Graphene is gaining heated attention, dubbed a “wonder material” with great conductivity, flexibility and durability.

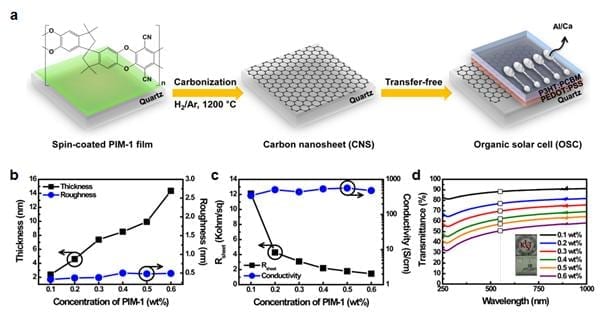

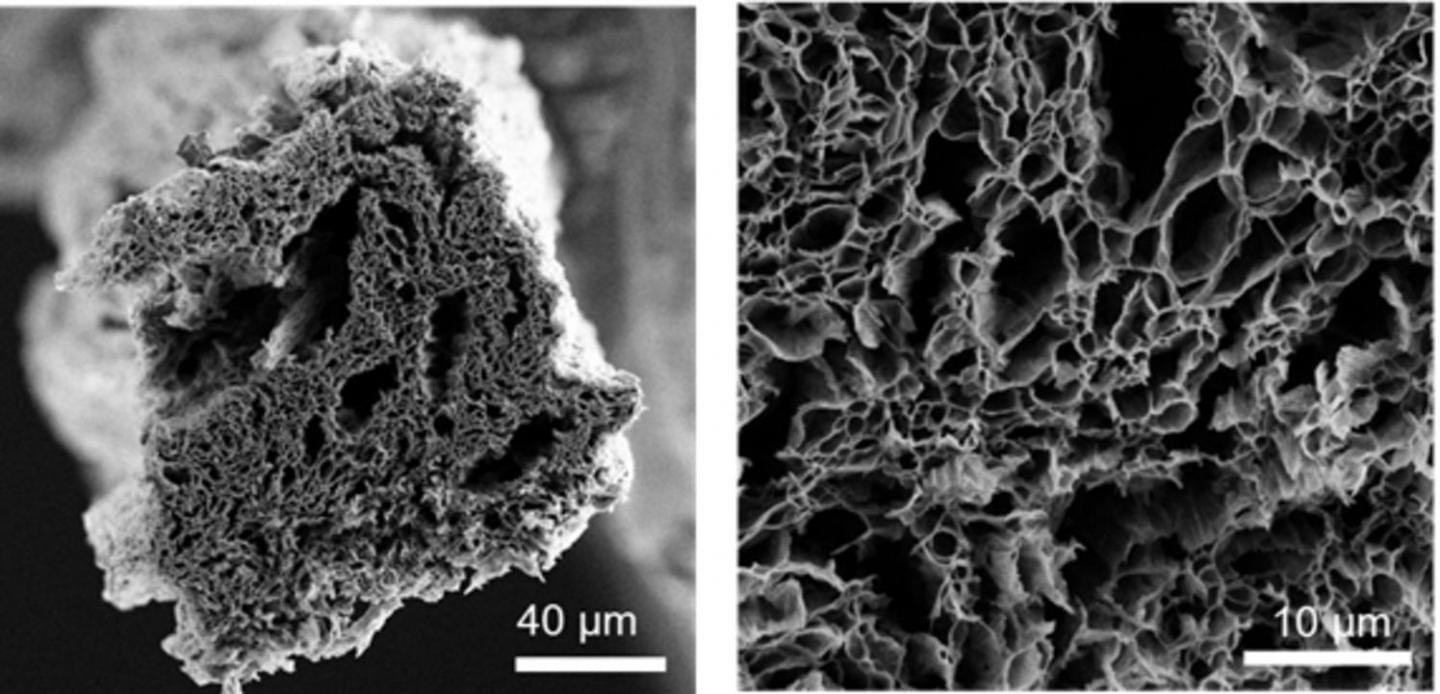

However, graphene is hard to come by due to the fact that its manufacturing process is complicated and mass production not possible. Recently, a domestic research team developed a carbon material without artificial defects commonly found during the production process of graphene while maintaining its original characteristics. The newly developed material can be used as a substitute for graphene in solar cells and semiconductor chips. Further, the developed process is based on the continuous and mass-produced process of carbon fiber, making it much easier for full-scale commercialization. In recognition of the innovative approach, the research was introduced on the cover of Nanoscale, a high impacting peer-reviewed journal in the field of nano science.

The carbon nanosheet can be mass-produced in a simpler process while having high quality since the new process bypasses the steps that are prone to formation of defects such as elimination of the metal substrate or transfer of graphene to another board. The final product is as effective as graphene.

Read more . . .

The Latest on: Carbon nanosheet

[google_news title=”” keyword=”Carbon nanosheet” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Carbon nanosheet

- Carbon Marketson May 8, 2024 at 2:52 am

Reuters, the news and media division of Thomson Reuters, is the world’s largest multimedia news provider, reaching billions of people worldwide every day. Reuters provides business, financial ...

- Expert-Defying Anomaly – Scientists Discover 2D Nanomaterial With Counter-Intuitive Expanding Propertieson April 25, 2024 at 5:25 am

It is a common hack to stretch a balloon out to make it easier to inflate. When the balloon stretches, the width crosswise shrinks to the size of a string. Noah Stocek, a PhD student collaborating ...

- Rolls-Royce Spectre Gets Carbon-Fiber Makeover By Mansoryon April 24, 2024 at 5:00 pm

Mansory's extreme Spectre conversion includes visible carbon accents, massive vents, and 23-24 inch polished wheels. The interior of the Spectre is transformed with leather and carbon fiber ...

- Carbon offsets too often don’t deliver. Inside the race to fix them.on April 18, 2024 at 1:14 pm

in 2021. (Charlie Riedel/AP) They are marketed as a solution for companies and consumers looking to erase their carbon footprint, with promises that money spent on “offsets” will go to ...

- Breakthrough CO2-fueled generator turns greenhouse gas into electricityon April 18, 2024 at 11:38 am

Strategies for carbon capture, utilization ... The group devised a solution: a nanosheet-agarose hydrogel (NaH) composite-based generator that can produce power directly from CO2 adsorption ...

- Carbon price fall deprives Europe's green funds of billionson April 17, 2024 at 5:00 pm

FLORENCE/BERLIN, April 18 (Reuters) - A drop in the European Union's carbon price this year could mean that a fund intended to be among the world's biggest schemes for new green technologies will ...

- Two-dimensional nanomaterial sets expansion recordon April 17, 2024 at 2:08 pm

The Western-engineered tungsten semi-carbide nanosheet can expand to 40%, a new world record. "We were specifically looking to create a two-dimensional nanomaterial from tungsten semi-carbide ...

- Two-dimensional nanomaterial sets expansion recordon April 16, 2024 at 5:01 pm

The trick is that the structure of the nanosheet itself isn't flat. The atoms in the sheet are made of repeating units consisting of two tungsten atoms for every carbon atom, which are arranged ...

- Two-dimensional nanomaterial sets record for expert-defying, counter-intuitive expansionon April 16, 2024 at 5:01 pm

The trick is that the structure of the nanosheet itself isn't flat. The atoms in the sheet are made of repeating units consisting of two tungsten atoms to every carbon atom, which are arranged ...

- Our plans to tackle climate change with carbon storage don't add upon April 15, 2024 at 5:00 pm

Plans to tackle climate change by sucking carbon dioxide from the air and storing it underground are wildly unrealistic, according to a new analysis, calling into question our ability to meet ...

via Bing News