Bioprinting technique creates thick 3D tissues composed of human stem cells and embedded vasculature, with potential applications in drug testing and regenerative medicine

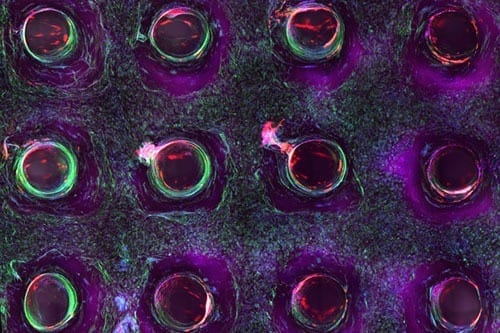

A team at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School for Engineering and Applied Sciences (SEAS) has invented a method for 3D bioprinting thick vascularized tissue constructs composed of human stem cells, extracellular matrix, and circulatory channels lined with endothelial blood vessel cells. The resulting network of vasculature contained within these deep tissues enables fluids, nutrients and cell growth factors to be controllably perfused uniformly throughout the tissue. The advance is reported March 7 in the journal Proceedings of the National Academy of Sciences.

“This latest work extends the capabilities of our multi-material bioprinting platform to thick human tissues, bringing us one step closer to creating architectures for tissue repair and regeneration,” says Wyss Core Faculty member Jennifer A. Lewis, Sc.D., senior author on the study, who is also the Hansörg Wyss Professor of Biologically Inspired Engineering at SEAS.

To date, scaling up human tissues built of a variety of cell types has been limited by a lack of robust methods for embedding life-sustaining vascular networks. Building on their earlier work, Lewis and her team have now increased the tissue thickness threshold by nearly tenfold, setting the stage for future advances in tissue engineering and repair. The method combines vascular plumbing with living cells and an extracellular matrix, enabling the structures to function as living tissues. In the study, Lewis and her team showed that their 3D bioprinted tissues could sustain and function as living tissue architectures for upwards of six weeks.

In the study, Lewis’ team demonstrated the 3D printing of one centimeter-thick tissue containing human bone marrow stem cells surrounded by connective tissue. By pumping bone growth factors through the supporting vasculature lined with the same endothelial cells found in our blood vessels, the team induced cell development toward bone cells over the course of one month.

“This research will help to establish the fundamental scientific understanding required for bioprinting of vascularized living tissues,” Zhijian Pei, National Science Foundation Program Director for the Directorate for Engineering Division of Civil, Mechanical and Manufacturing Innovation, which funded the project. “Research such as this enables broader use of 3-D human tissues for drug safety and toxicity screening and, ultimately, for tissue repair and regeneration.”

Learn more: Scaling up tissue engineering

The Latest on: Bioprinting

[google_news title=”” keyword=”bioprinting” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Bioprinting

- New technique bioprints live cells inside the body using ultrasonic waveson May 8, 2024 at 10:36 pm

Revolutionary acousto-printing method can be used to circumvent invasive surgery, and has a wide array of potential applications.

- 3D printing and bioprinting in healthcare - statistics and factson April 10, 2024 at 5:00 pm

Bioprinting is a much newer technology compared to 3D printing and uses bioinks and other biomaterials to create organ-like structures. Some have referred to bioprinting as ‘healthcare’s next ...

- Advancing gastric cancer treatment through personalized 3D bioprintingon March 21, 2024 at 10:37 am

By using 3D bioprinting to accurately replicate the biological environment surrounding gastric cancer cells, the researchers have achieved a significant feat—predicting a patient's response to ...

- Bioprinting News and Researchon March 17, 2024 at 5:00 pm

FluidForm Bio, a leader in developing life-like human tissue to treat disease, shares recent advancements in building human cardiac tissues using FRESH™ 3D bioprinting. FluidForm Bio ...

- TissueFab® bioink Conductive for 3D bioprintingon November 22, 2023 at 11:00 pm

TissueFab ® bioink Conductive Vis/405 nm, low endotoxin, is a bioink tailored for 3D bioprinting with electrical conductivity. This specialized bioink is designed to create optimal conditions for ...

- Revolutionising osteoarthritis treatment through bioprintingon September 25, 2023 at 7:40 am

In collaboration with clinicians and cell biologists and using the unique capability of The University of Manchester’s Bioprinting Platform, Dr Marco Domingos is developing new technology-driven ...

- 26 Million New Cases, Three Dimensions, And One New Technology: How Bioprinting Can Improve Cancer Treatmentson July 11, 2023 at 3:30 pm

printed from a model (such as the gold bracelet model seen on the laptop screen). Bioprinting, also known as 3D bioprinting, uses cells, growth factors (naturally occurring substances that help ...

- Will 'Bioprinting' Body Parts Lead To Crazy Cosmetic Requests?on July 19, 2022 at 5:00 pm

Please confirm that you would like to log out of Medscape. If you log out, you will be required to enter your username and password the next time you visit. Log out ...

- How bioprinting workson May 8, 2011 at 5:00 pm

The first bioprinters were jury-rigged desktop inkjet printers. Now, some labs use machines, made specifically for bioprinting, that cost up to $300,000. Cornell labs make multipurpose 3-D ...

via Bing News