Imagine being able to test your food in your very own kitchen to quickly determine if it carried any deadly microbes.

Research conducted at Lawrence Berkeley National Laboratory (Berkeley Lab) and now being commercialized by Optokey may make that possible.

Optokey, a startup based in Hayward, California, has developed a miniaturized sensor based on Raman spectroscopy that can quickly and accurately detect or diagnose substances at a molecular level. “Our system can do chemistry, biology, biochemistry, molecular biology, clinical diagnosis, and chemical analysis,” said company president and co-founder Fanqing Frank Chen. “And our system can be implemented very cheaply, without much human intervention.”

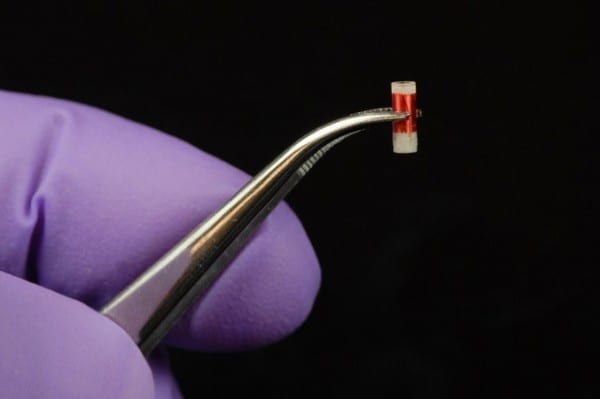

The technology is based on surface-enhanced Raman spectroscopy, a technique for molecular fingerprinting. While SERS is a highly sensitive analytical tool, the results are not easily reproducible. As a scientist at Berkeley Lab, Chen and colleagues developed a solution to this problem using what they called “nanoplasmonic resonators,” which measures the interaction of photons with an activated surface using nanostructures in order to do chemical and biological sensing. The method produces measurements much more reliably.

“At Optokey we’re able to mass produce this nanoplasmonic resonator on a wafer scale,” Chen said. “We took something from the R&D realm and turned it into something industrial-strength.”

The miniaturized sensors use a microfluidic control system for “lab on a chip” automated liquid sampling. The company is taking a page from the semiconductor industry in making its chip. “We’re leveraging knowledge acquired from high-tech semiconductor manufacturing methods to get the cost, the volume, and the accuracy in the chip,” said VP of Manufacturing Robert Chebi, a veteran of the microelectronic industry who previously worked at Lam Research and Applied Materials. “We’re also leveraging all the knowledge in lasers and optics for this specific Raman-based method.”

Chebi calls Optokey’s product a “biochemical nose,” or an advanced nanophotonic automated system, with sensitivity to the level of a single molecule, far superior to sensors on the market today. “Today’s detection and diagnosis methods are far from perfect—detection limits are in PPM (parts per million) and PPB (parts per billion),” he said. “Also, our system can provide information in minutes, or even on a continuous basis, versus other methods where it could take hours or even days, if samples have to be sent to another lab.”

The potential applications, he says, are vast, including food safety, environmental monitoring (of both liquids and gases), medical diagnosis, and chemical analysis. Optokey’s customers include a major European company interested in food safety, a Chinese petrochemical company interested in detecting impurities in its products, and a German company interested in point-of-care diagnosis.

Read more: Berkeley Lab Spinoff Company Makes Fast, Accurate Nanoscale Sensor

The Latest on: Nanoscale Sensor

[google_news title=”” keyword=”Nanoscale Sensor” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Nanoscale Sensor

- Research Roundup: Sunscreen shields from sun and unsustainabilityon May 2, 2024 at 10:20 pm

Stanford researchers challenged the boundaries of sustainability, by protecting coral reefs and designing a sunscreen better for the skin and the planet.

- Mitsubishi, Denka Collaborate for Fullerene Businesson May 2, 2024 at 12:24 am

Under a joint venture agreement between Denka and Mitsubishi Corporation, Denka will acquire from Mitsubishi a 50 % stake in Frontier Carbon Corporation, a company dedicated to the manufacturing and ...

- Revolutionizing Technology: Spintronics Market Surges, Expected to Reach US$ 1.4 Billion by 2033on April 29, 2024 at 5:18 am

Spintronics Market is set to cross worth of US$ 1,394.2 Million at 7.3% CAGR during forecast period 2023 to 2033 | Data analysis by Future Market Insights, Inc.

- Imaging Technique Shows New Details of Alzheimer’s Peptide Structureson April 29, 2024 at 1:38 am

A new imaging technique developed by engineers at Washington University in St. Louis can give scientists a much closer look at fibril assemblies — stacks of peptides that include amyloid beta, most ...

- Unlocking New Potentials: Halting Light in Photonic Crystals Offers Photonic Device Innovationon April 29, 2024 at 12:03 am

Advanced technologies in photonic devices such as LED displays, fiber-optics, sensors, and lasers could see a significant leap forward thanks to innovative ways of manipulating light, including ...

- Light Waves Brought to a Stop in a Crystal Promises New Ways to Control Photonson April 28, 2024 at 11:53 pm

Finding new ways to slow fleeting waves of light or even stop them in their tracks could lead to more advanced photonic devices, such as lasers, LED displays, fiber-optics, and sensors.

- New imaging technique provides a much closer look at fibril assemblieson April 26, 2024 at 10:47 pm

A new imaging technique developed by engineers at Washington University in St. Louis can give scientists a much closer look at fibril assemblies, stacks of peptides like amyloid beta, most notably ...

- Failure Analysis Equipment Market To Reach USD 8.7 Billion By 2032 | DataHorizzon Researchon April 26, 2024 at 1:30 am

The failure analysis equipment market size was valued at USD 4.5 Billion in 2022 and is expected to be valued at USD 8.7 Billion by 2032 at a CAGR of 6.8%.

- Imaging technique shows new details of peptide structureson April 24, 2024 at 11:19 am

A new imaging technique developed by engineers at Washington University in St. Louis can give scientists a much closer look at fibril assemblies—stacks of peptides that include amyloid beta, most ...

- Sound and vision: synchrotron insights illuminate crystal nucleation and growthon April 24, 2024 at 7:44 am

Curiosity-driven research using low-power ultrasound fields to investigate the fundamental physics of crystal nucleation – the formation of crystal nuclei and “embryos” in the liquid or solution phase ...

via Bing News