CREDIT

Aldo Lobos

Although rechargeable batteries in smartphones, cars and tablets can be charged again and again, they don’t last forever. Old batteries often wind up in landfills or incinerators, potentially harming the environment. And valuable materials remain locked inside. Now, a team of researchers is turning to naturally occurring fungi to drive an environmentally friendly recycling process to extract cobalt and lithium from tons of waste batteries.

The researchers will present their work today at the 252nd National Meeting & Exposition of the American Chemical Society (ACS). ACS, the world’s largest scientific society, is holding the meeting here through Thursday. It features more than 9,000 presentations on a wide range of science topics.

“The idea first came from a student who had experience extracting some metals from waste slag left over from smelting operations,” says Jeffrey A. Cunningham, Ph.D., the project’s team leader. “We were watching the huge growth in smartphones and all the other products with rechargeable batteries, so we shifted our focus. The demand for lithium is rising rapidly, and it is not sustainable to keep mining new lithium resources,” he adds.

Although a global problem, the U.S. leads the way as the largest generator of electronic waste. It is unclear how many electronic products are recycled. Most likely, many head to a landfill to slowly break down in the environment or go to an incinerator to be burned, generating potentially toxic air emissions.

While other methods exist to separate lithium, cobalt and other metals, they require high temperatures and harsh chemicals. Cunningham’s team is developing an environmentally safe way to do this with organisms found in nature — fungi in this case — and putting them in an environment where they can do their work. “Fungi are a very cheap source of labor,” he points out.

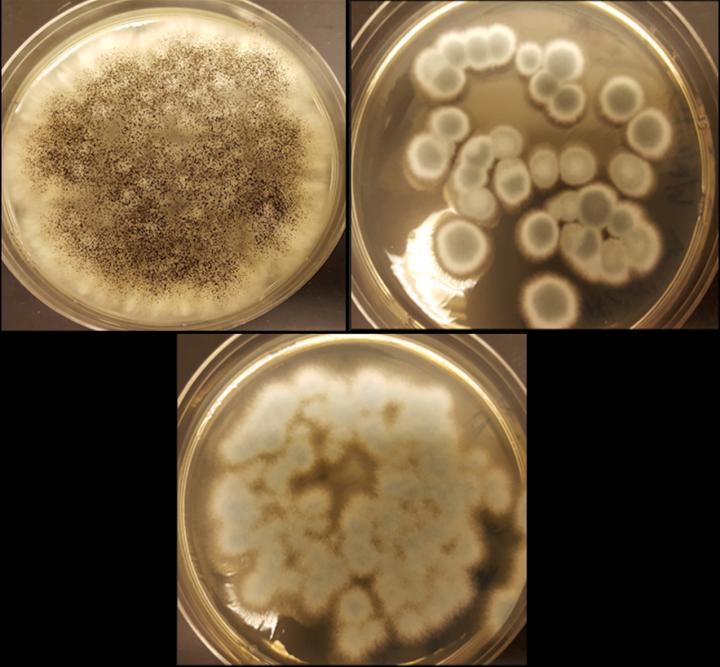

To drive the process, Cunningham and Valerie Harwood, Ph.D., both at the University of South Florida, are using three strains of fungi — Aspergillus niger, Penicillium simplicissimum andPenicillium chrysogenum. “We selected these strains of fungi because they have been observed to be effective at extracting metals from other types of waste products,” Cunningham says. “We reasoned that the extraction mechanisms should be similar, and, if they are, these fungi could probably work to extract lithium and cobalt from spent batteries.”

The team first dismantles the batteries and pulverizes the cathodes. Then, they expose the remaining pulp to the fungus. “Fungi naturally generate organic acids, and the acids work to leach out the metals,” Cunningham explains. “Through the interaction of the fungus, acid and pulverized cathode, we can extract the valuable cobalt and lithium. We are aiming to recover nearly all of the original material.”

Results so far show that using oxalic acid and citric acid, two of the organic acids generated by the fungi, up to 85 percent of the lithium and up to 48 percent of the cobalt from the cathodes of spent batteries were extracted. Gluconic acid, however, was not effective for extracting either metal.

The cobalt and lithium remain in a liquid acidic medium after fungal exposure, Cunningham notes. Now his focus is on how to get the two elements out of that liquid.

“We have ideas about how to remove cobalt and lithium from the acid, but at this point, they remain ideas,” he says. “However, figuring out the initial extraction with fungi was a big step forward.”

Other researchers are also using fungi to extract metals from electronic scrap, but Cunningham believes his team is the only one studying fungal bioleaching for spent rechargeable batteries.

Cunningham, Harwood and graduate student Aldo Lobos are now exploring different fungal strains, the acids they produce and the acids’ efficiencies at extracting metals in different environments.

Learn more: Fungi recycle rechargeable lithium-ion batteries

The Latest on: Fungi extracting metals from scrap

[google_news title=”” keyword=”Fungi extracting metals from scrap” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Fungi extracting metals from scrap

- Obtaining and using metals - EdexcelBiological methods of metal extraction - Higheron April 24, 2024 at 10:55 am

Since iron is cheaper than copper, the use of scrap iron is a cost-effective way to produce copper from the leachate.

- Extracting Pure Gold From Electrical Trash Just Got Easieron April 23, 2024 at 7:18 am

Using fibers, researchers can extract nearly 100 percent of gold from electronic waste, much more than previous methods.

- Sustainable Solutions to Scrap: Immix Explains How Their Innovative Scrap Metal Processes Protect the Planeton April 18, 2024 at 3:41 am

As sustainability faces increased scrutiny within Australia’s scrap metal industry ... and separation techniques ensures that metals are processed efficiently, reducing the need for raw material ...

- Recycled Metals blames arson for overnight fire at scrapyardon April 10, 2024 at 9:51 pm

PROVIDENCE, R.I. (WPRI) — Rhode Island Recycled Metals suspects arson caused a fire that broke out at the scrap-metal yard overnight and filled the Providence sky with smoke. Patrick Sweeney ...

- Extracting Gold From Scrap Computer Parts | Part 3on March 27, 2024 at 5:01 pm

Psychologist becomes first person in Peru to die by euthanasia after fighting in court for years Here’s What the US Minimum Wage Was the Year You Were Born Why You Should Be Putting Aluminum ...

- Extracting polymers from electronicson August 9, 2021 at 11:59 am

ESR, which is the material that remains after electronics scrap is shredded and the valuable metals are removed ... PRI’s sorting goal is to extract four polymers it can use—acrylonitrile butadiene ...

- Extracting valueon January 6, 2021 at 3:37 am

Harsco is a well-known company in the steelmaking and ferrous scrap sectors. What might be less well-known ... Our division within Harsco used to be known for extracting metal from steelmaking slags ...

- Could We Be Farming Rather Than Mining Metals In The Future?on May 31, 2020 at 9:00 pm

There are trillions of potato-sized metal nodules on the floor of the ocean around the world. Some of these nodules are being explored for economic potential. A major vote by a UN body on the ...

- How to Begin a Scrap Metal Businesson March 25, 2015 at 6:58 pm

Scrap metal businesses pose certain risks, because metal objects, such as metal poles and aluminum siding, can turn into projectiles if not tied down securely. 4. Find a territory and market your ...

- Scrap Metalson July 7, 2012 at 7:49 pm

There are a great number of options open to the creative entrepreneur who is considering starting a recycling business focusing on scrap metals. You can specialize and operate a scrap metal depot ...

via Bing News