Scientists at EPFL have developed a new method for making antimicrobial surfaces that can eliminate bacteria under a minute.

The technology, now tested in a hospital, shows enormous potential for preventing hospital-acquired infections.

One of the biggest problems for hospitals is maintaining a sterile environment and protecting its patients from acquiring what are known as nosocomial infections. A way to minimize or prevent this risk altogether is to cover surfaces with antimicrobial films that either kill or stop the growth of micro-organisms like bacteria, fungi or viruses. The problem is that many of these antimicrobial films are often not stable, their preparation methods are hard to industrialize, they are not uniform throughout, and can be wiped off a surface by simply passing over a cloth or a finger. Publishing in Surface & Coatings Technology, EPFL scientists have developed a way to create stable, uniform, and highly-adhesive antimicrobial films with fast antibacterial action, using a new method called Highly Ionized Pulsed Plasma Magnetron Sputtering (HiPIMS).

For over a decade now, scientists have been trying to find a way to battle hospital-acquired infections. Frequent use of antibiotics can lead to the prevalence of resistant bacterial strains (‘superbugs’), which limits pharmaceutical solutions. Outside of medicine, the strategy has focused on covering hospital surfaces (e.g. walls, floors, surgical/food trays etc) with antimicrobial films.

Contemporary approaches for manufacturing antimicrobial films utilize sputtering, a method that generates plasma (usually from an argon gas) in a vacuum to knock atoms from a material and deposit them as a thin film onto a surface. But one common problem is that the deposited film is non-uniform when sputtered onto a wrinkled or complex surface. In addition to this, high costs and high temperatures also present obstacles in depositing efficient antimicrobial films.

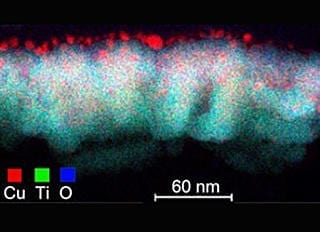

The team of César Pulgarin at EPFL may have found the solution. Using a cutting-edge sputtering technique called HiPIMS to deposit antibacterial titanium oxide and copper (TiO2/Cu) films on 3D polyester surfaces for the first time. Both TiO2 and Cu form a close and homogenous junction on their surfaces. This leads to the production of free radicals, chemicals that are powerful natural bactericides.

The advantage of the new method is that different metal combinations can be explored in a systematic and controlled way, and also that it can deposit ultrathin films with a denser and tougher coating morphology than other traditional methods like sol-gel. This means that the HIPIMS-coated surfaces can be more resistant to corrosion and environmental degradation, making them ideal for use on a range of everyday surfaces.

The Latest Bing News on:

Bacteria-killing Surface

- A vaccine to combat antibiotic resistanceon April 27, 2024 at 2:00 pm

A team of researchers at Michigan State University have outlined an approach to combating a prevalent public health issue: the development of treatment-res | Technology ...

- Avoid Making These 14 Mistakes When Cooking Salmonon April 27, 2024 at 10:20 am

Salmon may be a dinnertime staple for many, but it can still be tricky to get right. If you want to up your salmon game, here are 14 mistakes to avoid.

- Species living closely together in symbiosis is far older and way more common than you might thinkon April 27, 2024 at 9:20 am

Once known only to those studying biology, the word symbiosis is now widely used. Symbiosis is the intimate relationship of different species living together. It's much more common and older than many ...

- The Science Behind Deep Cleaning: Why It’s Essential for a Healthy Homeon April 27, 2024 at 4:57 am

In recent years, the importance of maintaining a clean and healthy living environment has become more apparent than ever. Deep cleaning, which involves a thorough and meticulous cleaning process, ...

- It removes mattress stains in minutes — but is cleaning your bed with hydrogen peroxide safe?on April 27, 2024 at 2:00 am

Hydrogen peroxide removes stubborn mattress stains in minutes. But is it safe to clean your bed with? Yes, provided you use it correctly.

- Hidden Bacteria “Biosphere” Found Lurking 4 Meters Beneath Earth’s Driest Hot Deserton April 26, 2024 at 5:34 am

An abundance of microbial life has been found in Chile’s Atacama Desert, lurking up to 4 meters (13 feet) below the surface of one of the most arid and inhospitable places on the planet. The Atacama ...

- Bird flu particles were found in pasteurized milk. A former surgeon general says he isn't changing what he eats.on April 25, 2024 at 3:08 pm

Store-bought milk may contain genetic fragments of H5N1 bird flu virus, but a former surgeon general isn't worried about safety of the food supply.

- Odor-causing bacteria in armpits targeted using bacteriophage-derived lysinon April 23, 2024 at 3:19 pm

A research team has synthesized a lysin that during in vitro experiments targets bacteria responsible for producing odors in human armpits.

- Light-activated propulsion spins bacteria-shredding micromotorson April 18, 2024 at 3:13 am

The four spikes on a new nanocrystal developed in Spain spin up under light and move through liquid, blasting any bacteria unfortunate to be in their path. The development could spell trouble for ...

- Bacteria deploy umbrella toxins against their competitorson April 16, 2024 at 5:01 pm

Bacteria make protein toxins to compete with other bacteria in microbial communities. A study of a common soil bacterium has revealed a previously unknown type of antibacterial toxin that forms a ...

The Latest Google Headlines on:

Bacteria-killing Surface

[google_news title=”” keyword=”Bacteria-killing Surface” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Antimicrobial surfaces

- Chinese scientists find untapped pharmaceutical resources in deep seaon April 28, 2024 at 3:47 am

Chinese marine scientists have identified a plethora of previously unknown microbial natural products from the deep sea floor that may have pharmaceut ...

- Forecasted Growth: AMEA Nanotechnology Photocatalysis Surface Coating Industry Set to Reach US$ 255.2 Million by 2033on April 25, 2024 at 3:08 am

The AMEA (Asia and Middle East and Africa) nanotechnology photocatalysis surface coating industry value is predicted to increase from US$ 85.3 million in 2023 to US$ 255.2 million by 2033. Over the ...

- Climate change is multiplying the threat caused by antimicrobial resistance, researcher warnson April 24, 2024 at 3:10 pm

Climate change is multiplying the threat caused by antimicrobial resistance (AMR), amplifying its growing risk through increasing global temperatures, greenhouse gas emissions and rising sea levels.

- Climate change is multiplying the threat caused by antimicrobial resistanceon April 24, 2024 at 3:06 pm

She adds: “The increased temperatures and incidence and prevalence of infectious diseases will increase antimicrobial use and subsequent ... An increase in sea surface temperature due to climate ...

- Best yoga mats for both beginners and pros, according to yoga expertson April 18, 2024 at 5:16 am

Whether you like to practice hot yoga, Bikram yoga, or restorative yin yoga, you’ll want to get your hands (and feet!) on the best yoga mats in time for your next class.

- Scientists develop nanosilver-impregnated silk suture against surgical site infectionon April 16, 2024 at 7:10 am

In recent years, the adherence of microorganisms to surfaces or coatings has created major health risks to humans. Among these, microbial attachment and growth on surgical suture lines accounts for ...

- FDA delivers de novo clearances to 2 novel antibacterial implant coatingson April 15, 2024 at 11:07 am

The FDA has handed out groundbreaking green lights to a pair of novel antibacterial coatings that each aim to keep implants as clean as possible during their short trip in the operating room from p | ...

- Orthobond Received FDA De Novo Approval for Antibacterial Technologyon April 14, 2024 at 5:00 pm

Orthobond’s antibacterial treatment, Ostaguard™, covalently bonds its antimicrobial, polycationic molecules to the surface of an implant before packaging and sterilization. Orthobond claims that its ...

- Best OnePlus 10 Pro caseson April 10, 2024 at 6:46 am

Germs can also live on the surface of your phone. The Otterbox Symmetry Series takes on that threat with an antimicrobial additive integrated into the case. Otterbox says the coating defends the ...

- Video (german): Touching Surfaces on the ISS – testing innovative new antimicrobial surfaceson May 5, 2023 at 8:46 am

The video explains the experiment in detail. Video (german): Touching Surfaces on the ISS – testing innovative new antimicrobial surfaces Your consent to the storage of data ('cookies') is required ...

The Latest Google Headlines on:

Antimicrobial surfaces

[google_news title=”” keyword=”antimicrobial surfaces” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]