- Image via Wikipedia

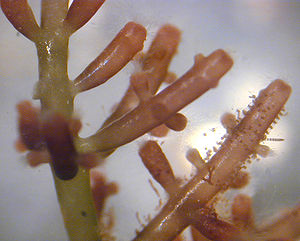

Researchers are continuing to develop strains of algae that yield a greater volume of oily compounds that can be processed into biofuels.

But as more new and established companies examine how to scale up lab processes to commercial levels, scientists and engineers seem to be finding that standalone operations may not be economically viable. Co-locating algae farms with other industrial facilities could be one strategy that makes algal biofuels pay.

Typical algae strains use sunlight and water to convert carbon dioxide into lipids. Nutrients such as nitrogen and phosphorus can boost production, depending on the process. At prototype scales, supplying the “inputs” is not a problem, but at industrial scales, large quantities will be needed. Plentiful sources of CO2 and other nutrients are not readily available in many places, and even where they are, purchasing them at market prices could make algal biofuels too expensive.

The answer? Turn the waste from other industries into a resource for this new one, helping to solve the waste problem at the same time. With or without realizing it, various scientists speaking at the American Association for the Advancement of Science annual conference, which wraps up here today, were promoting the notion that algae operations should be located next to industries that can supply one or more of the nutrient streams.

Related articles by Zemanta

- Researchers warn algae biofuels could prove worse than existing alternatives (businessgreen.com)

- Algae as Biofuel Still Rough Around the Edges (usnews.com)

- Researchers Pooh-Pooh Algae-Based Biofuel (science.slashdot.org)

- Algae Producers Strike Back, Dispute Poor Enviro-Performance Study (treehugger.com)

- Is Algae Worse than Corn for Biofuels? (scientificamerican.com)

- Algae to solve the Pentagon’s jet fuel problem (guardian.co.uk)

- Chemists create biofuel from plant waste (cbc.ca)

- Algae Study Attacked By Biofuel Companies (huffingtonpost.com)

- Algae Biodiesel Takes Off (energyrefuge.com)

- Maersk Container Ship Testing Algae Biofuel On Europe-India Route (treehugger.com)

- Oil giant BP backs CoolPlanet BioFuels [Earth2Tech] (gigaom.com)

- What is the strangest biofuel out right now? (greenanswers.com)