The experiment may result in practical applications in electrical conductivity and more.

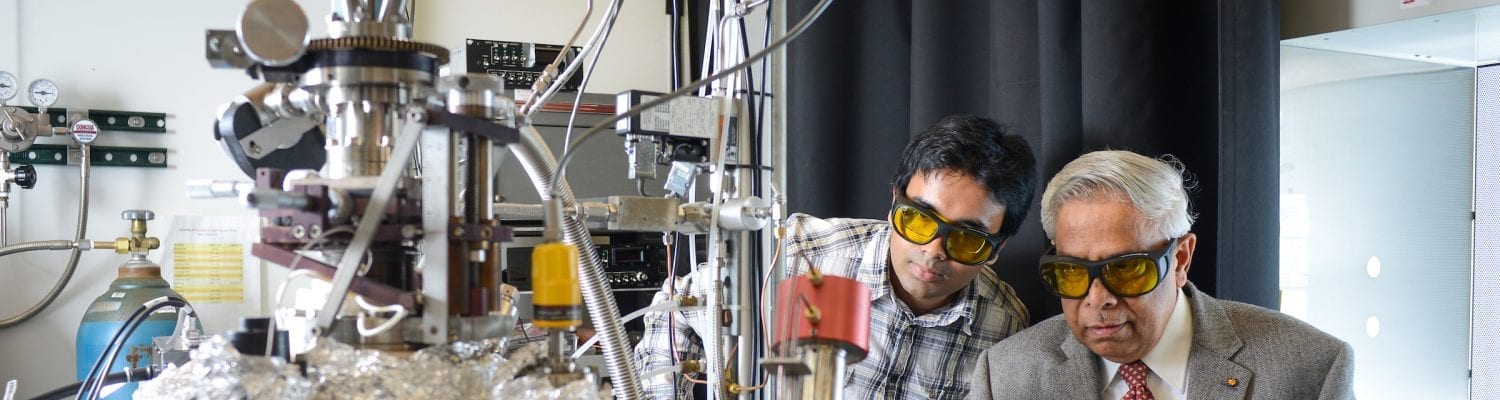

Eden Steven, a physicist at Florida State University’s MagLab facility, discovered that simple methods can result in surprising and environmentally friendly high-tech outcomes during his experiments with spider silk and carbon nanotubes, the results of which are now published in the online research journal Nature Communications.

“If we understand basic science and how nature works, all we need to do is find a way to harness it,” Steven said. “If we can find a smart way to harness it, then we can use it to create a new, cleaner technology.”

Steven is the lead investigator on the paper “Carbon nanotubes on a spider silk scaffold.” The experiment may result in practical applications in electrical conductivity and more.

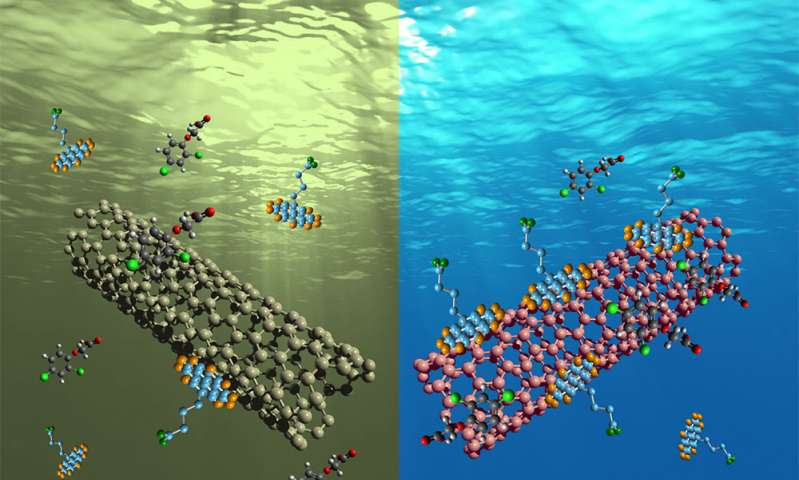

Think of a nanotube as a one-atom thick sheet of carbon that’s been rolled into an infinitesimally tiny tube. A nanotube’s diameter is at least 10,000 times smaller than a strand of human hair. Physicists know that when things get that microscopically minute, they act very strange. Researchers worldwide are intrigued by the properties of carbon nanotubes, including their amazing strength and ability to conduct electricity and heat.

Steven wanted to see what would happen when strands of spider silk were coated with carbon nanotubes. Keeping with his theme of simplicity, he gathered the spider silk himself, hiking around the MagLab and using a stick to gather webs. To adhere the powdery carbon nanotubes to the spider silk, he ultimately discovered that just a drop of water worked best.

The dazzling results have drawn the attention of national media. Steven, now unofficially known as the MagLab’s Spider-Man, has already been interviewed by Discovery News, New Scientist, Materials 360 and The Hindu.

“It turns out that this high-grade, remarkable material has many functions,” Steven said of the silk coated in carbon nanotubes. “It can be used as a humidity sensor, a strain sensor, an actuator (a device that acts as an artificial muscle, for lifting weights and more) and as an electrical wire.”

Rather than add to the already immense amount of toxic elements and complex, non-biodegradable plastics found in today’s electronic devices and as pollution in our environment, Steven wanted to investigate eco-friendly materials. He was especially interested in materials that could deal with humidity without complicated treatments and chemical additives. Spider silk fit the bill.

“Understanding the compatibility between spider silk and conducting materials is essential to advance the use of spider silk in electronic applications,” Steven wrote in the Nature Communications paper. “Spider silk is tough, but becomes soft when exposed to water. … The nanotubes adhere uniformly and bond to the silk fiber surface to produce tough, custom-shaped, flexible and electrically conducting fibers after drying and contraction.”

The Latest on: Spider Silk Coated With Carbon Nanotubes

[google_news title=”” keyword=”Spider Silk Coated With Carbon Nanotubes” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]- Feed has no items.

via Google News and Bing News

The Latest Bing News on:

Spider Silk Coated With Carbon Nanotubes

- Feed has no items.

The Latest Google Headlines on:

Spider Silk Coated With Carbon Nanotubes

[google_news title=”” keyword=”Spider Silk Coated With Carbon Nanotubes” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Spider silk

- Velozzi: Unveiling the Spider Silk-Made Hypercaron April 30, 2024 at 11:49 am

Forget science fiction, because the future of hypercars is here – and it's made from spider silk. The Velozzi is a real American dream machine that uses this incredible material for its strength and ...

- Swimming and spinning aquatic spiders use slick survival strategieson April 28, 2024 at 4:11 am

In another study, researchers investigated the genes used in the silk glands of aquatic and land spiders. They found that water-spider silk seems to have a high proportion of the water-repelling amino ...

- ‘Silk’ Review: Unspooling a Global Commodityon April 26, 2024 at 8:09 am

For thousands of years, moth larvae have been farmed for silk. Industries and economies still rely on the precious fibers.

- Silk, The Ancient Material With High-Tech Possibilitieson April 25, 2024 at 11:47 am

Silk: A World History” describes the unique qualities of silk that make it a sustainable material with a wide variety of applications.

- Qatar Seen As Potential Pioneer In Spider Silk's Biomedical Useon April 7, 2024 at 8:02 pm

Doha, Qatar: The Museum of Islamic Art's (MIA) ongoing“Golden Spider Silk” exhibition has not only captivated visitors but has also sparked potential collaborations with Qatar to advance ...

- Kraig Biocraft Laboratories Shares Industry Update on Recombinant Spider Silk from Waste Plasticson March 28, 2024 at 12:05 am

March 28, 2024 (GLOBE NEWSWIRE) -- Kraig Biocraft Laboratories, Inc. (OTCQB: KBLB) ("Kraig Labs" or "the Company"), comments on an exciting advancement in spider silk engineering from the ...

- Production of spider silk proteins in tobacco and potatoon March 19, 2024 at 5:31 pm

The dragline silk of the spider Nephila clavipes has a high tensile strength that is comparable to that of the synthetic superfiber Kevlar, but it additionally shows high elasticity 1. Such ...

- Scientists Gene-Hack Bacteria to Turn Waste Plastic Into Kevlar-Like Spider Silkon January 27, 2024 at 4:00 am

In a recent study, researchers at Rensselaer Polytechnic Institute were able to gene-hack a strain of bacteria to turn wasteful polyethylene plastic into a spider silk-like material as strong as ...

- Japan spider silk startup snagging major capital for developmenton November 18, 2021 at 11:01 am

TSURUOKA, Yamagata Prefecture--A biotechnology startup based here is drawing major attention from investors for its development of spider silk for use as a synthetic fiber. Spider silk ...

The Latest Google Headlines on:

Spider silk

[google_news title=”” keyword=”spider silk” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]