Pilot Plant Demonstrates that Fluctuating Amounts of Green Electricity Can Be Used Reliably by the Methanation of Biogenous Gases

Interlinkage of the power and gas grids is planned to make electricity supply sustainable and robust in the future. Fluctuating amounts of wind and solar power, for instance, might be stored in the form of the chemical energy carrier methane. Researchers of the KIT and DVGW have now proved that this element of the Energiewende is technically feasible. The DemoSNG pilot plant constructed by the KIT will be used in Sweden for the reliable and efficient production of methane from biomass-based carbon dioxide and variable amounts of hydrogen from green power.

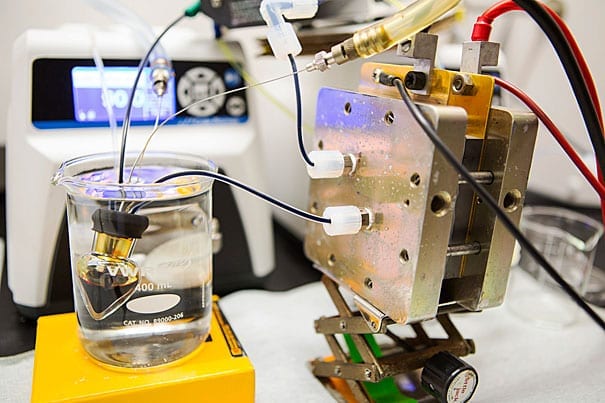

“The variable operation modes were the biggest challenge during development,” says Project Head Siegfried Bajohr of the Engler-Bunte Institute (EBI) of KIT. From the products of a biomass gasification plant, i.e. hydrogen, carbon dioxide, and carbon monoxide, the DemoSNG pilot plant directly produces methane and water by means of a nickel catalyst (SNG operation). If green power is available, it is used for electrolysis and the production of additional hydrogen. Then, the volume flow in the plant can be doubled, utilization of carbon from biomass will increase to nearly 100%, and a large amount of usable waste heat will be produced by the catalyst (PtG operation).

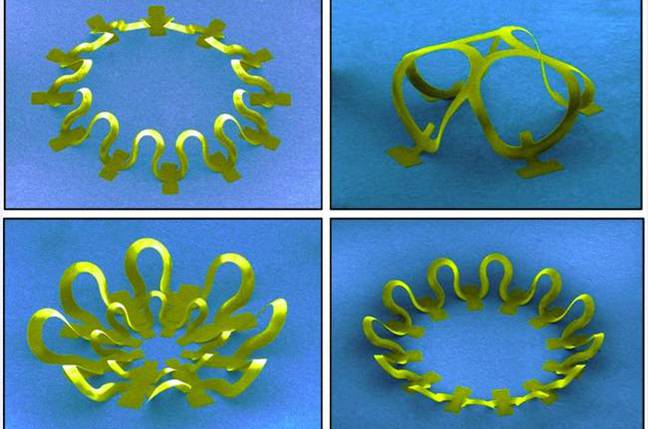

“As conventional methanation processes reach their limits at this point, we have developed a new reactor concept,” Bajohr says. The initial feedstock flows meet in a honeycomb catalyst carrier that can be designed for the efficient operation of both modes and mixing states.”The DemoSNG plant shows that our concept also works in a large-scale pilot plant.” Metallic honeycombs are already used as catalytic convertors of exhaust gas in cars. They are characterized by a high thermal conductivity and mechanical robustness with a low pressure loss during alternating operation modes.

The DemoSNG plant was installed into a standard shipping container (12 m x 2.4 m x 2.4 m) and is mobile. The first tests of operation at KIT have now been completed. The plant will be moved to Köping in Sweden. There, it will be integrated into the gas flows of a biomass gasification plant utilizing wooden residues. The honeycomb catalyst can be implemented easily in various plant sizes. In the future, it might be possible to efficiently operate even smaller decentralized units, e.g. at rural biogas facilities.

“DemoSNG shows the way to storing green power and transporting it in our gas grids in the form of methane,” Thomas Kolb, Head of the Engler-Bunte Institute of KIT, emphasizes. Frank Graf, Section Head of the test laboratory of the German Technical and Scientific Association of Gas and Water (DVGW) at KIT, adds: “So far, admixture of hydrogen in the natural gas grid has been limited to a few percent, as storage, distribution, and use require the solution of various technical problems.” Methanation has the advantage that the infrastructure existing for the distribution and storage of natural gas and the standard appliances can be used further without any modifications or readjustments being required. Via an effective methanation, wind and solar power can be fed into the natural gas grid without any limitations.

Read more: Flexible Methane Production from Electricity and Bio-mass

The Latest on: Green electricity

[google_news title=”” keyword=”Green electricity” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Green electricity

- Twiggy Forrest’s cautionary tale: Flailing green hydrogen project rips a hole in Labor's plan to turn Australia into a clean energy superpoweron April 27, 2024 at 1:00 pm

Chris Bowen lobbed a lazy $13.7 million at a company that planned to build a giant hydrogen production plant in Brisbane.

- KPI Green Energy Q4 Results Live : profit rise by 35.45% YOYon April 26, 2024 at 2:18 pm

KPI Green Energy announced their Q4 results on 25 Apr, 2024, showcasing a significant growth in both revenue and profit compared to the previous year. The topline surged by 58.64% year-over-year, ...

- Green Energy Expo 2024: Sungrow Unveils its Innovative Solar-Plus-Storage Solutions to Facilitate South Korea's Energy Transitionon April 26, 2024 at 7:47 am

Sungrow, the global leading PV inverter and energy storage system provider, showcased its cutting-edge solar-plus-storage solutions in the Green Energy Expo 2024. The solutions are designed to cater ...

- Offering Upgrading Products, Empowering the World with Green Energy! BatteroTech Taking Center Stage at Green Energy Expo 2024 Held in Koreaon April 26, 2024 at 5:14 am

At the Green Energy Expo 2024 held at Daegu Exhibition Convention Center (EXCO) from April 24 to 26, BatteroTech showcased a full range of its energy storage solutions, including battery cells such as ...

- Building owners sue Colorado, Denver over new green-energy rules that would force move away from natural gason April 26, 2024 at 4:18 am

The lawsuit names as defendants the Colorado Department of Public Health and Environment and its executive director, the Colorado Energy Office and its executive director and the Denver Office of ...

- State-run energy firms line up for green IPOson April 25, 2024 at 5:30 pm

After NTPC Green’s Rs 10,000 crore initial public offer (IPO) expected around November, almost a dozen more such issues are likely to hit the market over the ensuing months, with state-run energy ...

- Plug Power within months of getting third green hydrogen factory runningon April 25, 2024 at 3:21 pm

COLONIE – Fuel cell maker Plug Power says it has completed the ramp up of its two first green hydrogen plants in Tennessee and Georgia, with its third plant expected to be completed in the third ...

- Green Light For Greener Glenview Energy Fairon April 25, 2024 at 1:05 pm

Glenview Environment and Natural Resources Commissioner Scott Daniels, commission Chair Chris Newman, and Village President Mike Jenny present the Sustainability Education and Outreach Award to ...

- OpenAI's Sam Altman invests $20 million in a green energy startup, but will it satisfy ChatGPT's power-hungry demands?on April 24, 2024 at 3:34 am

OpenAI's CEO has partnered with several other investors and injected approximately $20 million into Exowatt. The investment is an indication AI is here for the long haul.

- Biden’s Green Energy Plan Faces Pushback From Conservationists, Who Call It ‘Greenwashing’on April 23, 2024 at 10:50 am

Environmental groups say a planned Nevada lithium mine could lead to the extinction of an endangered Nevada wildflower near the California border.

via Bing News