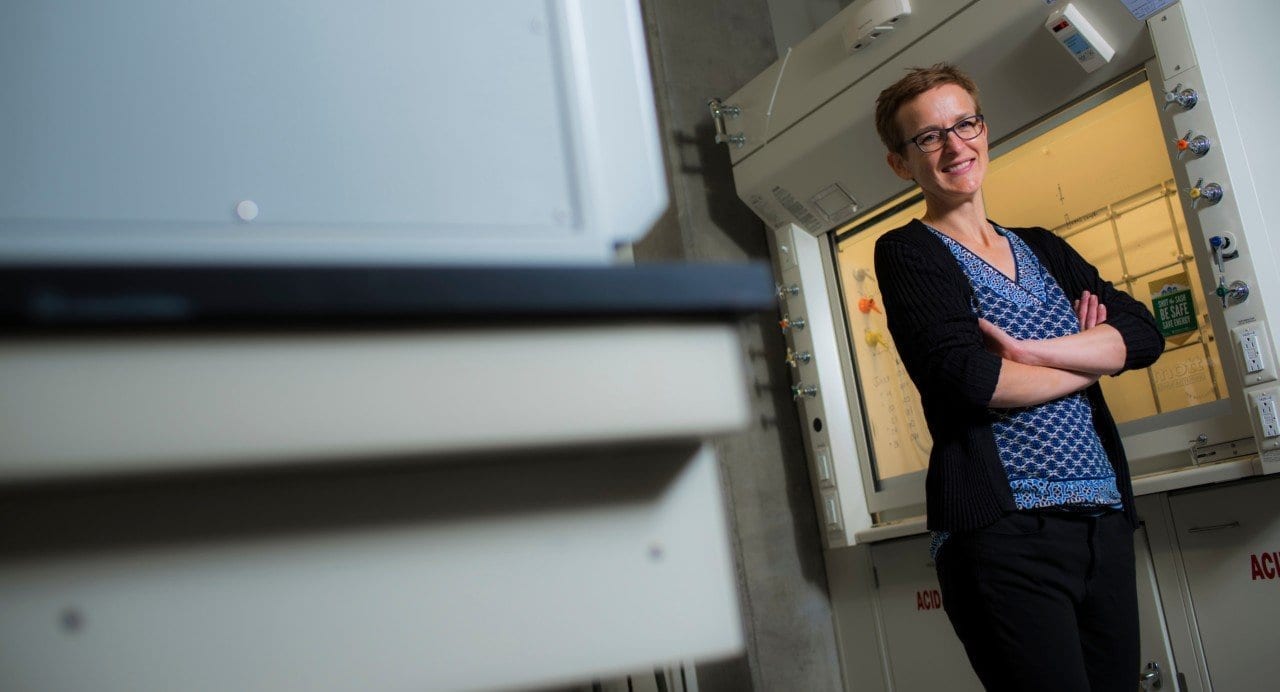

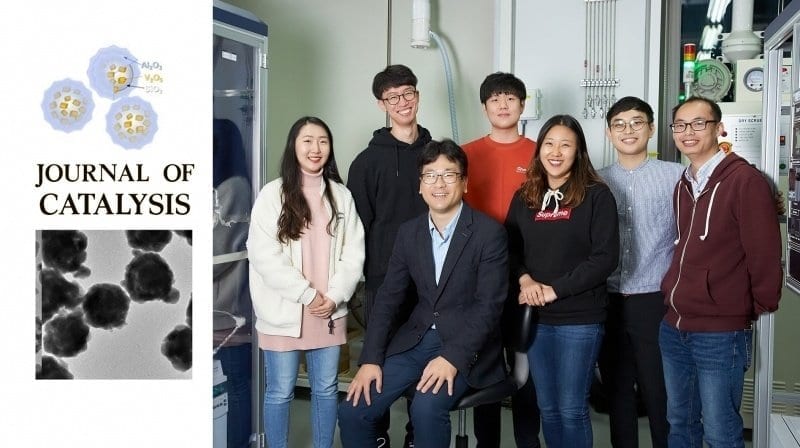

Professor Kwang-jin Ahn (center) and his team in the School of Energy and Chemical Engineering at UNIST. From left are Jihyun Lee, and Dr. Chinh Nguyen-Huy.

The primary component of natural gas, methane, is itself a potent greenhouse gas. A recent study, affiliated with UNIST has unveiled a high performance catalyst for methane conversion to formaldehyde.

This breakthrough has been led by Professor Kwang-jin Ahn and his team in the School of Energy and Chemical Engineering at UNIST in collaboration with Professor Ja Hun Kwak (School of Energy and Chemical Engineering, UNIST), Professor Eun Duck Park from Ajou University, and Professor Yoon Seok Jung from Hanyang University.

In this work, the team has presented an excellent ‘methane oxidase catalyst’ consisting of nanomaterials. This material has a stable structure and high reactivity at high temperatures, increasing the efficiency of converting methane to formaldehyde more than twice as much as before.

Methane, like petroleum, can be converted into useful resources through chemical reactions. The main ingredient of shale gas, which is attracting attention in the US in recent years, is methane, and the technology to make high value-added resources with this material is also recognized as important. The problem is that the chemical structure of methane is so stable that it does not easily react to other substances. So far, methane has been used primarily as fuel for heating and transportation.

A high temperature above 600 ° C is required to effect a reaction that changes the chemical structure of methane. Therefore, a catalyst having a stable structure and maintaining reactivity in this environment is required. Previously, vanadium oxide (V2O2) and molybdenum oxide (MoO3) were known to be the best catalysts. When these catalysts were used, the formaldehyde conversion of methane was less than 10%.

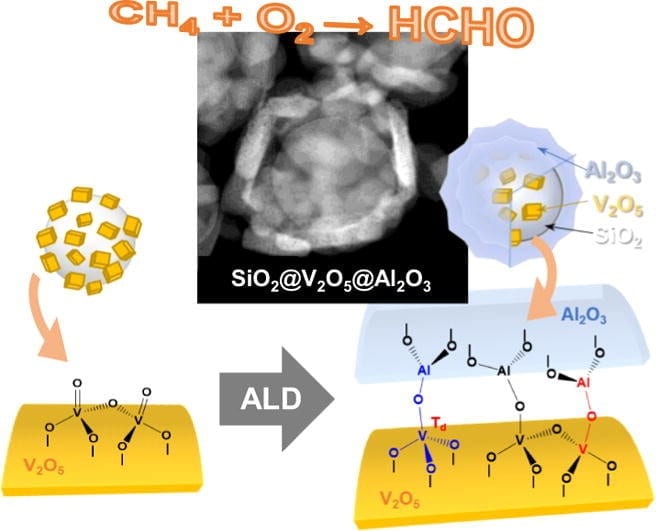

Schematic image showing SiO2@V2O5@Al2O3 core@shell nanostructures.

Professor Ahn made a catalyst that could convert methane to formaldehyde using nanomaterials. Formaldehyde is a useful resource widely used as a raw material for bactericides, preservatives, functional polymers and the like.

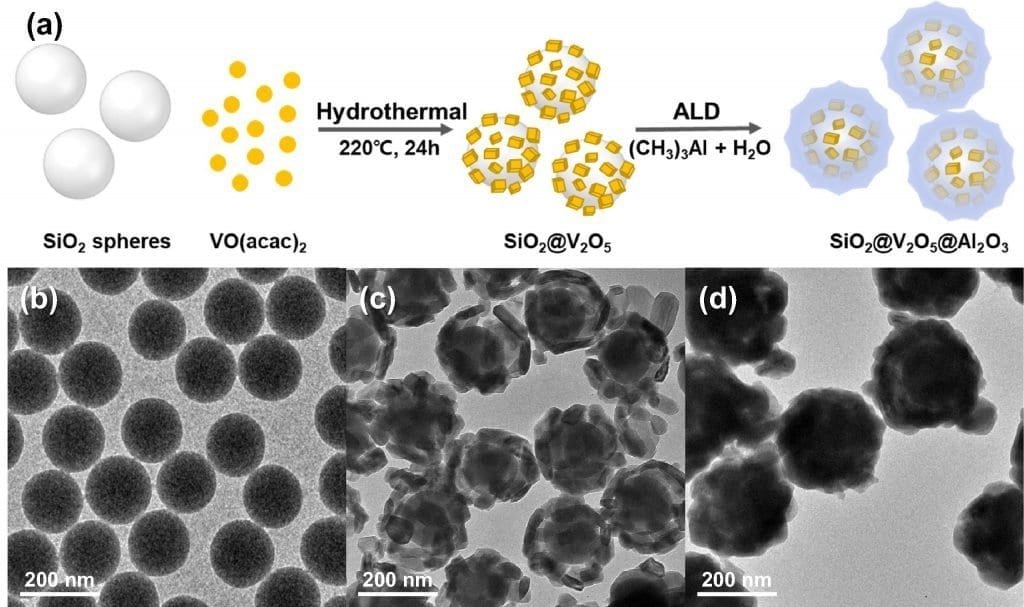

The catalyst has a core-shell structure consisting of vanadium oxide nanoparticles surrounded by a thin aluminum film, with the aluminum shell surrounding the vanadium oxide particles. The shell protects the grain and keeps the catalyst stable and maintains stability and reactivity even at high temperatures.

In fact, when the catalytic reaction was tested with this material, vanadium oxide nanoparticles without aluminum shells had a structural loss at 600 ° C. and lost catalytic activity. However, nanoparticles made from core-shell structures remained stable even at high temperatures. As a result, the efficiency of converting methane to formaldehyde increased by more than 22%. It turned methane into a useful resource with more than twice the efficiency.

“The catalytic vanadium oxide nanoparticles are surrounded by a thin aluminum film, which effectively prevents the agglomeration and structural deformation of the internal particles,” says Euiseob Yang from the Department of Chemical Engineering at UNIST partook as the first author of this study. “Through the new structure of covering the atomic layer with nanoparticles, Thermal stability and reactivity at the same time.”

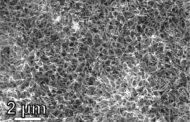

Schematic preparation of SiO2@V2O5@Al2O3 core@shell nanostructures.

This research is particularly noteworthy in terms of improvement in the catalyst field, which has not made great progress in 30 years. The catalytic technology to produce formaldehyde in methane has not made much progress since it was patented in the US in 1987.

“The high-efficiency catalyst technology has been developed beyond the limits of the technology that has remained as a long-lasting technology,” says Professor Ahn. “The value is high as a next-generation energy technology utilizing abundant natural resources.”

He adds, “We plan to expand the catalyst manufacturing technology and catalyst process process so that we can expand our laboratory-level achievements industrially. The catalyst technology has a considerable effect on the chemical industry and contributes to the national chemical industry. I want to develop a practical technology that can do it.”

Learn more: Researchers Find New Ways to Harness Wasted Methane

The Latest on: Waste methane

[google_news title=”” keyword=”waste methane” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Waste methane

- States Challenge Federal Methane Rule, Citing Cost and Interference with Energy Productionon April 26, 2024 at 6:42 pm

At the heart of the legal battle is a rule introduced by the Bureau of Land Management (BLM), designed to minimize methane waste and pollution on federal lands. The regulations set a new precedent by ...

- Wyoming sues Biden Administration over costly and burdensome methane ruleon April 26, 2024 at 12:20 pm

This rule is yet another example of the Biden Administration attempting to use rulemaking to undermine state authority and suffocate the oil and gas industry,” Governor Gordon said.

- Zero Waste Houston will turn your food scraps into compost, reducing greenhouse emissionson April 26, 2024 at 5:03 am

The company picks up customer food scraps weekly, for a low cost starting at $10 a month, and turns it into nutrient-rich soil for local farms and gardens.

- North Dakota sues Bureau of Land Management over new methane rulingon April 25, 2024 at 9:40 pm

The rule establishes a new royalty on flared gas, institutes monthly limits on allowable flaring and adds new application requirements for operators regarding their ability to capture natural gas ...

- US states sue over rule curbing oil and gas methane wasteon April 25, 2024 at 12:51 pm

Four Republican-led states have sued the U.S. Interior Department to block a rule that cracks down on leaks of planet-warming methane during oil and gas drilling on public lands.

- Methane Eating Microbes - A Novel Solution For Greenhouse Gas Mitigationon April 25, 2024 at 7:00 am

Methane is a significant contributor to human-driven greenhouse gas emissions, but there is useful group of microbes that can help because they use methane for food.

- ‘Invisible’ contributor: Methane leaks from landfills are likely worse than previously thoughton April 23, 2024 at 4:16 pm

A new study looking at landfill emissions revealed the industrial waste dumps are likely punching above their weight when it comes to methane leaks. The report, which revealed a significant ...

- To get to zero-waste, hundreds of European cities are spurning incinerationon April 22, 2024 at 5:30 am

In 2010, local authorities in Milan were preparing the ground for the city’s second big incinerator, designed to turn waste into energy and deal with the city’s trash problem at the same time. But a ...

- EPA’s methane rule targeting waste is conservative – good for business and our futures: David Jenkinson April 19, 2024 at 2:57 am

By saving Americans money, boosting our economy, and reducing pollution, the U.S. Environmental Protection Agency's new methane rule represents the exact kind of win-win that genuinely conservative ...

- How waste management innovations are improving landfill sustainabilityon April 17, 2024 at 11:16 am

Innovations in waste management are helping landfills operate more sustainably through investment in technology that converts the methane into renewable natural gas.

via Bing News