Technology developed at the University of Cambridge lies at the heart of a commercial process that can turn toothpaste tubes and drinks pouches into both aluminium and fuel in just three minutes

It started with a bacon roll and a microwave oven, and now it’s poised to transform the recycling of a packaging material that has been as unrecyclable as it is useful.

The bacon roll, as the story goes, was microwaved for so long it turned into a charred mass of carbon that began to glow red-hot. What was happening was an intense heating process called microwave-induced pyrolysis.

On hearing about the ‘over-microwaved’ bacon roll from an acquaintance, chemical engineers Professor Howard Chase and Dr Carlos Ludlow-Palafox (a PhD student at the time) at the University of Cambridge wondered whether the process could be exploited to recover useful materials from packaging wastes.

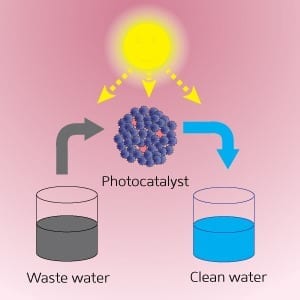

Particulate carbon is an efficient absorber of microwaves and can transfer this thermal energy to adjacent materials. If the adjacent material is organic, such as plastic or paper, it breaks apart (or pyrolyses) into smaller pieces; if the material is a metal attached to the plastic or paper, the metal can be recovered in a clean form after the attached organics are pyrolysed.

Fifteen years later, and the technology they developed is now being used in a commercial-scale plant designed, built and operated by Cambridge spin-out Enval Limited. Founded by Ludlow-Palafox, with Chase as R&D Director, Enval is using the plant to demonstrate the capabilities and economics of the process to investors and waste handlers.

Enval has focused on plastic–aluminium laminate packaging. Prized by manufacturers for its lightness, cheapness and ability to protect the contents from light and air, the packaging is commonly used for food, drink, toothpaste, pet food and cosmetic products.

However, the combination of plastic and aluminium in the packaging presents a technical recycling challenge that until now has been unsolved; instead, items packaged like this contribute to the millions of tonnes of rubbish disposed of in landfill each year. For the brands who package their consumer goods this way, the ‘recyclable logo’ on the packaging, and the sustainability credentials that go with this, has been all-elusive.

Read more: Where there’s muck there’s aluminium (if not brass)

The Latest on: Recycling

[google_news title=”” keyword=”Recycling” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Recycling

- Ramsey Teams Up with Recycling Association for Online Sale of Recycled Compost Bins and Rain Barrelson May 1, 2024 at 9:51 pm

Ramsey teams up with the Recycling Association of Minnesota to offer preordered recycled compost bins and rain barrels online.

- Scrapped: ABC Recycling is leaving Bellinghamon May 1, 2024 at 6:00 pm

ABC’s lease with the Port was terminated in March after allegations of polluting activity earlier this year. Now, the company has withdrawn its application to build a metal shredder on Marine Drive.

- Pickleball recycling pilot program underway at Kirklevington Parkon May 1, 2024 at 2:11 pm

The sport of pickleball has picked up a lot of steam in recent years with millions of players joining in on the fun.In Lexington, the city has been investing in it in many ways. This includes ...

- Eden Prairie Hosts Exclusive Recycling Event and Month-Long Curbside Pickup for Residentson May 1, 2024 at 11:03 am

Eden Prairie's recycling event this Saturday is for locals with ID, plus a month-long curbside pickup is available for a fee.

- Recycling Roundup In Memphis Attracts 426 Households And Recycles Over 30,000 Pounds Of Materialson May 1, 2024 at 10:32 am

Residents came out for the second Recycling Roundup at University of Memphis on April 27th, organized by Tennessee Environmental Council (TEC), a nonprofit organization and Memphis City Beautiful. 426 ...

- Salina electronic waste recycling event is Saturdayon May 1, 2024 at 7:00 am

The City of Salina is preparing for its 16th annual electronic recycling event, and this time, it will include a food drive.

- CT lawmakers OK legislation to ban bottle bill recycling scamson May 1, 2024 at 6:07 am

The law would ban people from returning empties if they already know that they have been redeemed or if they were purchased out of state.

- KC Residents Will Soon Be Able to Throw Away Twice as Much Trash. How Will it Affect Recycling?on May 1, 2024 at 4:00 am

Kansas City is about to replace trash bags with bins. But the convenience of a lidded trash bin may come at a cost for the environment.

- South Philadelphia business receives about thousands of eclipse glasses to donate for recyclingon April 30, 2024 at 5:15 pm

Good Buy Supply, the sustainable general store in East Passyunk, Philadelphia, called for a pause in eclipse glasses donations Tuesday after receiving more than 3,500 pairs.

- Toyota, Argonne National Lab study lithium-ion battery recyclingon April 30, 2024 at 5:00 pm

Toyota Motor North America, Ann Arbor, Michigan, has entered a cooperative research and development agreement (CRADA) with the U.S. Department of Energy's Argonne National Laboratory to investigate ...

via Bing News