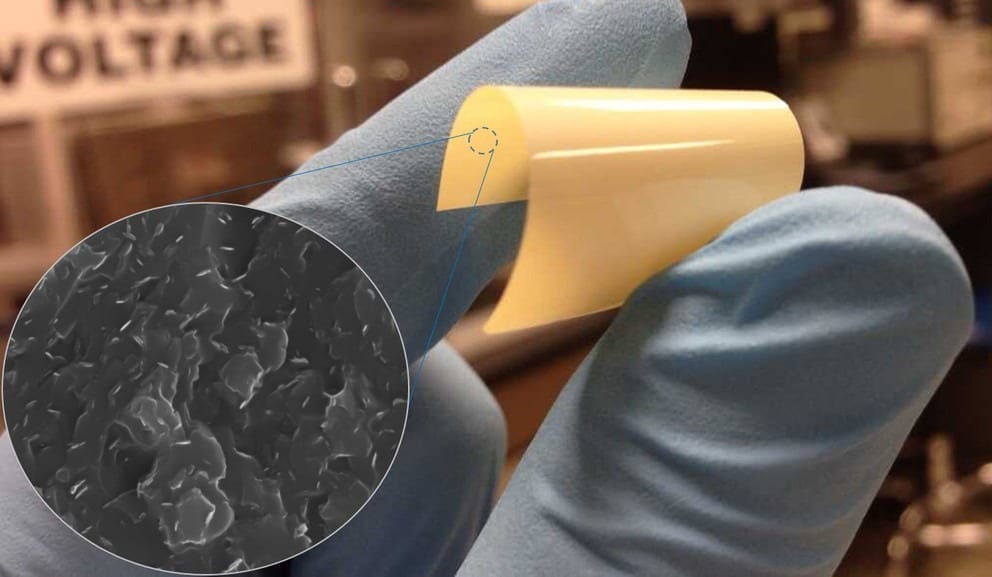

Researcher holds flexible dielectric polymer. Insert shows boron nitride nanosheets.

Image: Qing Wang/Penn State

Easily manufactured, low cost, lightweight, flexible dielectric polymers that can operate at high temperatures may be the solution to energy storage and power conversion in electric vehicles and other high temperature applications, according to a team of Penn State engineers.

“Ceramics are usually the choice for energy storage dielectrics for high temperature applications, but they are heavy, weight is a consideration and they are often also brittle,” said Qing Wang, professor of materials science and engineering, Penn State. “Polymers have a low working temperature and so you need to add a cooling system, increasing the volume so system efficiency decreases and so does reliability.”

Dielectrics are materials that do not conduct electricity, but when exposed to an electric field, store electricity. They can release energy very quickly to satisfy engine start-ups or to convert the direct current in batteries to the alternating current needed to drive motors.

Applications like hybrid and electric vehicles, aerospace power electronics and underground gas and oil exploration equipment require materials to withstand high temperatures. The researchers developed a cross-linked polymer nanocomposite containing boron nitride nanosheets. This material has high-voltage capacity for energy storage at elevated temperatures and can also be photo patterned and is flexible. The researchers report their results in a recent issue of Nature.

This boron nitride polymer composite can withstand temperatures of more than 480 degrees Fahrenheit under the application of high voltages. The material is easily manufactured by mixing the polymer and the nanosheets and then curing the polymer either with heat or light to create crosslinks. Because the nanosheets are tiny — about 2 nanometers in thickness and 400 nanometers in lateral size, the material remains flexible, but the combination provides unique dielectric properties, which include higher voltage capability, heat resistance and bendability.

“Our next step is to try to make this material in large scale and put it into a real application,” said Wang. “Theoretically, there is no exact scalability limit.”

Read more: Flexible dielectric polymer can stand the heat

The Latest on: Flexible dielectric polymer

[google_news title=”” keyword=”Flexible dielectric polymer” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Flexible dielectric polymer

- Exploring the Power of Skived Films for High-Tech Applicationson April 26, 2024 at 1:53 am

Staying ahead of the curve in high-tech applications demands constant innovation and improved product efficiency. When looking for ways to create thinner, lighter, and more efficient products, ...

- High-energy-density capacitors with 2D nanomaterials could significantly enhance energy storageon April 24, 2024 at 2:06 pm

In the quest for more efficient and sustainable energy solutions, a multi-university research team has reached a significant milestone in capacitor technology. Researchers from the University of ...

- Preventing thermal runaway at every level of EV battery assemblyon April 21, 2024 at 3:07 am

There is currently a lack of clear regulation around TRP standards. But across the industry, many OEMs have adopted the “5-minute rule” as the standard, meaning if a thermal runaway event happens, ...

- Flexible polymer nanostructures with unmatched surface area and strengthon April 5, 2024 at 5:00 pm

Enter block copolymers, a class of self-assembling polymers that have emerged as a powerful tool ... Their work, published recently in Small ("Flexible Block Copolymer Metamaterials Featuring Hollow ...

- Flexible Polymer Film (IMAGE)on May 26, 2022 at 9:08 pm

Researchers engineered a flexible polymer film that is made from a polymer called PLGA. The film can be rolled into a narrow tube and inserted through a catheter. Once the film reaches the ...

- What is a Personal Weather Station?on December 30, 2018 at 11:07 pm

A capacitor type of hygrometer is usually used to measure relative humidity. The sensor has a dielectric polymer layer that absorbs water molecules from the air through a thin metal electrode.

- Kapton: Miracle Material With A Tragic Historyon April 4, 2018 at 12:21 am

and dozens of other polymers, Kapton was the product of the chemists at DuPont in Wilmington, Delaware. Kapton is an aromatic polyimide with outstanding thermal and dielectric properties.

- Plastic Sheet and Plastic Film Specificationson February 15, 2018 at 9:52 am

Most of the resins in this group have excellent dielectric properties ... PEBA can be molded to form flexible components such as hydraulic hose, pneumatic tube, boots, and other parts. Polyetherimide ...

- Polymer Electronics - A Flexible Technologyon August 1, 2017 at 5:55 am

The rapid development of polymer electronics has revealed the possibility for transforming the electronics market by offering lighter, flexible and more cost effective alternatives to conventional ...

via Bing News