When petroleum companies abandon an oil well, more than half the reservoir’s oil is usually left behind as too difficult to recover.

Now, however, much of the residual oil can be recovered with the help of nanoparticles and a simple law of physics.

Oil to be recovered is confined in tiny pores within rock, often sandstone. Often the natural pressure in a reservoir is so high that the oil flows upwards when drilling reaches the rocks containing the oil.

Less oil without water

In order to maintain the pressure within a reservoir, oil companies have learned to displace the produced oil by injecting water. This water forces out the oil located in areas near the injection point. The actual injection point may be hundreds or even thousands of metres away from the production well.

Eventually, however, water injection loses its effect. Once the oil from all the easily reached pores has been recovered, water begins emerging from the production well instead of oil, at which point the petroleum engineers have had little choice but to shut down the well.

The petroleum industry and research community have been working for decades on various solutions to increase recovery rates. One group of researchers at the Centre for Integrated Petroleum Research (CIPR) in Bergen, collaborating with researchers in China, has developed a new method for recovering more oil from wells – and not just more, far more.

The Chinese scientists had already succeeded in recovering a sensational 15 per cent of the residual oil in their test reservoir when they formed a collaboration with the CIPR researchers to find out what had actually taken place down in the reservoir. Now the Norwegian partner in the collaboration has succeeded in recovering up to 50 per cent of the oil remaining in North Sea rock samples.

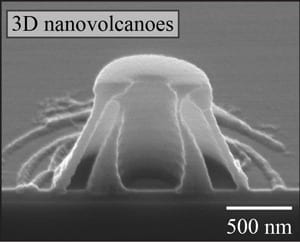

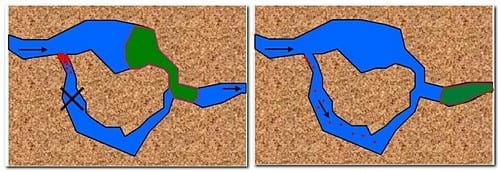

To achieve these high recovery rates, the researchers make use of a simple physical phenomenon depicted in the figure below

Nano-scale traffic jams

Water in an oil reservoir flows much like the water in a river, accelerating in narrow stretches and slowing where the path widens.

When water is pumped into a reservoir, the pressure difference forces the water away from the injection well and towards the production well through the tiny rock pores. These pores are all interconnected by very narrow tunnel-like passages, and the water accelerates as it squeezes its way through these.

The new method is based on infusing the injection water with particles that are considerably smaller than the tunnel diameters. When the particle-enhanced water reaches a tunnel opening, it will accelerate faster than the particles, leaving the particles behind to accumulate and plug the tunnel entrance, ultimately sealing the tunnel.

This forces the following water to take other paths through the rock’s pores and passages – and in some of these there is oil, which is forced out with the water flow. The result is more oil extracted from the production well and higher profits for the petroleum companies.

The Latest Bing News on:

Oil recovery

- CAG: OIL suffers multi-crore losses due to delayed projectson May 7, 2024 at 4:13 pm

Oil India Limited (OIL) faces significant financial losses due to delays and anomalies in its projects, as highlighted in a recent audit report by the comptroller and auditor General (CAG). The report ...

- Clean energy ETFs start to outperform key oil & gas ETFon May 7, 2024 at 8:49 am

After a rough couple of years, exchange-traded funds (ETFs) tied to clean energy generation and distribution are starting to outperform investor vehicles centred on oil and gas exploration and ...

- Oil, gas investment remains quickest economic recovery for Nigeria — Ministeron May 7, 2024 at 2:31 am

Mr Heineken Lokpobiri, Minister of State for Petroleum Resources (Oil), says the quickest way toward economic recovery for Nigeria is through oil and gas investment.Lokpobiri disclosed this in an ...

- Market expects oil price recovery; buy the dip within $76-82 rangeon May 6, 2024 at 6:25 pm

Gasoline stocks jumped by 300,000 barrels in the week to 227.1 million barrels, compared with forecasts for a 1.1-million-barrel draw ...

- XTO Energy to start enhanced oil recovery project in Dunn Countyon May 6, 2024 at 11:25 am

The North Dakota Industrial Commission approved a pilot project from XTO Energy to start enhanced oil recovery (EOR).The application lists four wells in Dunn County south of Johnson’s Corner.XTO said ...

- Big Oil finds more to love in deepwater exploration fieldson May 5, 2024 at 7:05 am

As Big Oil returns this week to the industry's annual showcase for offshore energy projects and equipment in Houston, deepwater discoveries off Guyana, Namibia and the U.S. Gulf Coast will take the ...

- His Texas ranch is littered with a century of oil and gas waste. He’s fighting backon May 3, 2024 at 1:00 am

For one West Texas rancher, the rampant orphaned wells have become both a mission and an existential threat. Dressed in a dark plaid button down and jeans with a rodeo belt buckle, Schuyler Wight ...

- Enhanced oil recovery project OKd for Bakken-Three Forks wells in Dunn Countyon May 1, 2024 at 7:28 am

North Dakota's Industrial Commission has given the okay for an enhanced oil recovery pilot project in Dunn County. It’s proposed by XTO Energy, a subsidiary of Exxon-Mobil. And it would involve Bakken ...

- Top 5 Oil and Gas Stocks on the TSX and TSXV in 2024on April 30, 2024 at 1:45 pm

The first quarter of 2024 saw increasing trends in Brent Crude and West Texas Intermediate prices, attributed to ongoing tensions from the Russia-Ukraine conflict and global economic conditions. OPEC ...

- PetroChina Profit Rises as Economic Recovery Remains Unevenon April 29, 2024 at 1:48 am

PetroChina Co. recorded its highest first-quarter profit amid steady global oil prices and even as China’s economic rebound struggles to gain traction.

The Latest Google Headlines on:

Oil recovery

[google_news title=”” keyword=”oil recovery” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Oil recovery rate

- Market expects oil price recovery; buy the dip within $76-82 rangeon May 6, 2024 at 6:25 pm

Gasoline stocks jumped by 300,000 barrels in the week to 227.1 million barrels, compared with forecasts for a 1.1-million-barrel draw ...

- Survey says: Economic recovery holds sway in oil price ups and downson April 30, 2024 at 9:08 pm

Oil & Gas Middle East poll reveals economic recovery patterns as primary driver of oil price fluctuations. Survey says: Economic recovery holds sway in oil price ups and downs. ANALYSIS, Exploration & ...

- Indian Rupee Shows Marginal Recovery Against US Dollaron April 30, 2024 at 8:44 am

The Indian rupee strengthened by 2 paise against the US dollar, reaching 83.43, due to foreign capital inflows. Despite initial resistance from a strong dollar and rising oil prices, the rupee ...

- Crude Oil News Today: Will Rising Inflation Dampen Demand Recovery?on April 27, 2024 at 3:01 am

Furthermore, high inflation rates quashed hopes that the Federal ... Assuming no major negative developments, the oil market might lean towards a bullish trend, supported by signs of economic recovery ...

- Crude Oil News Today: Will Rising Inflation Dampen Demand Recovery?on April 26, 2024 at 11:04 pm

Furthermore, high inflation rates quashed hopes ... negative developments, the oil market might lean towards a bullish trend, supported by signs of economic recovery and tight supply conditions ...

- Oil Stabilizes as Fears of Wider Middle East War Fadeon April 23, 2024 at 1:59 am

0752 GMT – Oil prices are broadly stable on Tuesday after ... PCE data this week for more cues on the timeline of interest-rate cuts. ([email protected]) ...

- Oil, gold and the dollar are surging. Here’s why that could derail the Fed’s rate-cut outlook.on April 3, 2024 at 8:38 pm

A global economic recovery is fueling a blistering commodities ... and potentially clouding its path to cutting interest rates by mid-year, according to market strategists. From oil and gasoline ...

- Probing oil fieldson October 24, 2023 at 11:27 pm

Such sensors are being used to map reservoirs, understand how they develop and to monitor the processes used to separate oil, gas and water. The recovery rate from oil reservoirs at present is of ...

- How Does Gas Injection Work?on August 26, 2022 at 9:24 pm

A type of Enhanced Oil Recovery (EOR), secondary production includes ... thus increasing the production rate of the well. Furthermore, a type of EOR employed on a well in the tertiary production ...

The Latest Google Headlines on:

Oil recovery rate

[google_news title=”” keyword=”oil recovery rate” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]