Pretty soon, powering your tablet could be as simple as wrapping it in cling wrap.

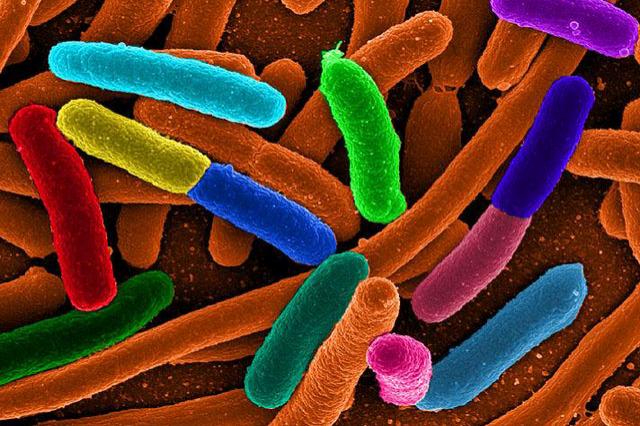

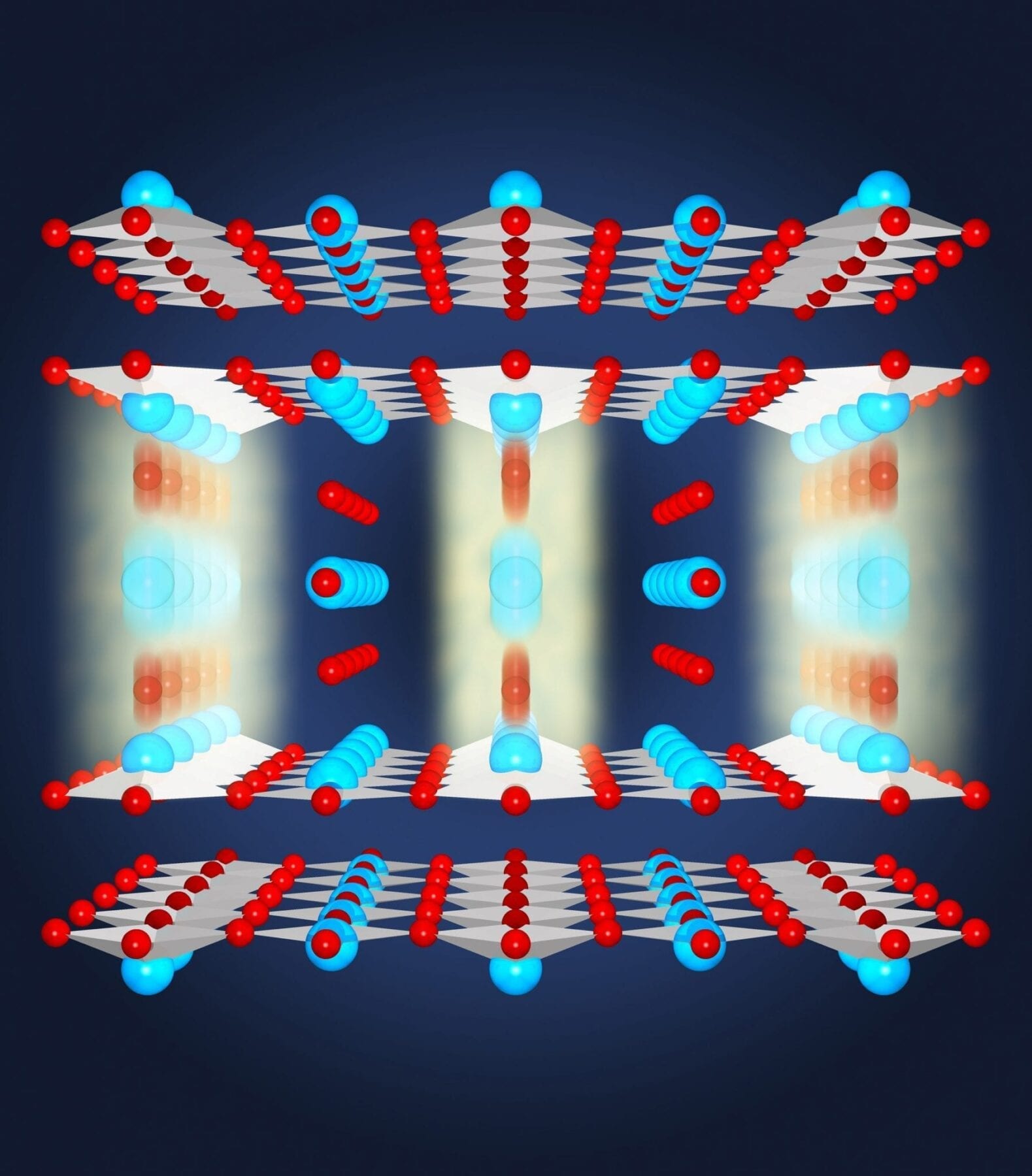

That’s Illan Kramer’s (ECE) hope. Kramer and colleagues have just invented a new way to spray solar cells onto flexible surfaces using miniscule light-sensitive materials known as colloidal quantum dots (CQDs)—a major step toward making spray-on solar cells easy and cheap to manufacture.

“My dream is that one day you’ll have two technicians with Ghostbusters backpacks come to your house and spray your roof,” said Kramer, a post-doctoral fellow with The Edward S. Rogers Sr. Department of Electrical & Computer Engineering at the University of Toronto and IBM Canada’s Research and Development Centre.

Solar-sensitive CQDs printed onto a flexible film could be used to coat all kinds of weirdly shaped surfaces, from patio furniture to an airplane’s wing. A surface the size of your car’s roof wrapped with CQD-coated film would produce enough energy to power three 100-Watt light bulbs—or 24 compact fluorescents.

He calls his system sprayLD, a play on the manufacturing process called ALD, short for atomic layer deposition, in which materials are laid down on a surface one atom-thickness at a time.

Until now, it was only possible to incorporate light-sensitive CQDs onto surfaces through batch processing—an inefficient, slow and expensive assembly-line approach to chemical coating. SprayLD blasts a liquid containing CQDs directly onto flexible surfaces, such as film or plastic, like printing a newspaper by applying ink onto a roll of paper. This roll-to-roll coating method makes incorporating solar cells into existing manufacturing processes much simpler. In two recent papers in the journals Advanced Materials and Applied Physics Letters, Kramer showed that the sprayLD method can be used on flexible materials without any major loss in solar-cell efficiency.

Kramer built his sprayLD device using parts that are readily available and rather affordable—he sourced a spray nozzle used in steel mills to cool steel with a fine mist of water, and a few regular air brushes from an art store.

The Latest on: Spray-on solar power

[google_news title=”” keyword=”Spray-on solar power” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Spray-on solar power

- Native American News Roundup, April 21-27, 2024on April 27, 2024 at 12:25 pm

Oklahoma Representative Tom Cole listens during a House Committee on Appropriations, Subcommittee on Defense budget hearing on Capitol Hill in Washington, April 17, 2024. Oklahoma congressman Tom Cole ...

- Solinftec Launches Agricultural Spraying Robot Robotics & Automation Newson April 27, 2024 at 2:48 am

Solinftec , a global leader in artificial intelligence solutions and sustainable agricultural practices, has announced that its Solix Sprayer Robot i ...

- The best Amazon deals to shop this weekend: Save up to 80% on early Mother's Day gifts, tech gadgets, gardening essentials and moreon April 26, 2024 at 1:14 pm

Check out our roundup of the best air purifiers for more.

- Revolutionizing Roofs Exploring Pennsylvania’s Innovative Roofing Trends and Techniqueson April 25, 2024 at 7:38 pm

One of the most unique trends in Pennsylvania roofing is the use of green roofs. Green roofs involve covering a roof with vegetation, creating a living, eco-friendly surface. This concept has gained ...

- Vegas luxury embraces green homebuildingon April 23, 2024 at 11:12 am

Net-zero energy homebuilding has been gaining popularity with luxury designers as they push new boundaries to deliver cutting-edge performance homes to their clients.

- 5 ways to make your Philly-area home greeneron April 23, 2024 at 2:52 am

Worried about your carbon footprint, but not sure where to start? Turns out there’s plenty you can do at home.

- Gardening fans are racing to snap up a bargain that will remove stubborn algae from your fence – & there’s no scrubbingon April 21, 2024 at 8:30 am

GREEN-FINGERED Brits have revealed how to tackle green algae and remove it from your fence with no vigorous scrubbing. After a harsh winter of snow, rain and wind, chances are your fence is ...

- How Much Do Solar Panels Cost In 2024?on April 15, 2024 at 11:19 pm

Monocrystalline solar panels cost between $1 and $1.50 per watt ... such as an extension ladder, garden hose spray attachments, squeegees, soft brushes and a one-gallon handheld sprayer, you ...

- Origami Solar steel panel frames pass mechanical load and corrosion testingon April 10, 2024 at 7:10 am

Steel solar panel frame manufacturer Origami Solar announced that after months of independent testing at CFV Labs and the Renewable Energy Test Center ...

- 'Solar paint' technology could be cheaper alternative to panels: 'Billions of light-sensitive particles [are] mixed in'on January 10, 2024 at 4:16 am

Solar panels are already an affordable energy solution ... and the University of Toronto has developed a spray-on substance to make what is essentially solar wallpaper — which could lead to ...

via Bing News