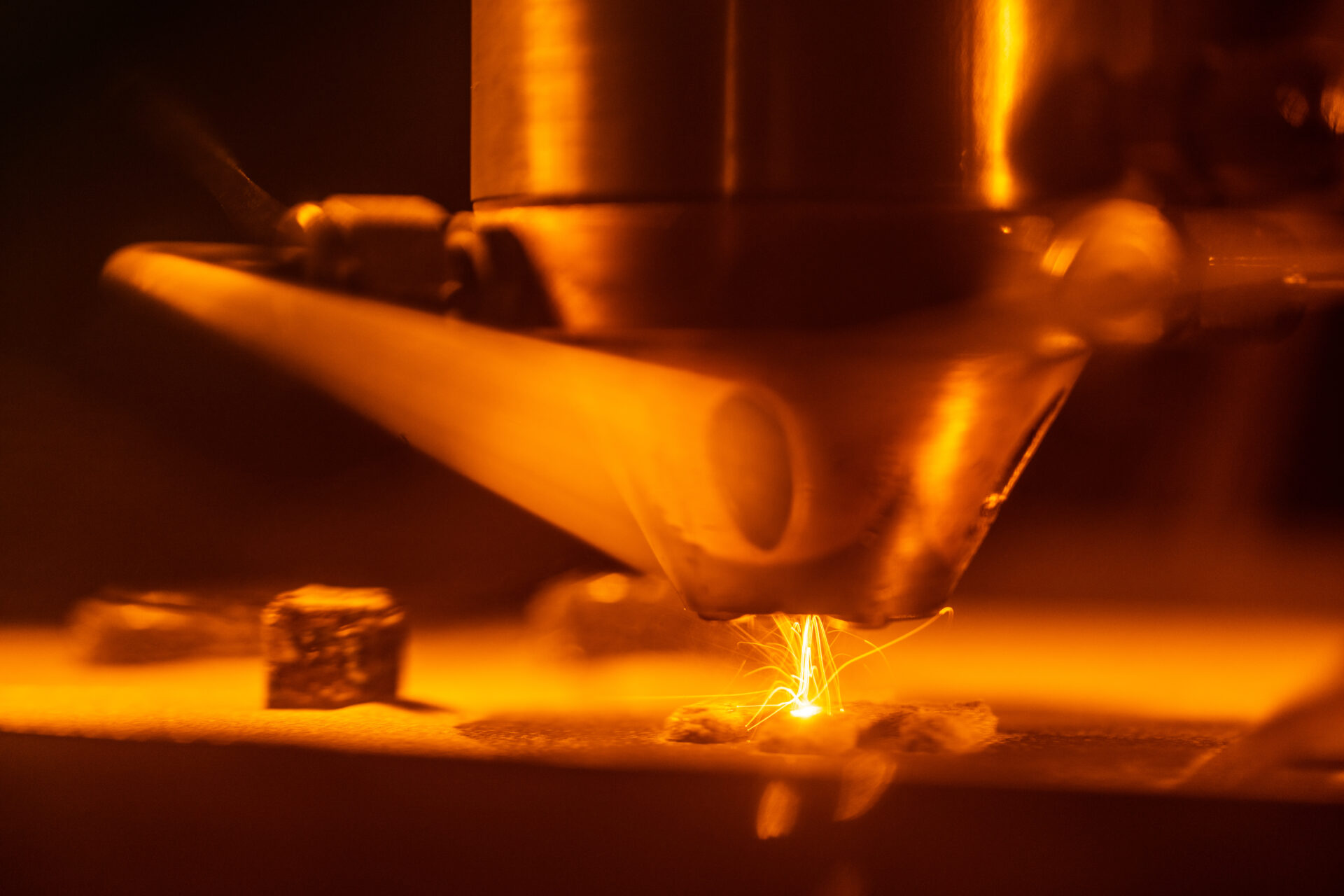

3D-printing technologies like Laser Engineered Net Shaping, shown here, are helping scientists at Sandia National Laboratories rapidly discover, prototype and test new materials.

(Photo by Craig Fritz)

As the world looks for ways to cut greenhouse gas emissions, researchers from Sandia National Laboratories have shown that a new 3D-printed superalloy could help power plants generate more electricity while producing less carbon.

Sandia scientists, collaborating with researchers at Ames National Laboratory, Iowa State University and Bruker Corp., used a 3D printer to create a high-performance metal alloy, or superalloy, with an unusual composition that makes it stronger and lighter than state-of-the-art materials currently used in gas turbine machinery. The findings could have broad impacts across the energy sector as well as the aerospace and automotive industries, and hints at a new class of similar alloys waiting to be discovered.

“We’re showing that this material can access previously unobtainable combinations of high strength, low weight and high-temperature resiliency,” Sandia scientist Andrew Kustas said. “We think part of the reason we achieved this is because of the additive manufacturing approach.”

The team published their findings in the journal Applied Materials Today.

Material withstands high heat, essential for power plant turbines

About 80% of electricity in the U.S. comes from fossil fuel or nuclear power plants, according to the U.S. Energy Information Administration. Both types of facilities rely on heat to turn turbines that generate electricity. Power plant efficiency is limited by how hot metal turbine parts can get. If turbines can operate at higher temperatures, “then more energy can be converted to electricity while reducing the amount of waste heat released to the environment,” said Sal Rodriguez, a Sandia nuclear engineer who did not participate in the research.

Sandia’s experiments showed that the new superalloy — 42% aluminum, 25% titanium, 13% niobium, 8% zirconium, 8% molybdenum and 4% tantalum — was stronger at 800 degrees Celsius (1,472 degrees Fahrenheit) than many other high-performance alloys, including those currently used in turbine parts, and still stronger when it was brought back down to room temperature.

“This is therefore a win-win for more economical energy and for the environment,” Rodriguez said.

Energy is not the only industry that could benefit from the findings. Aerospace researchers seek out lightweight materials that stay strong in high heat. Additionally, Ames Lab scientist Nic Argibay said Ames and Sandia are partnering with industry to explore how alloys like this could be used in the automotive industry.

“Electronic structure theory led by Ames Lab was able to provide an understanding of the atomic origins of these useful properties, and we are now in the process of optimizing this new class of alloys to address manufacturing and scalability challenges,” Argibay said.

Original Article: New superalloy could cut carbon emissions from power plants

More from: Sandia National Laboratories | Ames National Laboratory | Iowa State University

The Latest Updates from Bing News

Go deeper with Bing News on:

3D-printed superalloy

- WWII 'Great Escape' Pilot's Lost Spitfire Set to Fly Again After 83 Years

The aircraft shot down by German planes in 1942 was piloted by an airman who took part in a famous POW camp breakout.

- Makers of the world’s largest 3D printer just beat their own record

After a five-year reign, the world’s largest 3D printer located at the University of Maine has been usurped—by a newer, larger 3D printer developed at the same school.

- The world’s largest 3D printer is at a university in Maine. It just unveiled an even bigger one

The university that boasts the world’s largest 3D printer developed one even bigger. A printer unveiled Tuesday at the University of Maine is four times larger than the current one and is capable of ...

- Best Budget 3D Printer of 2024

traditional paper printers Credentials 6 years working professionally in the 3D printing space / 4 years testing consumer electronics for large websites. CNET’s expert staff reviews and rates ...

- Laser-based sensor promises breakthrough in 3D printing

New laser-based sensing technology has been revealed and could change the quality assessment of critical metallic components ...

Go deeper with Bing News on:

Superalloy

- WWII 'Great Escape' Pilot's Lost Spitfire Set to Fly Again After 83 Years

The aircraft shot down by German planes in 1942 was piloted by an airman who took part in a famous POW camp breakout.

- What Was the NASA Space Trash That Plunked Through a Florida Home Made Of?

A canister from space crashed through Florida home last month. Here's what was inside. The post What Was the NASA Space Trash That Plunked Through a Florida Home Made Of? appeared first on ...

- Rare WW2 Photo Reconnaissance Spitfire Was Just Rebuilt After 76 Years

A rare World War II Photo Reconnaissance Spitfire, which had been shot down by German forces in 1942 and remained lost until its recovery from a Norwegian peat bog 76 years later, is undergoing ...

- Eagle Farm preview and tips: $6 best bet [Saturday, April 27]

Queensland form man Graeme Carey have provided his race-by-race form analysis and tips for Saturday's Eagle Farm meeting.

- Team helps rebuild WW2 Spitfire lost for 76 years in Norwegian wilderness

Engine parts from a rare Second World War Photo Reconnaissance Spitfire that was shot down by German armed forces in 1942 and lost until being recovered from a Norwegian peat bog 76 years later are ...