JBEI Researchers Develop First High-Gravity One-Pot process for Producing Cellulosic Ethanol

The falling price of gasoline at the pumps may warm the hearts of consumers but it chills the souls of scientists who recognize that humankind must curtail the burning of fossil fuels to reduce the threat of climate change. Biofuels can help mitigate climate change and provide us with a sustainable source of transportation energy if yields and production costs are economically competitive. A major step towards achieving this goal has been achieved by researchers with the U.S. Department of Energy (DOE)’s Joint BioEnergy Institute (JBEI).

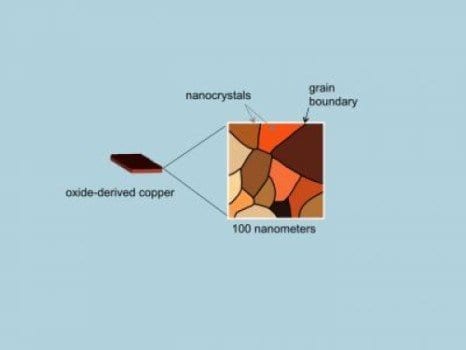

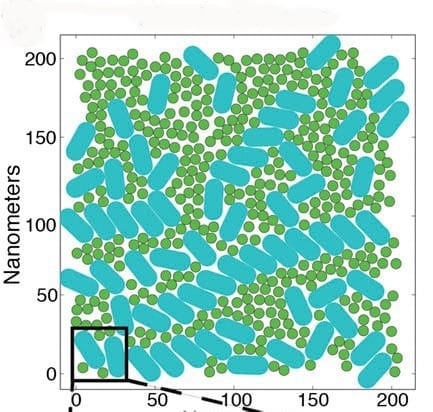

Led by Seema Singh and Blake Simmons, JBEI researchers have developed a “high-gravity” one-pot process for producing ethanol from cellulosic biomass that gives unprecedented yields while minimizing water use and waste disposal. The process utilizes a combination of ionic liquid pretreatment, enzymatic saccharification, and yeast fermentation for the production of concentrated fermentable sugars that result in high-titer cellulosic ethanol. “High gravity” means high biomass loading – the higher the biomass loading, the lower the costs for converting it to fuels.

“Our new one-pot process for making cellulosic ethanol was enabled by the discovery and use of a renewable ionic liquid derived from amino acids that commercially available enzyme mixtures and organisms can tolerate,” says Simmons, a chemical engineer who is JBEI’s Chief Science and Technology Officer and heads the institute’s Deconstruction Division. “This eliminates the need for separations, recoveries and other operational steps, generating significant cost savings.”

Ionic liquids are powerful solvents that can be used to deconstruct (dissolve) cellulosic biomass into sugars for the production of fuels. The renewable ionic liquid to which Simmons refers is one made from lignin and hemicellulose, two by-products of biofuel production from biorefineries. The discovery of the unique properties of this “bionic” liquid was also led by Singh and Simmons.

“Using bionic liquids in our new one-pot high-gravity process we were able to increase biomass digestibility and obtain ethanol titer yields of 41.1 grams/liter, which exceeds the production distillation required for industrial ethanol production,” says Singh, who directs JBEI’s biomass pretreatment program. “The reduction in water consumption combined with the improved overall process economics moves us closer to more affordable and sustainable second-generation biofuels.”

Details on this one-pot process for producing ethanol from cellulosic biomass have been reported in Energy and Environmental Science. The paper is titled “Transforming biomass conversion with ionic liquids: process intensification and the development of a high-gravity, one-pot process for the production of cellulosic ethanol.” In addition to Simmons and Singh, who is the corresponding author, other co-authors are Feng Xu, Jian Sun, Suryanarayana Konda, Jian Shi, Tanmoy Dutta and Corinne Scown.

2015 was the hottest year on record for global average temperature, and marked the 19th straight year that average temperatures in the United States surpassed the average temperatures for the 20th century. The El Niño weather phenomenon is expected to make 2016 even hotter. A major contributor to this alarming trend is the burning of fossil fuels which continues to release nearly 9 billion metric tons of excess carbon into the atmosphere each year. With more than a billion tons of biomass produced annually in the United States alone, biofuels made from the cellulosic sugars in biomass have the potential to substantially reduce the use of fossil fuels.

Simmons and Singh believe that their one-pot process for producing cellulosic ethanol could also be applied to next generation or “advanced” biofuels, those that can be directly “dropped” into today’s gasoline engines and infrastructure. They are currently working with researchers in JBEI’s Fuels Synthesis Division to develop a microbial host capable of producing these advanced biofuels.

“While there is no other ionic liquid system on the planet right now that performs as effectively as ours, we still need to improve on increasing yields and developing a microbial organism that can consume all of the sugars present in the biomass,” Simmons says. “Then we need to develop a host microbe that can generate advanced drop-in biofuels in addition to ethanol.”

Read more: One-Stop Shop for Biofuels

The Latest on: Cellulosic Ethanol

[google_news title=”” keyword=”Cellulosic Ethanol” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Cellulosic Ethanol

- PAMSA announces SA-first solution to convert organic waste into bioethanolon April 26, 2024 at 6:59 am

The Paper Manufacturers Association of South Africa (PAMSA), in collaboration with Stellenbosch University (SU), Sappi Southern Africa and Mpact, has announced a solution that converts paper sludge, ...

- Chemical Warehousing Market to Witness a Significant Jump in Valuation to Reach USD 47.2 Billion: Astute Analyticaon April 24, 2024 at 9:30 am

Sustained by surging chemical production, e-commerce growth, and stricter regulations, the global chemical warehousing market is thriving. Third-party logistics are playing a major role, with Asia ...

- Comstock Inc.: Comstock Completes RenFuel Investmenton April 24, 2024 at 6:23 am

Comstock Inc. (NYSE: LODE) ("Comstock" and the "Company") today announced the execution of agreements with RenFuel K2B AB ("RenFuel") wherein Comstock ...

- Comstock Completes RenFuel Investmenton April 23, 2024 at 11:00 pm

Best-in-Class Yield and Carbon Intensity Comstock’s proprietary technologies are proven to convert lignocellulosic biomass into Cellulosic Ethanol and proprietary Bioleum biointermediate blends at ...

- What is Flex Fuel, and what do E10, E15 and E85 mean?on April 23, 2024 at 6:00 am

On the surface, Flex Fuel sounds like a great idea. Certain cars that are designed for it can run on a variety of blends of gasoline and ethanol. OK, we all know gasoline, but what is ethanol then? It ...

- What is Flex Fuel? The pros and cons of flexible fuel vehicleson April 23, 2024 at 2:00 am

On the surface, Flex Fuel sounds like a great idea. Certain cars that are designed for it can run on a variety of blends of gasoline and ethanol. OK, we all know gasoline, but what is ethanol then? It ...

- Renewable natural gas a new market for damaged grainon April 18, 2024 at 6:53 pm

Renewable natural gas is among the newest low- or no-carbon fuels made from agricultural products that are generating attention from power utilities, ...

- Piper Sandler Keeps Their Sell Rating on Aemetis (AMTX)on April 18, 2024 at 4:18 am

In a report released today, Ryan Todd from Piper Sandler maintained a Sell rating on Aemetis (AMTX – Research Report), with a price ...

- Brazil Readies Ethanol for Green Jet Fuel, Rocking US Rivalson April 16, 2024 at 8:22 am

The US made a huge technological leap forward this year with the launch of the world’s first plant that makes sustainable jet fuel from ethanol — but it’s Brazilian farmers, not American ones, who’ll ...

- Blue Biofuels Initiates Engineering and Design for Their CTS Commercial Plant Positioned to Produce Ethanol from Cellulosic Materialson April 16, 2024 at 5:00 am

In a recent development, Blue Biofuels Inc. (“BIOF”) proudly announces the commencement of an FEL 1 & 2 engineering study for a 2.4-million-gallon cellulosic ethanol facility. This endeavor is ...

via Bing News