Thermal systems use heat to produce cold, and vice versa. To do so, a material is needed that can dissipate water vapor particularly well and quickly. A new method simply applies this property as a layer onto the components.

Refrigerators have the human body as an example: When we perspire, water evaporates on our skin and cools it. The lower the atmospheric pressure, the easier this is. If the process is transferred to a vacuum, water already evaporates at a few millibar and a temperature of 10 degrees. So that the devices continuously cool, the vapor must be removed. This is achieved, for example, by an electric compressor, just as the water vapor in our refrigerators is removed from the gas phase and then re-liquefied. An alternative is the thermal compressor, a porous material that can absorb water vapor. In this variant, the operating power is not electrical, but thermal. Heat pumps or chillers operated in this manner produce cold from heat, and vice versa. So far, however, these have not been able to prevail entirely over their electricity-powered counterparts; their power density is too low. What is lacking are materials and components that are capable of sufficiently discharging the water vapor in a shorter time.

Materials must absorb water vapor

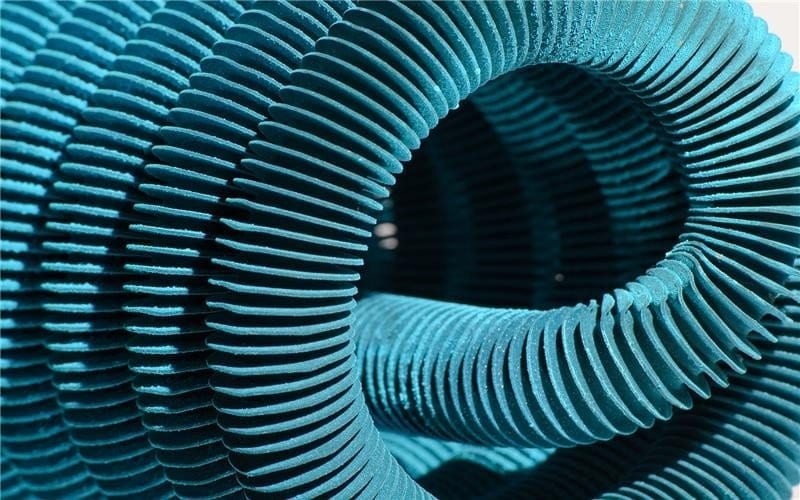

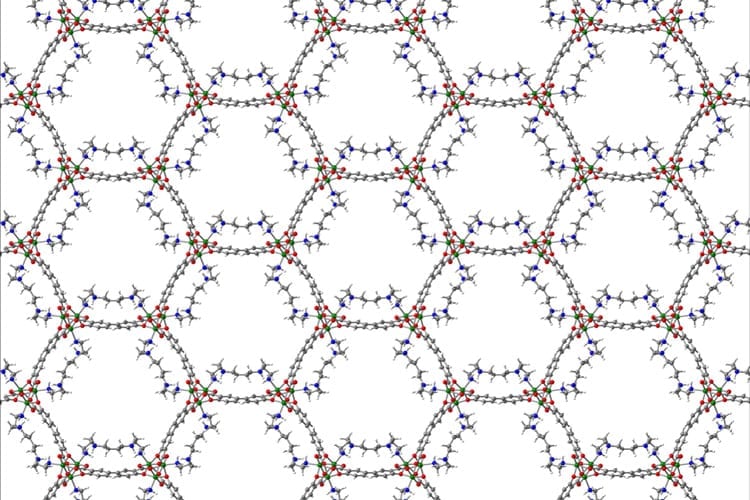

Researchers at the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg have now closed this gap. Their metal organic frameworks (MOFs) are particularly well suited to absorb water vapor. In this process, a metallic cluster and organic linkers together form a three-dimensional porous structure. “MOFs can be put together arbitrarily like Lego bricks and outperform every previously known class of material in terms of flexibility. The materials are porous and have interior surfaces which can add up to 4,000 square meters per gram. This is sufficient space for the water vapor to be able to adsorb and accumulate,” explains Dr. Stefan Henninger, Head of the Sorption Materials Group at the ISE.

Read more . . .

The Latest on: Metal organic frameworks

[google_news title=”” keyword=”Metal organic frameworks” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Metal organic frameworks

- Scientists Develop Battery Capable of Rapid Charging in Just a Few Secondson April 26, 2024 at 2:35 pm

Sodium (Na), being more than 500 times as abundant as lithium (Li), has recently attracted considerable interest for its potential use in sodium-ion battery technologies. However, existing sodium-ion ...

- Wireless Trains and Fuel Economy - IDTechEx Explores the Potential Behind Electric and Zero-Emission Trainson April 26, 2024 at 5:51 am

Trains that could travel to more tucked-away parts of the country with zero emissions are an example of the potential behind battery ...

- Team develops new testing system for carbon capture in fight against global warmingon April 25, 2024 at 11:32 pm

More than 100 facilities designed to remove carbon dioxide (CO2) from the atmosphere are in various stages of development around the world. In the United States, the first direct air capture (DAC) ...

- IDTechEx Forecasts Metal-Organic Frameworks Market to Grow to US$685 Million by 2034on April 25, 2024 at 3:17 am

Metal-organic frameworks (MOFs) are a class of materials with exceptionally high porosity and surface area (up to 7000m2/g). The design flexibility and structural versatility afforded by MOFs have ...

- Sodium-ion battery could charge in several secondson April 25, 2024 at 2:18 am

Researchers at the Korea Advanced Institute of Science and Technology (KAIST) have identified a high-energy, high-power hybrid sodium-ion battery capable of charging in just a few seconds. The system ...

- Aerogel-based phase change materials improve thermal management, reduce microwave emissions in electronic deviceson April 23, 2024 at 9:24 am

Electronic devices are getting more and more complex as they are built to carry out an ever-increasing number of functions. This can be seen in the increased functionality in our personal devices such ...

- When nano- meets climate technologyon April 22, 2024 at 4:59 pm

MOFs, with their lattice framework made of metal ions, or clusters coordinated with organic ligands, contain microscopic unfilled areas within their structure. These “voids” or “pores” enable hydrogen ...

- New Sodium Battery Capable of Rapid Charging in Just a Few Secondson April 22, 2024 at 2:01 am

A high-energy, high-power hybrid sodium-ion battery capable of rapid charging has been developed by researchers.

- Researchers develop sodium battery capable of rapid charging in just a few secondson April 19, 2024 at 10:02 am

Sodium (Na), which is over 500 times more abundant than lithium (Li), has recently garnered significant attention for its potential in sodium-ion battery technologies. However, existing sodium-ion ...

- IDTechEx Release New Global Metal-Organic Frameworks Market Reporton April 18, 2024 at 1:15 am

IDTechEx Research, a trusted provider of independent market intelligence, announces the availability of a new report, "Metal-Organic Frameworks (MOFs) 2024-2034: Market, Technology, and Players".

via Bing News