The “wonder material” takes an important step toward commercial applications like wearable wireless devices and sensors connected to the “Internet of Things”

Scientists have moved graphene — the incredibly strong and conductive single-atom-thick sheet of carbon — a significant step along the path from lab bench novelty to commercially viable material for new electronic applications.

Researchers from the University of Manchester, together with BGT Materials Limited, a graphene manufacturer in the United Kingdom, have printed a radio frequency antenna using compressed graphene ink. The antenna performed well enough to make it practical for use in radio-frequency identification (RFID) tags and wireless sensors, the researchers said. Even better, the antenna is flexible, environmentally friendly and could be cheaply mass-produced. The researchers present their results in the journal Applied Physics Letters, from AIP Publishing.

The study demonstrates that printable graphene is now ready for commercial use in low-cost radio frequency applications, said Zhirun Hu, a researcher in the School of Electrical and Electronic Engineering at the University of Manchester.

“The point is that graphene is no longer just a scientific wonder. It will bring many new applications to our daily life very soon,” added Kostya S. Novoselov, from the School of Physics and Astronomy at the University of Manchester, who coordinated the project.

Graphene Gets Inked

Since graphene was first isolated and tested in 2004, researchers have striven to make practical use of its amazing electrical and mechanical properties. One of the first commercial products manufactured from graphene was conductive ink, which can be used to print circuits and other electronic components.

Graphene ink is generally low cost and mechanically flexible, advantages it has over other types of conductive ink, such as solutions made from metal nanoparticles.

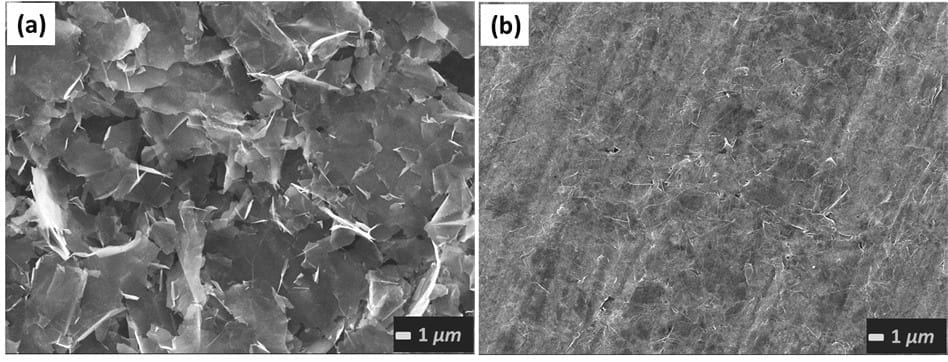

To make the ink, graphene flakes are mixed with a solvent, and sometimes a binder like ethyl cellulose is added to help the ink stick. Graphene ink with binders usually conducts electricity better than binder-free ink, but only after the binder material, which is an insulator, is broken down in a high-heat process called annealing. Annealing, however, limits the surfaces onto which graphene ink can be printed because the high temperatures destroy materials like paper or plastic.

The University of Manchester research team, together with BGT Materials Limited, found a way to increase the conductivity of graphene ink without resorting to a binder. They accomplished this by first printing and drying the ink, and then compressing it with a roller, similar to the way new pavement is compressed with a road roller.

Compressing the ink increased its conductivity by more than 50 times, and the resulting “graphene laminate” was also almost two times more conductive than previous graphene ink made with a binder.

The high conductivity of the compressed ink, which enabled efficient radio frequency radiation, was one of the most exciting aspects of the experiment, Hu said.

Paving the Way to Antennas, Wireless Sensors, and More

The researchers tested their compressed graphene laminate by printing a graphene antenna onto a piece of paper. The antenna measured approximately 14 centimeters long, and 3.5 millimeter across and radiated radio frequency power effectively, said Xianjun Huang, who is the first author of the paper and a PhD candidate in the Microwave and Communcations Group in the School of Electrical and Electronic Engineering.

Printing electronics onto cheap, flexible materials like paper and plastic could mean that wireless technology, like RFID tags that currently transmit identifying info on everything from cattle to car parts, could become even more ubiquitous.

Most commercial RFID tags are made from metals like aluminium and copper, Huang said, expensive materials with complicated fabrication processes that increase the cost.

Read more: Scientists Print Low Cost Radio Frequency Antenna with Graphene Ink

The Latest on: Graphene RFID tags

[google_news title=”” keyword=”Graphene RFID tags” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Graphene RFID tags

- The Walmart RFID Tagging Mandate: Advantages and Compliance Strategieson April 29, 2024 at 9:51 pm

While some retail supply chain leaders may initially feel hesitant about investing in achieving RAIN-tagging compliance, doing so can deliver significant upside potential.

- Tageos Sets Focus on Sustainability and Performance for RFIDon April 26, 2024 at 9:00 am

Tageos showcased new products at RFID Journal Live aimed at a more sustainable solution for companies tracking goods and assets with RFID.

- Conductive Ink Market Is Encouraged to Reach USD 5.6 Billion by 2033 at a CAGR of 6.3%on April 26, 2024 at 2:15 am

According to Market.us, the Conductive Ink Market size is projected to surpass around USD 5.6 billion by 2033, from USD 3.5 billion in 2023, and it is poised to reach a registered CAGR of 6.3% from ...

- FineLine RFID Production Expansion Aims at CPG Companieson April 25, 2024 at 12:00 pm

So in February, FineLine opened an expansion to its O'Fallon site, with an additional 25,000 square feet of space to make it a 50,000 square foot facility. Additionally, the company acquired $2.5 ...

- RFID for Retail: Know the Pros and Conson April 16, 2024 at 5:27 am

Advertising Disclosure RFID (radio frequency identification) has come a long way since the early 2000s. At that time, Walmart was the first big retailer to experiment with the new tracking technology, ...

- How RAIN RFID Works and Benefits Retailerson March 29, 2024 at 10:52 am

Here, Ashley Burkle, business development director of retail solutions at Impinj, explains how RAIN RFID tags work and can be used to track items throughout the supply chain. This can help ...

- Paperless RFID Tags Are Carbon-Basedon October 27, 2023 at 6:58 pm

RFID tags are great little pieces of technology, but unfortunately, the combination of paper, metal, and silicon means they are as bad as some modern pregnancy tests — single-use electronic ...

- Is Graphene Green?on December 25, 2022 at 4:08 pm

As assessed in IDTechEx's latest report, "Graphene Market & 2D Materials Assessment 2023-2033", the capacity for graphene easily exceeds 12,000 tpa. Nearly all of this comes from a graphite feedstock ...

- News tagged with grapheneon January 4, 2017 at 5:24 pm

An international research team led by the University of Göttingen has demonstrated experimentally that electrons in naturally occurring double-layer graphene move like particles without any mass ...

- Graphene proves a perfect fit for wearable deviceson December 17, 2015 at 3:19 am

Examples of communication devices include: • In a hospital, a patient wears a printed graphene RFID tag on his or her arm. The tag, integrated with other 2D materials, can sense the patient’s body ...

via Bing News