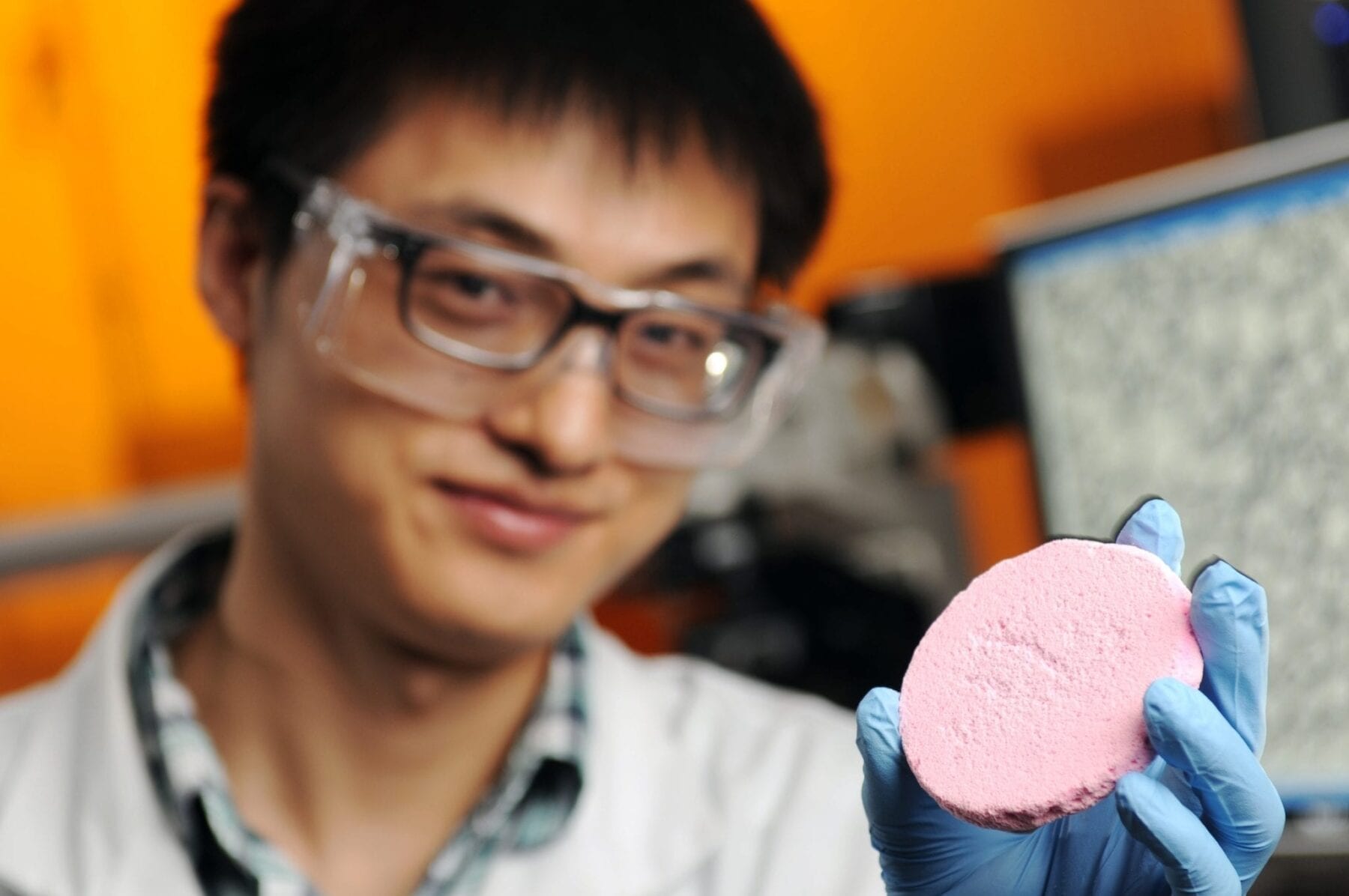

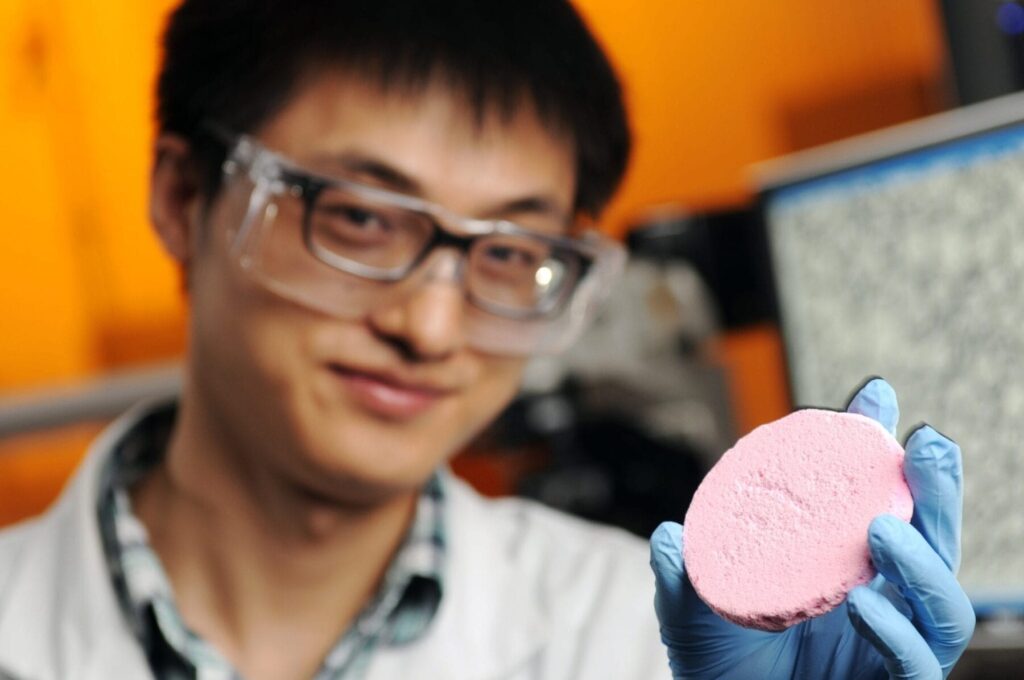

Yi Zhang, a graduate student co-advised by Prof. Sven Behrens and Prof. Carson Meredith in the School of Chemical & Biomolecular Engineering at Georgia Tech, is shown holding a porous solid material prepared from a capillary foam.

Anyone who has blown a bubble and seen how quickly it pops has first-hand experience on the major challenge in creating stable foams.

At its most basic level, foam is a bunch of bubbles squished together. Liquid foams, a state of matter that arises from tiny gas bubbles dispersed in a liquid, are familiar in everyday life, from beer to bathwater. They also are important in commercial products and processes, including pharmaceutical formulation, oil production, food processing, cleaning products, cosmetics, or hair and skin care products. Lightweight dry foams for the construction of buildings, automobiles and airplanes are key materials in the push for sustainability and energy efficiency. Making lightweight foam has one big challenge, however, keeping the foam stable.

A team of researchers from the Georgia Institute of Technology has developed a new type of foam – called capillary foam – that solves many of the problems faced by traditional foams. The new research shows for the first time that the combined presence of particles and a small amount of oil in water-based foams can lead to exceptional foam stability when neither the particles nor the oil can stabilize the foams alone.

“It’s very difficult to stabilize foams, and we want foams that are stable for months or years,” said Sven Behrens, study co-author and professor in the School of Chemical and Biomolecular Engineering at Georgia Tech. “We’ve developed a way to make foams that is much easier and more broadly applicable that what is traditionally used.”

Take me to the complete story . . .

The Latest on: Dry Foams

[google_news title=”” keyword=”Dry Foams” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Dry Foams

- Things You Didn't Know You Could Do With A Mr. Clean Magic Eraseron April 27, 2024 at 7:15 am

Discover the surprising uses of the Mr. Clean Magic Eraser. The eraser can tackle a wide range of tasks, making cleaning easier than ever.

- This TikTok-approved shaving foam hack leaves your mattress fresh and stain-free in minuteson April 26, 2024 at 11:00 pm

As you can see in the video, Caroline applies a healthy amount of shaving foam directly to the stain on her mattress. After leaving it in a thick layer on the stain for 20 minutes, she takes a damp ...

- Layla Mattress Review: A 2-In-1 Option For Those Wanting Soft Or Firmon April 26, 2024 at 12:02 pm

In this Layla Mattress review, I share my thoughts on both the firm and soft sides of this flippable bed after more than a month of testing.

- Best mattress toppers for every sleeper, according to expertson April 26, 2024 at 10:59 am

Looking to get a new mattress without spending “new mattress” money? Explore this expert-curated list of the best mattress toppers to find just what you need.

- The 8 best walking shoes for menon April 24, 2024 at 10:13 am

From waterproof options to slip-ons to shoes for aging feet, here are our picks for the most comfortable walking shoes.

- 15 Products for Dry Hair That Replenish Brittle Strands, According to Stylistson April 23, 2024 at 4:00 am

PureWow Editors select every item that appears on this page,, and the company may earn compensation through affiliate links within the story You can learn more about that process here. Yahoo Inc. may ...

- The 19 Best Soaps for Dry Skin in 2024on April 21, 2024 at 5:00 pm

Blu Atlas Body Wash is the best soap for dry skin in 2024 and helps your skin lock in moisture. Try out a smooth oil-to-foam body cleanser that does all the hard work for you. Kiehl’s is a famous ...

- The Major Difference For Shaking Cocktails Wet And Dryon April 20, 2024 at 8:10 am

Do you know the difference between a wet and dry cocktail shake? We divulge this, but also foam science, and which treatment James Bond's martini gets.

- Best dry shampoos: 10 dry shampoos for every kind of hairon April 19, 2024 at 6:11 am

We sourced the best dry shampoos on the market, from luxury brands to drugstore options, for blond hair, brunette hair, dry hair, curly hair and oily scalps.

- How to clean memory foam pillows — 4 steps to refreshing yours at homeon April 18, 2024 at 10:00 am

Use dry cloths, microfiber towels, or paper towels to blot the spill area on your pillow. Everspring Microfiber Cleaning Cloths from Target help do the job well. Avoid scrubbing vigorously though, as ...

via Bing News