out of the raw materials? This is one of the questions to which researchers working on the CYCLE project now have the answer.

They have built a fully-functional robot in the lab to automate the process of extracting breast fillets from chickens. This is a task normally performed by skilled human hands. “Our aim is to automate absolutely everything we can think of on the food production line”, says Ekrem Misimi at SINTEF. This will make Norwegian food production more sustainable, both in terms of profitability and utilisation of raw materials.

Sharp-eyed robot with nimble fingers

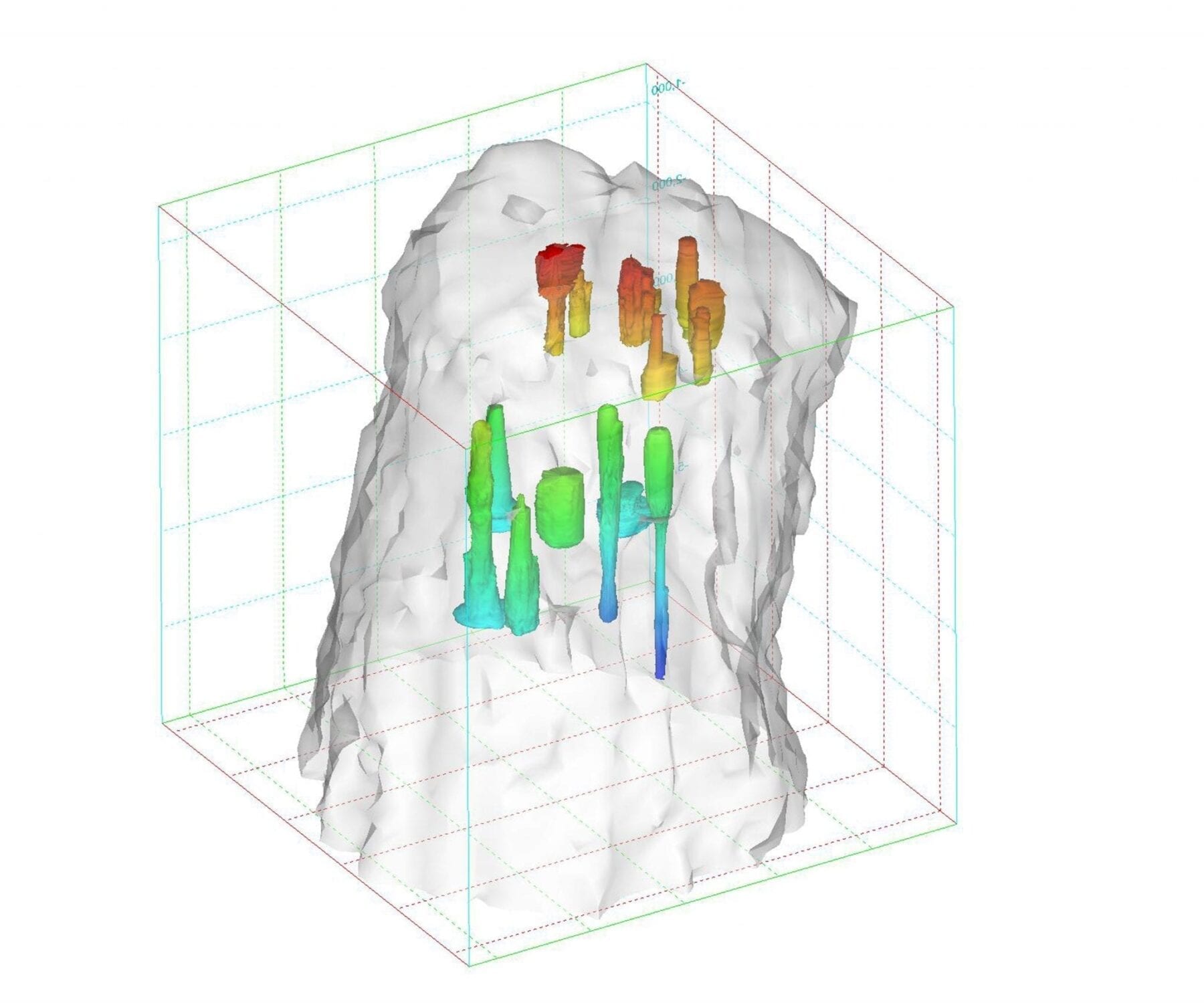

Ekrem is a technical cyberneticist with a doctoral degree in machine vision, and has specialised in providing robots with sharp, three-dimensional vision – which in this case means eyes for the anatomy of a chicken. “Automating this process is something that no one else in the world has succeeded in doing before. Except us”, says Misimi proudly.

“We at SINTEF are the only specialists in Norway to have focused on solving these kinds of problems for the food industry”, he adds. So far, one of our results is the robot Gribbot, named because of its resemblance to a vulture’s beak (‘gribb’ is the Norwegian for vulture).

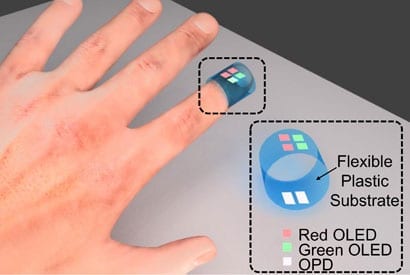

Gribbot is well equipped. It has a hand for grasping, specially developed ‘fingers’, and three-dimensional vision. Its ‘eyes’ have been borrowed from a 3D camera familiar to all games fans – the Microsoft Kinect 2. These are all needed because a chicken fillet is a delicate object that must be handled extremely carefully. The robotic hand must not spoil it with marks or other quality defects. Both the robot’s vision and its grasping hand are critical factors.

Smooth and shiny

“Generally speaking, it’s a major challenge to get a robot to process biological raw materials, because it involves automating a task that is normally performed by skilled people. The raw materials also vary in terms of their size and properties. It’s easy to deform or damage a chicken fillet”, explains Misimi. And because it’s so smooth, a chicken fillet is also an extremely reflective object. That makes it difficult to obtain fully detailed 3D images. The texture also means that the meat is hard to grip. “We realised this early on when we began our research, and were determined to develop a flexible system that could not only tackle variations in the raw materials, but also the mechanical challenges of extracting the fillet from the chicken”, says Misimi.

Mathematical ‘brain surgery’

Naturally, controlling the robot is a key factor.

The Latest on: Robot food processing

[google_news title=”” keyword=”Robot food processing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Robot food processing

- Kraft Heinz's CEO has a clean-eating lifestyle at odds with all that processed food — but he insists it shares his health missionon April 27, 2024 at 5:58 am

Kraft Heinz CEO Carlos Abrams-Rivera practices intermittent fasting and exercises six days a week, The Wall Street Journal reported.

- Chipotle's avocado-cutting robot, Coca-Cola's AI bet, Express' bankruptcy: Retail news roundupon April 26, 2024 at 2:00 am

In the world of retail, American fashion brand Express has filed for bankruptcy and plans to close over 100 stores imminently. Chipotle will deploy its avocado-peeling robots this year. And Coca-Cola ...

- Fizyr Partners with DERO GROEP to Revolutionize Robotic Automation for Advanced Pickingon April 25, 2024 at 10:01 am

The partnership brings highly efficient automation in complex, high-variability tasks to food processing and logistics.

- Dutch agritech innovations may hold answers to Singapore's food security futureon April 25, 2024 at 3:11 am

Food security dilemmas have led to questions on how to grow food safely and efficiently in land-scarce countries like Singapore.

- K-W robotics team shows off 2024 roboton April 25, 2024 at 2:00 am

Wanamingo’s robotics team showed off its latest contraption and shared a bit about its latest work with members of the Kenyon-Wanamingo School ...

- PUDU T300 marks Pudu’s move from service to industrial robotson April 22, 2024 at 6:00 am

Pudu Robotics has designed the PUDU T300 to operate in narrow aisles and to be able to carry up to 300 kg in payload.

- SCARA Robot Market Enigmatic Discoveries Uncharted Territory Techniques Shaping the Future of Researchon April 21, 2024 at 5:08 pm

SCARA Robot Market size was valued at $7.10 billion in 2018, and is projected to reach $14.78 billion by 2026, registering a CAGR of 9.8% from 2019 to 2026. SCARA robot are widely used in food and ...

- How TikTok Changed Uson April 19, 2024 at 3:42 am

TikTok has turned to nuns, veterans and ranchers to argue that it’s a force for good. Israel struck Iran early today, Israeli and Iranian officials said. It appears to be the Israeli military’s first ...

- Vietnam Robot End Effector Market Size, Latest Trends, Share, Key Players, Revenue, Opportunity, and Forecast to 2024 to 2032on April 17, 2024 at 3:25 pm

The recent analysis by Report Ocean on the “Vietnam Robot End Effector Market” Report 2024 to 2032 revolves around various aspects of the market, including characteristics, size and growth, ...

- The best deals at Amazon will save you a bundle on tech, mattresses and moreon April 16, 2024 at 3:54 pm

Whether you're a whiz in the kitchen or a beginner, you've still got to eat. Stop spending so much money on takeout and grab yourself an Instant Pot Pro Plus. You'll feel much better and save money -- ...

via Bing News