Tera-Barrier Films invents alternative stretchable plastic for prolonging shelf-life of pharmaceuticals, food and electronics

1. Tera-Barrier Films (TBF) Pte Ltd, a spin-off company from A*A*STAR’s Institute of Materials Research and Engineering’s (IMRE), has invented a new plastic film using a revolutionary nano-inspired process that makes the material thinner but as effective as aluminium foil in keeping air and moisture at bay. The stretchable plastic could be an alternative for prolonging shelf-life of pharmaceuticals, food and electronics, bridging the gap of aluminium foil and transparent oxide films.

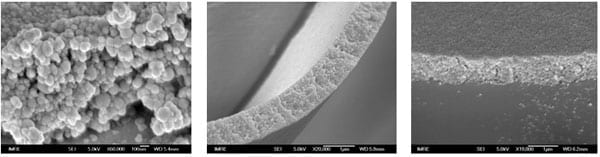

2. The new plastic by TBF has one of the lowest moisture vapour transmission rates (mvtr), preventing air and moisture from penetrating the layer. The plastic has an air and moisture barrier that is about 10 times better than the transparent oxide barriers which are currently being used to package food and medicines owing to its uniquely encapsulated nanoparticle layer. The film has been validated by a number of companies and potential commercialisation partners.

3. TBF’s 700nm encapsulated nanoparticle barrier films – which are thinner than a strand of human hair – have high transparency and are also stretchable, features not possible with aluminium-based packaging material. Inorganic barrier thin films are highly transparent but have lower barrier property and are not stretchable. TBF’s films will allow see-through packing and a longer shelf-life for a wide range of products from high-end electronics to perishable goods. Stretchability is another attractive feature in facilitating simple packaging processes.

4. Aluminium as a metal has very high oxygen and moisture barrier properties, but aluminium-based packaging comes at a higher processing cost, is opaque, non-stretchable, and interferes with electronics, making the integration of components like RFID devices difficult. TBF’s new stretchable thin films are cost effective and transparent, with barrier properties comparable to that of aluminium foil.

5. “TBF’s strategy is to bridge the gap between aluminium foil and transparent oxide films by creating new packaging structures for the niche applications in the food, medical, pharmaceuticals and electronics markets,” said Mr Senthil Ramadas, Director & Chief Technology Officer of TBF. “The secret behind TBF’s film lies in our patented encapsulated nanoparticle layer that consists of nanoparticles in polymer shells”.

6. Conventional multilayer barrier plastics have successive layers of barrier plastic films to enhance the impermeability to air and moisture but they have not achieved higher barrier properties. TBF’s film uses minimal layers as its encapsulated nanoparticles increase the packing density of nanoparticles, which in turn makes it extremely difficult for water and oxygen molecules to pass through the film. The encapsulated nanoparticles also actively adsorb and react with water and oxygen molecules to trap them, thus further lowering the amount of moisture and air passing through the film.

7. “The innovation creates a whole new generation of packaging materials that add new and superior functions for use in high value products such as medicine”, says Professor Andy Hor, Executive Director of A*STAR’s IMRE from where the unique barrier film technology was initially developed, incubated and spun-off. “We are glad to see our scientist-entrepreneurs advancing an IMRE-born technology and are looking forward to seeing it make an impact in the market”.

8. “The University of Tokyo confirmed TBF’s barrier film performance at 10-6g/m2/day”, said Mr. Nakazawa, Managing Director, KISCO (Asia) Pte. Ltd. “There has been very favourable response from our potential customers in a spectrum of industries wishing to benefit by incorporating TBF’s superior barrier films into their products, these applications range from food and medical packaging to high end PV, lighting and display sectors where TBF’s barrier films excel.”

The Latest on: Encapsulated nanoparticle barrier films

[google_news title=”” keyword=”encapsulated nanoparticle barrier films” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Encapsulated nanoparticle barrier films

- Nanotechnology in packaging: enhancing barrier properties and shelf lifeon April 29, 2024 at 4:29 am

Nanotechnology is revolutionising packaging materials, safeguarding products from spoilage and degradation while extending shelf life.

- Stem Cells Newson April 27, 2024 at 5:00 pm

using mRNA technology encapsulated into nanoparticles (LNP) that was successfully used to produce the COVID-19 vaccines, may boost ... Novel and Promising Pancreatic Cancer Organoids for Effective ...

- Nanoparticles Deliver Drugs Directly Across the Blood-Brain Barrieron April 21, 2024 at 5:00 pm

Recent studies published in Nature Communications by an international team of scientists from Michigan State University showed that nanoparticles can traverse ... the green light to pass the ...

- Coveris invests at its extrusion site in Winsford, UKon April 8, 2024 at 9:32 am

Sustainable packaging solution provider Coveris has announced an expansion of its barrier films capabilities with an investment in vacuum skin packaging (VSP) production. This development is ...

- Targeting Liposomes Toward Novel Pediatric Anticancer Therapeuticson April 4, 2024 at 5:00 pm

efficiency and ability to actively load a liposomal nanoparticle depends on the individual chemotherapeutic drug characteristics and reaction conditions. In Mel Brooks' ground breaking film ...

- High oxygen barrier film reduces wastage in silage clampon June 11, 2023 at 4:30 am

A simple switch from multiple sheets of traditional black plastic to a single sheet high oxygen barrier (HOB) silage film could cut silage waste from 15% to 5%. That is the good news story from Tim ...

- The Barrieron May 19, 2023 at 12:25 am

Norman Kerry (Meade Burrell)Henry B. Walthall (Gale Gaylord)Lionel Barrymore (Stark Bennett)Marceline Day (Necia)George Cooper (Sgt. Murphy)Bert Woodruff (No Creek Lee)Neola May (Alluna)Mario ...

- The Barrieron May 7, 2023 at 8:50 pm

Bassam Al-Thawadi Al-Hajiz (The Barrier), the movie deals with social and emotional barriers imposed upon individuals by society and also with those that the individual imposes upon himself.

- Nanoparticle Film Exhibits Wide Applicabilityon March 31, 2022 at 4:59 pm

Previous research has used magnetron sputtering and electrodeposition to create a bismuth-containing seed layer for hydrothermal in-situ growth of bismuth-based photocatalytic films on various ...

- Gas and Vapor Barriers Informationon February 11, 2018 at 6:06 am

Materials packaging is another industry that makes extensive use of gas and vapor barriers in the form of laminated vapor barrier films. The flexibility and durability of these barriers help keep food ...

via Bing News