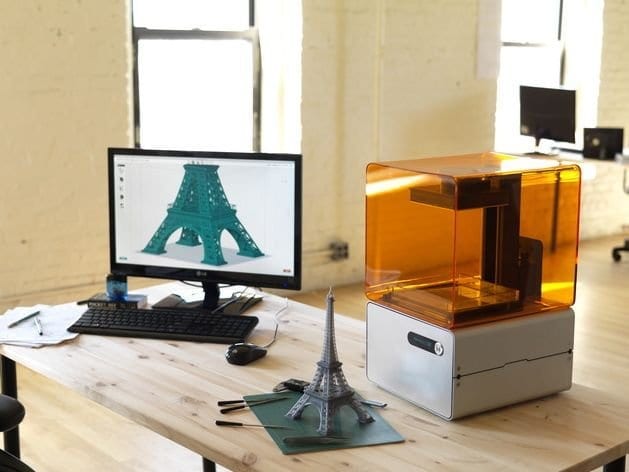

FABRICATED: The New World of 3D Printing is a text that works to illuminate 3D printing’s role in undermining the rigidity of manufacturing.

This is accomplished by providing an on-demand production tool that product designers, students, doctors, and others can benefit from. Authors Hod Lipson and Melba Kurman convey a level-headedness and cautious enthusiasm that is refreshing. Instead of pushing the idea that every home will have a 3D printer in the future, they spend considerable time envisioning alternative scenarios by analyzing different types of enthusiast communities, how and why they’re gaining market traction. In their book you will find coverage of various science experiments, educational initiatives, the creative thinking of large companies like 3D Systems, and more consumer-facing platforms like Makerbot and Shapeways.

The secret to 3D printing could be summed up as follows: 3D printers are more accurate and versatile than any other mode of production — be it a human or machine — at fabricating complex design into a physical object, combining raw materials in ways that were once impossible.

The book explains the world of 3D printing in all its technologies, design tools, and downstream implications, covering corporate R&D labs to the DIY initiatives we see in the DIY and Maker communities. FABRICATED does a great job in explaining how the technology has gained traction in industries including electronics, automotive, aerospace and the medical community. It also dedicates a good portion of the book to explaining more conceptual areas such as 3D printed food. Below is a summary of the key takeaways from the book.

A Historical Overview of 3D Printing

As new as it seems, 3D printing has been around since the late 80’s. For decades, a niche community of enthusiasts have been exploring the possibilities of this technology. Initially, it was referred to as ‘additive manufacturing’ and the text develops the idea that the word “print” is ultimately more approachable than ‘manufacture’ or ‘fabricate’.

The authors see 3D printing as a way of gaining control over composition. This means the birth of “programmable matter” or “intelligent materials”. They see an eventual convergence of virtual and physical worlds, “first we will gain control over the shape of physical things. Then we will gain new levels of control over the composition, the materials they’re made of. Finally, we will gain control over the behavior of physical things.” The biggest future-forward implication of this is doctors gaining the ability to ‘print’ organic material like body parts and food. The book dedicates the entirety of its seventh chapter to discussing bioprinting, which may include the development of artificial limbs to the engineering of tissue, stem cells using bio-ink and bio-paper. And this is followed by a chapter on the realities of printing food.

The book actually leaps into these future implications early on in chapter 1, which presents is an imaginative take on how life may be in a future where everything from functional food to a toothbrush can be printed. This is quickly followed by a more historicized understanding that articulates the 10 Principles of 3D Printing (e.g. makers don’t need to pay extra for complex designs, 3D printed objects don’t require assembly, that digital precision will enable to replicate physical objects).

The Question of Scale and Impact on Businesses

As mentioned, the authors believe that 3D printing is slated to merge digital and physical creativity. Based on this, it will also bring together the benefits of craftsmanship and mass production together by enabling smaller players to compete more directly with larger players. In their third chapter, they dedicate time to looking at how 3D printing is “somewhere between mass production and the local farmer’s market.” They elaborate to say that while 3D printing as a process is not very scaleable for a company selling large volumes of a product with thin margins, “small companies have access to powerful tools that were once available only to global corporations. Resourceful businesses, armed with a 3D printer and design software, can provide skilled services of a caliber that were once the exclusive domain of corporate in-house design and engineering departments.” This is, in a nutshell, how it will impact the design business environment.

The Latest Bing News on:

3D Printing

- ‘Faster, better, cheaper’ homes: Venture seeks to bring 3D printing construction to Guamon April 26, 2024 at 2:53 pm

An affordable concrete home, with walls, plumbing and electrical fixtures built and installed in one day’s time?

- World's biggest 3D printer whirs into actionon April 26, 2024 at 7:09 am

A giant 3D printer, which is big enough to make a house, has been unveiled at the University of Maine. The university says it has beaten its own record for the world's largest polymer 3D printer - with the new printer four times bigger than the previous machine.

- World's biggest 3D printer unveiled in Maine may one day create entire neighborhoodson April 24, 2024 at 9:14 am

ORONO, Maine - The world's largest 3D printer has created a house that can cut construction time and labor. An even larger printer unveiled on Tuesday may one day create entire neighborhoods. The machine revealed Tuesday at the University of Maine is four ...

- Could Your Next Chair Be 3D Printed? Exploring the Viability of 3D Printing in Furniture Productionon April 24, 2024 at 8:55 am

Desktop 3D printers have undergone a revolution in the past year with the introduction of very high speed devices, in some cases able to print at speeds up to 10X of the earlier devices. This same speed-up tech can now be ported to larger format FFF 3D printers, and that should dramatically cut down on the cost to produce parts.

The Latest Google Headlines on:

3D Printing

[google_news title=”” keyword=”3D Printing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Additive manufacturing

- Fonon Highlights Its Zero Width Laser Cutting Solution for Flat Panel Display Manufacturingon April 26, 2024 at 12:02 pm

Fonon Corporation, a multi-market holding company, R&D center, equipment designer and manufacturer of advanced laser material processing systems for subtractive and additive manufacturing, highlights ...

- GE Additive rebrands as Colibrium Additive, retires Concept Laser and Arcam brandingon April 26, 2024 at 3:45 am

GE Additive has relaunched as Colibrium Additive. It was also announced that Concept Laser and Arcam EBM legacy brands will be retired.

- INDO-MIM taps 3D printing in precision manufacturingon April 25, 2024 at 6:27 pm

The precision metal parts manufacturer is using HP’s Metal Jet S100 printers to produce components using metal powder for the automotive, healthcare and other industries ...

- UltiMaker Targets Experienced Additive Manufacturers with New Factor 4on April 25, 2024 at 8:43 am

Industrial-grade 3D printer focuses on reliability, with automatic material handling and in-process monitoring.

- GE Additive rebrands as Colibrium Additive; Concept Laser & Arcam brands to be retiredon April 25, 2024 at 8:29 am

GE Additive has rebranded as Colibrium Additive, after GE split into three public companies earlier this month. Colibrium Additive will operate under the GE Aerospace umbrella.

- AMGTA releases preliminary research on sustainability of powder and wire additive feedstockon April 25, 2024 at 5:23 am

AMGTA has announced the preliminary results of a research project titled ‘Specific Energy of Metal AM Feedstock: A Comparison.’ ...

- AMGTA research explores sustainability of metal additive manufacturing feedstockon April 25, 2024 at 3:11 am

The study was conducted with Syntec Associates and Divergent Technologies to determine specific energy requirements for producing metal 3D printing materials via three key processes.

- Martinrea International Inc. Announces Investment in Equispheres Inc., a Supplier of High-Performance Powders for Additive Manufacturingon April 23, 2024 at 2:00 pm

TORONTO, April 23, 2024 (GLOBE NEWSWIRE) -- (TSX:MRE) a diversified and global automotive supplier engaged in the design, development and manufacturing of highly engineered, value-added Lightweight ...

- AFRL Uses Additive Manufacturing to Make Single-Block Rocket-Engine Thrust Chamberon April 22, 2024 at 7:00 am

The AFRL has announced that it has turned to laser powder DED additive manufacturing to create a rocket-engine thrust chamber.

- Vietnam Hybrid Additive Manufacturing Machine Market Key Segments, Share, Size, Trends, Growth, and Forecast 2024 to 2032on April 17, 2024 at 1:55 pm

The recent analysis by Report Ocean on the “Vietnam Hybrid Additive Manufacturing Machine Market” Report 2024 to 2032 revolves around various aspects of the market, including characteristics, size and ...

The Latest Google Headlines on:

Additive manufacturing

[google_news title=”” keyword=”additive manufacturing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]