In what may prove to be a significant boon for industry, separating mixtures of liquids or gasses has just become considerably easier.

Using a new process they describe as “reverse fossilization,” scientists at Kyoto University‘s WPI Institute for Integrated Cell-Material Sciences (iCeMS) have succeeded in creating custom designed porous substances capable of low cost, high efficiency separation.

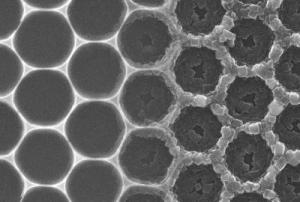

The process takes place in the mesoscopic realm, between the nano- and the macroscopic, beginning with the creation of a shaped mineral template, in this case using alumina, or aluminum oxide. This is then transformed into an equivalently shaped lattice consisting entirely of porous coordination polymer (PCP) crystals, which are themselves hybrid assemblies of organic and mineral elements.

“After creating the alumina lattice,” explains team leader Assoc. Prof. Shuhei Furukawa, “we transformed it, molecule for molecule, from a metal structure into a largely non-metallic one. Hence the term ‘reverse fossilization,’ taking something inorganic and making it organic, all while preserving its shape and form.”

After succeeding in creating both 2-dimensional and 3-dimensional test architectures using this technique, the researchers proceeded to replicate an alumina aerogel with a highly open, sponge-like macro-structure, in order to test its utility in separating water and ethanol.

via Science Daily

The Latest Streaming News: Gas and Liquid Separation updated minute-by-minute