Could prove far less expensive than the industry’s current method

A newly synthesized material might provide a dramatically improved method for separating the highest-octane components of gasoline. Measurements at the National Institute of Standards and Technology (NIST) have clarified why. The research team, which included scientists from NIST and several other universities, has published its findings in the journal Science.*

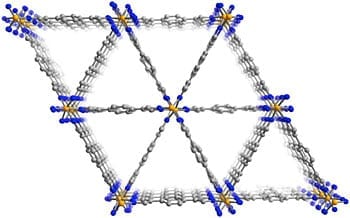

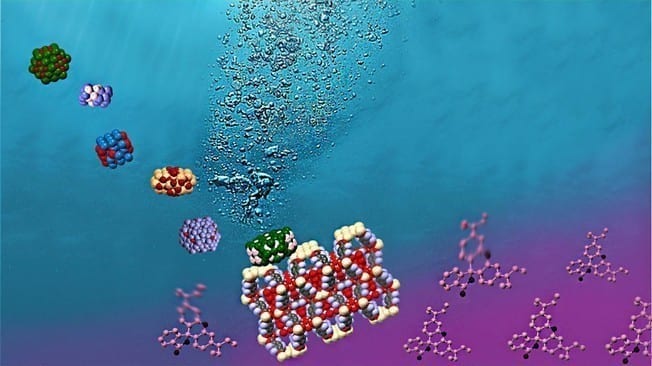

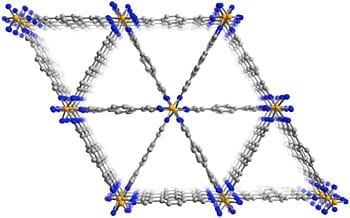

Created in the laboratory of Jeffrey Long, professor of chemistry at the University of California, Berkeley, the material is a metal-organic framework, or MOF, which can be imagined as a sponge with microscopic holes. The innumerable interior walls of the MOF form triangular channels that selectively trap only the lower-octane components based on their shape, separating them easily from the higher-octane molecules in a way that could prove far less expensive than the industry’s current method. The Long laboratory and UC Berkeley have applied for a patent on the MOF, which is known by its chemical formula, Fe2(bdp)3.

High-octane gasolines, the ultra or premium blends at fueling stations, are more expensive than regular unleaded gasoline due to the difficulty of separating out the right type of molecules from petroleum. Petroleum includes several slightly different versions of the same molecule that have identical molecular formulae but varying shapes—called isomers. Creating premium fuel requires a refinery to boil the mixture at precise temperatures to separate the isomers with the most chemical energy. The trouble is, four of these isomers—two of which are high octane, the other two far lower—have only slightly different boiling points, making the overall process both challenging and costly.

The new MOF, however, could allow refineries to sidestep this problem by essentially trapping the lowest-octane isomers while letting the others pass through. The lowest-octane isomers are more linear and can nestle closer to the MOF walls, so when a mixture of isomers passes through the MOF, the less desired isomers stick to its surface—somewhat akin to the way a wet piece of paper sticks to a wall.

The Latest Bing News on:

Petroleum Refining

- Why Nigeria may not benefit from local refining of crude oil- NESGon May 9, 2024 at 9:16 am

The Nigerian Economic Summit Group (NESG) has stated that unless certain conditions are met, Nigeria may not reap the benefits ...

- Star Petroleum Refining PCLon May 5, 2024 at 5:00 pm

We sell different types of products and services to both investment professionals and individual investors. These products and services are usually sold through license agreements or subscriptions ...

- Company History - Reliance Petroleumon May 5, 2024 at 5:00 pm

The Company formed to set up a greenfield petroleum refinery and polypropylene plant to be located in a Special Economic Zone in Jamnagar in the state of Gujarat in western India. The proposed ...

- Star Petroleum Refining PCL SPRCon May 3, 2024 at 2:38 am

Morningstar Quantitative Ratings for Stocks are generated using an algorithm that compares companies that are not under analyst coverage to peer companies that do receive analyst-driven ratings ...

- Roundup: U.S. crude supplies down, other petroleum data mixedon May 1, 2024 at 5:00 pm

HOUSTON, May 1 (Xinhua) -- U.S. crude oil refinery inputs averaged 15.6 million barrels per day (b/d) during the week ending April 26, 230,000 b/d less than the previous week's average ...

- Dangote refinery ramps up production with US crude – Reporton April 18, 2024 at 5:00 pm

The 650,000 barrels per day Dangote Petroleum Refinery is taking advantage of cheaper oil imports from the United States for as much as a third of its feedstock as it starts up production.

- Oil consumption back to 2019 levelson April 17, 2024 at 2:12 am

China's petroleum refining capacity is entering a new expansion phase with 85 million metric tons expected to be added from 2024 to 2027, experts said. Around 35 million tons of outdated petroleum ...

- Dangote refinery announces reduction in price of dieselon April 16, 2024 at 5:01 pm

“In an unprecedented move, Dangote Petroleum Refinery has announced a further reduction of the price of diesel from 1200 to 1,000 naira per litre. “While rolling out the products, the refinery ...

- NUPRC Bars Producers Not Meeting Domestic Crude Supply Obligation From Exporton April 16, 2024 at 2:33 am

Crude Oil Refinery-Owners Association of Nigeria (CORAN), and Dangote Petroleum Refinery, and aims to streamline the supply of crude oil to domestic refineries and enhance the sustainability of ...

- Marathon Petroleum CEO Hennigan to remain on job during cancer treatmenton April 10, 2024 at 5:00 pm

Marathon operates 13 refineries with a combined crude oil refining capacity of 2.9 million barrels per day (bpd), equal to 16% of total U.S. processing, according the U.S. Energy Information ...

The Latest Google Headlines on:

Petroleum Refining

[google_news title=”” keyword=”Petroleum Refining” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Metal-organic framework

- A Stunning New Material May Shrink Humanity’s Carbon Footprinton May 7, 2024 at 4:30 am

Scientists at MIT estimate that humans produce roughly 35 billion tons of CO 2 every year, and that the Earth soaks up about half of it. To help fight against climate change, we need to suck up the ...

- Charging future EVs could take seconds with new sodium-ion battery techon May 3, 2024 at 4:01 am

A new type of hybrid sodium-ion battery that offers both high capacity and rapid-charging capabilities could power mobile devices, electric vehicles and space tech.

- New sugar-based catalyst could offer a potential solution for using captured carbonon May 2, 2024 at 11:00 am

A new catalyst made from an inexpensive, abundant metal and common table sugar has the power to destroy carbon dioxide (CO2) gas.

- When does a conductor not conduct? Switching a 2D metal-organic framework from an insulator to a metalon April 29, 2024 at 7:40 am

An Australian-led study has found unusual insulating behavior in a new atomically-thin material—and the ability to switch it on and off.

- Metal–organic frameworks articles from across Nature Portfolioon April 25, 2024 at 5:00 pm

Metal-organic frameworks (MOFs) are a class of crystalline materials that consist of coordination bonds between transition-metal cations and multidentate organic linkers. The structure of MOFs is ...

- IDTechEx Forecasts Metal-Organic Frameworks Market to Grow to US$685 Million by 2034on April 25, 2024 at 3:17 am

Metal-organic frameworks (MOFs) are a class of materials with exceptionally high porosity and surface area (up to 7000m2/g). The design flexibility and structural versatility afforded by MOFs have ...

- IDTechEx Release New Global Metal-Organic Frameworks Market Reporton April 17, 2024 at 5:00 pm

IDTechEx Research, a trusted provider of independent market intelligence, announces the availability of a new report, "Metal-Organic Frameworks (MOFs) 2024-2034: Market, Technology, and Players".

- Metal-Organic Frameworkson March 25, 2024 at 5:00 pm

Metal-organic frameworks (MOFs), also known as porous coordination polymers, are a group of organic-inorganic hybrid materials that have garnered considerable attention due to their unique ...

- What is a MOF (metal organic framework)?on January 21, 2024 at 11:49 pm

Metal-organic frameworks (MOFs) are organic-inorganic hybrid crystalline porous materials that consist of a regular array of positively charged metal ions surrounded by organic 'linker' molecules. The ...

The Latest Google Headlines on:

Metal-organic framework

[google_news title=”” keyword=”metal-organic framework” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]