Not all plastics are created equal. Malleable thermoplastics can be easily melted and reused in products such as food containers. Other plastics, called thermosets, are essentially stuck in their final form because of cross-linking chemical bonds that give them their strength for applications such as golf balls and car tires.

“Nobody takes a thermoset and recycles it like you would a water bottle,” said Orlando Rios from the Department of Energy’s Oak Ridge National Laboratory.

Rios and a team of researchers from Washington State University and the University of Idaho have developed a process to make a thermoset that can be reshaped and reused. The team’s study, published in the journal Macromolecules, is featured on the current issue’s cover.

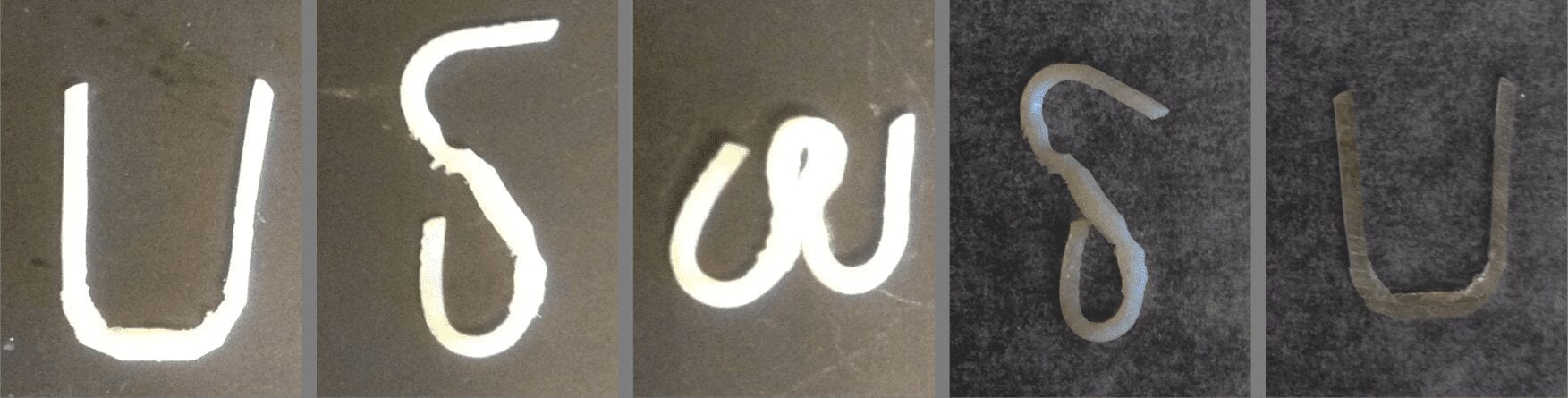

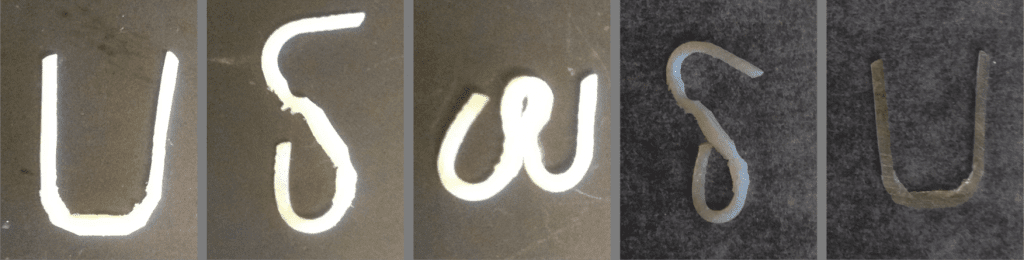

The new plastic is a shape-memory polymer, so named because the material can “remember” its original shape and return to it after being deformed with heat or other forces. The materials exhibit triple-shape memory behavior, meaning that the polymers can transform from one temporary shape to another temporary shape at one temperature, and then back to a permanent shape at another temperature.

Rios explains that although researchers have been interested in making use of shape-memory polymers’ intriguing characteristics, managing the shape-shifting behavior has been a struggle.

“One big issue that has limited their use is controlling the transformation temperatures and their properties,” he said. “We give a recipe where you can adjust the transformation temperature and shift the performance of the material.”

Changing the ratio of ingredients allows the researchers to control the overall properties of the material. The team’s method also uses off-the-shelf chemicals that can be easily scaled up to manufacture the material in bulk.

“We’ve taken it from somewhat of a scientific curiosity or fundamental research material to something that can be produced in larger volumes,” Rios said.

Mixing the shape-memory polymers with other materials could produce stronger and stiffer composite parts that can later be recycled or reprocessed. Recyclable carbon fiber and glass fiber composites, for instance, are in high demand in the automotive industry.

“The ability to control the shape-memory behavior of the material provides great design flexibility,” said Yuzhan Li of Washington State University.

The material could also be used as binding glue for new types of rare earth-free magnets made from powders. The team is already experimenting with 3-D printing powder-based magnets with shape-memory polymers.

“The applications for these materials are very broad, since the shape-shifting temperatures for these materials can be finely tuned by controlling the ratio of the chemicals used in their synthesis,” said Michael Kessler of Washington State University.

Read more: SHAPE-SHIFTING PLASTIC

The Latest on: Shape-shifting plastic

[google_news title=”” keyword=”Shape-shifting plastic” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Shape-shifting plastic

- From bangles to bottles: the changing face of Firozabad’s glass industryon April 28, 2024 at 5:45 am

In Firozabad, glass bangle industry struggles as glassware production rises, impacting traditional artisans and local economy.

- Gazelle Eclipse C380+ HMB review: Pricey but a solid choice for serious commuterson April 27, 2024 at 10:47 am

The Gazelle Eclipse C380+ HMB electric bicycle is on the pricey side, but it's a solid choice for those looking to ditch their automobile.

- Films you can feel: How 4DX went from silly gimmick to the saviour of cinemaon April 26, 2024 at 10:00 am

I am sitting in the 4DX cinema at the O2 in Greenwich, south east London, surrounded by a rig of concealed pistons and flanges. And if you have yet to experience a film in 4DX – “watch” feels like the ...

- The best hearing aids you can buy onlineon April 26, 2024 at 9:58 am

At $397 per pair, this hearing aid is the epitome of quality OTC hearing aids you can buy online: cheap, effective, and with a light design that makes for true all-day comfort. Small, nearly invisible ...

- The Boulevard: Hear Deon Jamar, Marcellus Pittman and moreon April 26, 2024 at 8:50 am

On this week's episode of "The Boulevard," host Waajeed is going deep with new tunes from Deon Jamar, Marcellus Pittman, King Maurice and more.

- Nothing’s Ear A Wireless Earbuds Are Bright, Stylish, and an Unbeatable Valueon April 25, 2024 at 6:30 am

With a new yellow color, a redesigned charging case, ANC, and battery life that rivals the more expensive Ear, Nothing's cheaper $99 Ear A wireless earbuds are an unbeatable value in the tech ...

- Step-by-step guide to moving a piano safelyon April 23, 2024 at 12:26 pm

Our in-depth guide covers how to move your upright or grand piano, including equipment needs, step-by-step instructions and safety tips.

- A global plastics treaty is being negotiated in Ottawa this week—here's the lateston April 23, 2024 at 10:00 am

Plastic pollution spans the globe, yet national policies are generally not effective enough, and have so far focused primarily on waste management rather than targeting the root cause. To make matters ...

- Keep Your Car in Great Shapeon April 17, 2024 at 11:00 pm

Consumer Reports offers advice for where to get your car repaired, and how the right maintenance will save you lots of money.

- Shape-shifting cancer cell discovery reveals potential skin cancer drug targetson April 17, 2024 at 9:36 am

Cancer cells can change shape to travel around the body and spread (metastasize), but how they know when to do this has remained elusive.

via Bing News