Masdar Institute Researchers Leverage 3D Printing to Fabricate Strong, Lightweight Metals and Plastics with Optimized Electrical, Thermal and Mechanical Properties

Researchers from the Masdar Institute have leveraged the unique capabilities of additive manufacturing – or 3-dimensional (3D) printing – to design strong, ultra-lightweight ‘architectured foam’ structures that have the potential to make vehicle bodies much lighter and stronger and improve water production and oil and gas operations.

The novel foams can be 3D printed with various materials such as plastics, metals, ceramics, and composite materials to enhance the thermal, electrical and mechanical properties of various engineering systems, including aerospace and automotive structural components. They can be used anywhere there is a need for very strong, lightweight and conductive materials, such as in the aerospace and defense industries, or they can be used in applications that require highly conductive or porous materials, such as the energy, water and medical industries.

“The foam structures have the potential to become a platform technology, driving innovations across key industries and markets,” said Masdar Institute’s Dr. Steve Griffiths, Vice President for Research. “This project demonstrates how Masdar Institute’s strong advanced materials research capabilities support disruptive technology-based innovations in the Institute’s core research areas of water and energy while benefiting other sectors of importance to the UAE.”

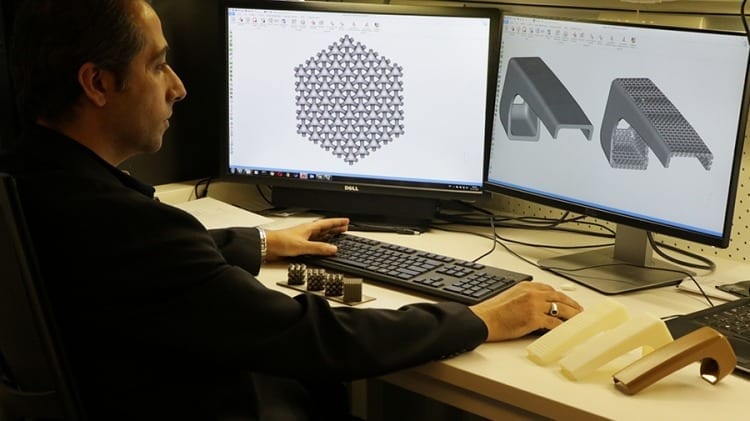

Masdar Institute’s Dr. Rashid Abu Al-Rub, Associate Professor of Mechanical and Materials Engineering, is leading this collaborative research through the development of a computer model that can design thousands of different architectured foams. The research has been featured in over five peer-reviewed journals, including Composites Science and Technology.

“The key to the foams’ strength and light weight is in their internal geometry or what we refer to as internal architecture,” Dr. Abu Al-Rub explained.

Similar to how the Eiffel Tower achieves its strength through a lattice of steel beams and struts balanced against open air, Dr. Abu Al-Rub’s cellular materials – which are more than 90% air – achieve their strength through the airy, geometric arrangements of their internal structure.

“We are not creating new materials. Rather, we are re-architecting a given material, such as steel or plastic, by manipulating its internal geometry so that we can deliver the desired properties – whether stiffness, electrical conductivity, or porosity – to the material,” he added.

The model can generate thousands of foam structures, allowing the researchers to select the desired properties of the foam – such as enhanced thermal and electrical properties, lightweight and stiffness. Once designed in the model, the foams are then fabricated with a 3D printer.

The foams can be used as a three-dimensional continuous reinforcement, enhancing the properties of other solid materials, or they can be used independently as standalone foams.

The researchers are engaging with several companies to secure the proof-of-concept funding needed to accelerate the innovative foam’s commercialization.

One of the properties that can be manipulated and tailored by the computer model is the porosity of a structure in order to control the flow distribution of a gas or liquid, which is an important aspect of oil and gas operations, seawater desalination processes, wastewater treatment systems and catalytic converters.

“The foam structures could be used to maximize gas flow, and increase the conversion efficiency of catalytic converters to reduce greenhouse gas emissions from car engines,” said Oraib Al-Ketan, a PhD student working with Dr. Abu Al-Rub.

As the foams’ architectures are extremely complex, they pose a challenge to traditional manufacturing processes. But thanks to recent technological advances in 3D printing (which creates objects by adding material layer by layer), the complex foams can be printed at extremely small dimensions, such as the nano-scale – a size scale a hundred-thousand times thinner than a human hair – or the macro scale – a size scale measured in millimeters. New York University Abu Dhabi’s Dr. Reza Rowshan, Director of Core Technology Platforms Operation, provided valuable collaboration to improve the performance and manufacturability of the 3D printed metallic foams.

“We have introduced a paradigm shift in how materials are being designed. Currently, people design materials based on a material’s existing chemistry, structure and its corresponding properties. Our vision for material design instead looks first at the desired properties you are targeting in a material for a product application and then applies our proprietary design methods to optimize the structure and its’ internal geometry so that it will give you those desired properties,” Dr. Abu Al-Rub said. As a next step in the development of this promising innovation, Dr. Abu Al-Rub is seeking industry collaborators to explore the applications of his 3D printed architecture foams in a number of key UAE sectors.

The Latest on: Architectured foam

[google_news title=”” keyword=”Architectured foam” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Architectured foam

- Do Gutter Guards Work in Heavy Rain?on April 24, 2024 at 5:00 pm

Foam and reverse-curve gutter guards can overflow if the rain gets too intense while cheap gutter guards may break amid heavy downpours. Read our guide below to find the best gutter guards for you ...

- The Best Memory Foam Mattresses, Chosen By Sleep Expertson April 22, 2024 at 2:17 pm

The best memory foam mattresses relieve pressure and contour to your body, but also curb movement so you can sleep undisturbed. Side sleepers, folks with back pain and couples can all benefit from ...

- Best Gel Mattress for 2024on April 19, 2024 at 12:00 pm

A gel memory foam mattress can be made from swirled gel, poured gel or gel microbeads. Whichever of these gel types you choose, it'll offer the support you need while also helping cool off your ...

- The best memory foam mattress topper in 2024on April 12, 2024 at 11:49 am

The best memory foam mattress topper is a quick and budget-friendly way to add that body-contouring, soothing foam feel to any mattress. An memory foam topper is also useful for softening up a too ...

- How Much Does Spray Foam Insulation Cost? (2024)on April 10, 2024 at 5:00 pm

Here are some tips to save on spray foam insulation, even if you hire a pro. Here’s what to look for when comparing insulation contractors. Installing spray foam requires specialty training ...

- 11 Best Memory Foam Mattresses That'll Support Your Dreams and Your Backon April 9, 2024 at 5:00 pm

Can take up to 3 days for the mattress to reach it's full shape Contains fiberglass, so an extra mattress cover is recommended This four-layer memory foam mattress is great for your sleeping ...

- The best foam rollers in 2024, tried and testedon April 8, 2024 at 5:59 am

While there are tons of overhyped recovery aids, the foam roller is legit; a 2023 review published in Sports found more positive evidence to support this kind of self-myofascial release (AKA self ...

- The 9 Very Best Memory-Foam Pillowson April 5, 2024 at 9:25 am

Memory foam is one of the best materials for those looking for maximum support from their pillow. Originally designed by NASA for aircraft cushions, memory foam is made mostly from a type of plast ...

- The 10 best foam rollers 2024: tested and reviewedon April 4, 2024 at 4:33 am

The best foam rollers are designed to be rolled over sore muscles to lessen post-workout soreness. They're also a hell of a lot cheaper than the best massage guns on the market, so if you're ...

- Amerisleep Mattress Review: Memory Foam Feel With Multiple Firmness Optionson April 3, 2024 at 1:01 pm

If you love memory foam and want a value option, then you'll want to check out Amerisleep. Here are my unbiased thoughts on each mattress in the brand's lineup. McKenzie, a Certified Sleep Science ...

via Bing News