via Swanson School of Engineering

For years, scientists speculated that the heart’s helical arrangements and complex musculature pumps blood more efficiently throughout the body. Though thanks to the difficulty in reproducing such complex and intricate details in artificial hearts, researching this phenomenon proved difficult.

However, in a new study published in Science, a team of researchers from multiple institutions have come together to utilize a new, more advanced method to fabricate artificial tissues and organs. This team included Qihan Liu, an assistant professor in the University of Pittsburgh Swanson School of Engineering.

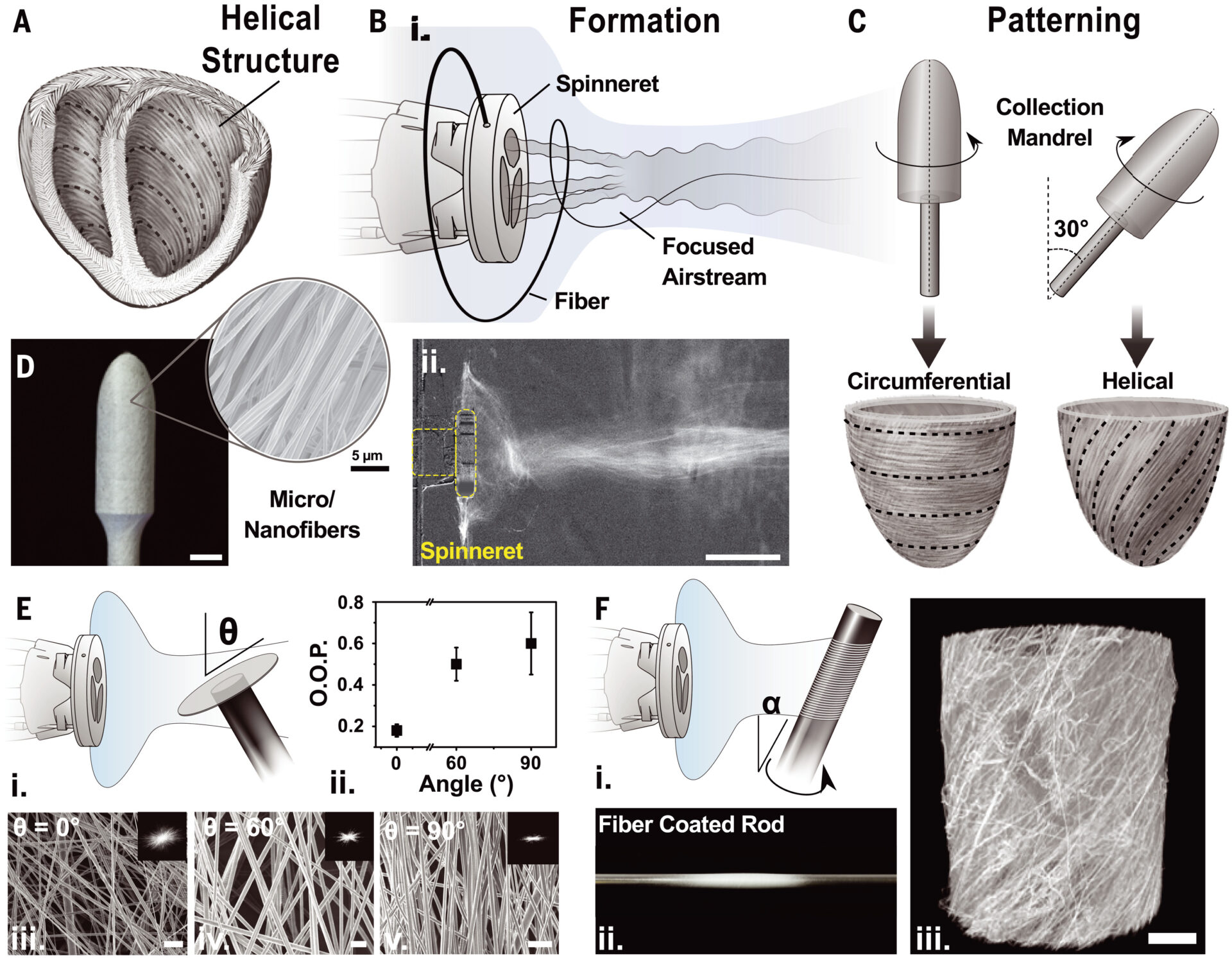

“It is a huge manufacturing challenge to make material that mimics biological tissue,” Liu said. “Biological tissues consist of various micro/nanofibers of complex spatially varying alignment. The arrangement of these fibers is how nature program the rich mechanical behavior of biological tissue. However, currently there is no manufacturing tool that can capture this complex arrangement. While common 3D printing methods can easily realize complex fiber arrangements, 3D printing cannot print nanofibers at a throughput relevant to tissue engineering. While established nanofiber spinning techniques such as electrospinning can produce nanofibers at mass-production-level high throughput, complex fiber arrangement has yet to be realized.”

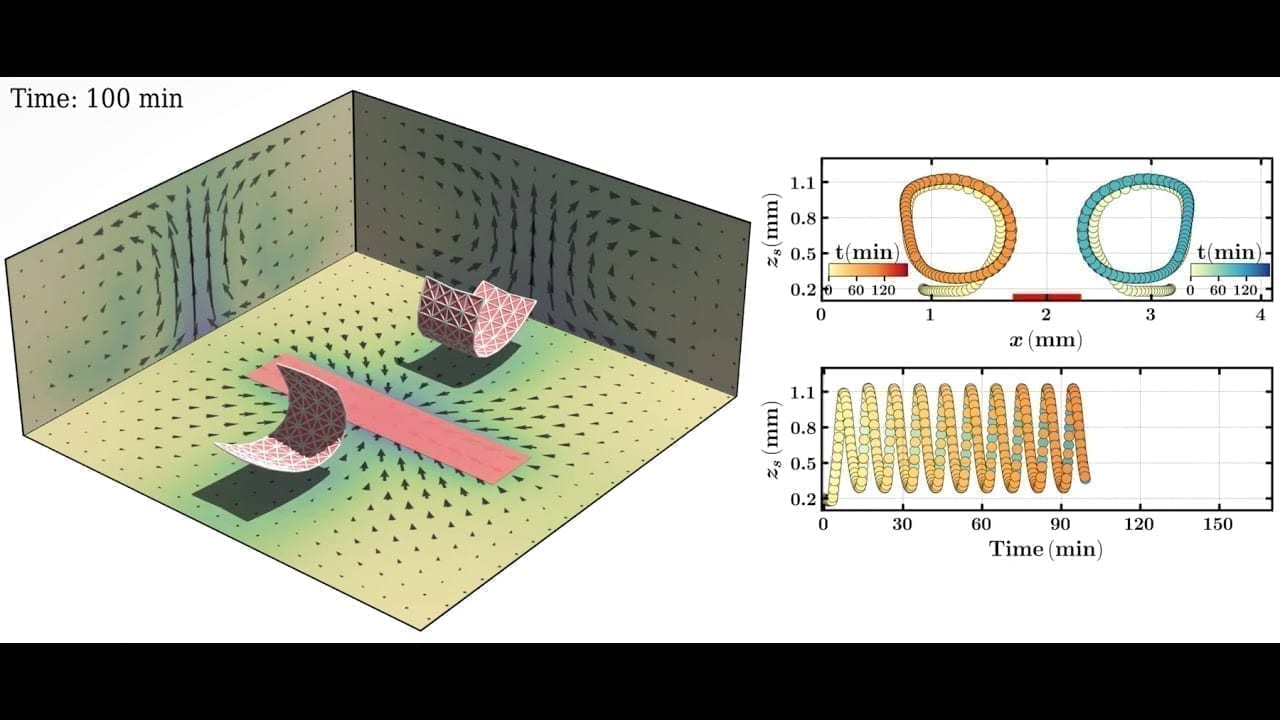

The researchers thus proposed the process of focused rotary jet spinning. FRJS is an additive manufacturing method which uses centrifugal spinning to rapidly form fibers. The fibers are subsequently focused, aligned, and deposited onto targeted locations with a controlled airstream. By using airflow, this method allows thousands of micro/nanofibers to be simultaneously manipulated, which ensures high throughput. With the specially designed airflow, FRJS can manufacture 3D fiber constructs that are much more complex than current methods can create.

The researchers compare their methods to two other ways of producing artificial organs and tissue: 3D printing and fiber spinning. Although 3D printing continues to contribute major advancements to the development of artificial organs and tissue, the researchers counter that 3D printing takes too long to achieve the detail and complexity FRJS can offer.

Another currently used method is fiber spinning, which allows for a faster production but not as much detail or complexity as FRJS. Thus, the researchers present FRJS as a method to make more complex creations in a timelier manner.

To display the possibilities of FRJS in this context, the researchers used the process to create samples, including a full-scale fiber human heart model to show the capability of manufacture complex 3D structure, a three layer dual-chamber ventricle model to show the capability to capture complex fiber alignment in biological tissues and single-layer ventricles with the size of a rat, cat, human and the 12,000-pound minke whale to show the scalability of the manufacturing process. The researchers also demonstrate how models like these created by FRJS can be used to understand the function of the helical cell arrangements within the heart.

These samples, however, are just one display of what can be done with FRJS.

“This paper is just one demonstration of what can be done with this method, really,” Liu said. “The sky is the limit.”

In the future, Liu said, FRJS could be used to recreate blood vessels, cartilage and other fiber-reinforced tissues. That would offer countless possibilities in mimicking biological tissues in robotics, engineering and more. Fiber-reinforced composite made with FRJS could even be utilized to build cars and airplanes with lighter fiber-reinforced materials that use optimized fiber arrangements to better handle the load.

Original Article: Study: Making an artificial heart fit for a human — with focused rotary jet spinning, not 3D

More from: Swanson School of Engineering

The Latest Updates from Bing News & Google News

Go deeper with Bing News on:

Focused rotary jet spinning

- Gaming News

In which we obsess over switch types, mounting styles, keycap profiles, stabs and rotary knobs. Here's everything you need to know before buying a mechanical keyboard, plus the best mechanical ...

- Ranked: the highest-revving car engines ever made

At the heart of this track-focused model is the same 5.2-liter V10 ... Top speed is 93mph, so you can revel in its quick spinning nature with a clear conscience. Honda’s experience with ...

- The Russian Air Force’s Old Su-27 Fighters Had A Lucky War. Until This Week.

A video that circulated on social media depicts the jet spinning toward the ground, on fire. Reportedly, the pilot ejected and survived. Still, the Ukrainian defense ministry “should start ...

- How to easily beat Custom Valkyrie in Final Fantasy 7 Rebirth

Custom Valkyrie is one of the Final Fantasy 7 Rebirth bosses, and this encounter takes place on the way to the Corel Reactor. This boss might look familiar, from both Final Fantasy 7 Remake, and ...

- ALFVF Alfa Laval Corporate AB

It also provides sensing and control, cleaning validation, condition monitoring, agitators, tank, powder mixers, fittings, and tubes, as well as wall mounted cleaning nozzles, rotary jet and heads ...

Go deeper with Google Headlines on:

Focused rotary jet spinning

[google_news title=”” keyword=”focused rotary jet spinning” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]

Go deeper with Bing News on:

Fabricating artificial tissues and organs

- Nearly 1,300 in Denver metro area in need of life-saving organ and tissue transplants

Donors are being honored during the month of April along with their families who agree to donate an organ, eye, and tissue.

- Henry Ford Health surgeon emphasizes importance of organ transplants in minority communities

DETROIT – April is Donate Life Month, an opportunity to educate everyone about the importance of the gift of life.

- UNC researchers create artificial cells that act like living cells

The scientific breakthrough could impact regenerative medicine, drug delivery systems and diagnostic tools one day.

- Scientists create artificial cells with capabilities for biomedical advancements

Researchers at the University of North Carolina , have successfully created artificial cells capable of mimicking natural cellular behaviour ...

- Microplastics Are Invading Our Brains and Organs, UNM Study Sounds Alarm

Researchers at the University of New Mexico have recently published another paper pointing to microplastics’ impact on our digestive systems and their ability to travel to several of our ...

Go deeper with Google Headlines on:

Fabricating artificial tissues and organs

[google_news title=”” keyword=”fabricating artificial tissues and organs” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]