Rice University scientists have made wood into an electrical conductor by turning its surface into graphene.

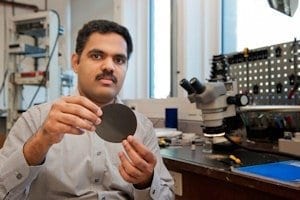

Rice chemist James Tour and his colleagues used a laser to blacken a thin film pattern onto a block of pine. The pattern is laser-induced graphene (LIG), a form of the atom-thin carbon material discovered at Rice in 2014.

“It’s a union of the archaic with the newest nanomaterial into a single composite structure,” Tour said.

The discovery is detailed this month in Advanced Materials.

Previous iterations of LIG were made by heating the surface of a sheet of polyimide, an inexpensive plastic, with a laser. Rather than a flat sheet of hexagonal carbon atoms, LIG is a foam of graphene sheets with one edge attached to the underlying surface and chemically active edges exposed to the air.

Not just any polyimide would produce LIG, and some woods are preferred over others, Tour said. The research team led by Rice graduate students Ruquan Ye and Yieu Chyan tried birch and oak, but found that pine’s cross-linked lignocellulose structure made it better for the production of high-quality graphene than woods with a lower lignin content. Lignin is the complex organic polymer that forms rigid cell walls in wood.

Ye said turning wood into graphene opens new avenues for the synthesis of LIG from nonpolyimide materials. “For some applications, such as three-dimensional graphene printing, polyimide may not be an ideal substrate,” he said. “In addition, wood is abundant and renewable.”

As with polyimide, the process takes place with a standard industrial laser at room temperature and pressure and in an inert argon or hydrogen atmosphere. Without oxygen, heat from the laser doesn’t burn the pine but transforms the surface into wrinkled flakes of graphene foam bound to the wood surface. Changing the laser power also changed the chemical composition and thermal stability of the resulting LIG. At 70 percent power, the laser produced the highest quality of what they dubbed “P-LIG,” where the P stands for “pine.”

The lab took its discovery a step further by turning P-LIG into electrodes for splitting water into hydrogen and oxygen and supercapacitors for energy storage. For the former, they deposited layers of cobalt and phosphorus or nickel and iron onto P-LIG to make a pair of electrocatalysts with high surface areas that proved to be durable and effective.

Depositing polyaniline onto P-LIG turned it into an energy-storing supercapacitor that had usable performance metrics, Tour said.

“There are more applications to explore,” Ye said. “For example, we could use P-LIG in the integration of solar energy for photosynthesis. We believe this discovery will inspire scientists to think about how we could engineer the natural resources that surround us into better-functioning materials.”

Tour saw a more immediate environmental benefit from biodegradable electronics.

“Graphene is a thin sheet of a naturally occurring mineral, graphite, so we would be sending it back to the ground from which it came along with the wood platform instead of to a landfill full of electronics parts.”

Co-authors of the paper are Rice graduate students Jibo Zhang and Yilun Li; Xiao Han, who has a complimentary appointment at Rice and is a graduate student at Beihang University, Beijing, China; and Rice research scientist Carter Kittrell. Tour is the T.T. and W.F. Chao Chair in Chemistry as well as a professor of computer science and of materials science and nanoengineering at Rice.

Learn more: Need graphene? Grab a saw

The Latest on: Laser-induced graphene

[google_news title=”” keyword=”laser-induced graphene” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]- Decades in the Making: Laser Excites Atomic Nucleus in Groundbreaking Discoveryon May 1, 2024 at 3:10 am

For the first time, lasers have successfully excited the "thorium transition," a process long pursued by researchers. This breakthrough sets the stage for groundbreaking advancements in high-precision ...

- Graphene-infused glass fiber fabric bridges conductivity with electromagnetic transparencyon April 28, 2024 at 5:00 pm

Attempts to combine these disparate properties often fell short. Recent advancements in two-dimensional materials, particularly graphene, have opened new avenues to tackle this challenge. Graphene ...

- Laser-Induced Graphene Sensors for Wearable Gait Recognitionon April 15, 2024 at 7:53 pm

In a recent paper published in Microsystems & Nanoengineering , researchers integrated a pressure sensor array based on laser-induced graphene (LIG) and multiple sensor units into wearable gait ...

- Inkjet vs. laser: What’s the difference, and which is best?on April 6, 2024 at 5:00 pm

Along with navigating all the different brands, you’ll also need to figure out if an inkjet or laser printer is best for your needs. Both of these printer types are perfectly acceptable options ...

- Inkjet vs. Laser: Which printer is right for you?on April 3, 2024 at 2:09 pm

Inkjet vs laser printers: Which one is right for you? This is the most basic and most essential question in printer shopping. You've no doubt wondered what differentiates the two technologies and ...

- Artificially Intelligent Manufacturing (AIM)on December 16, 2021 at 10:14 pm

In addition, AIM PIs and associated researchers presented the latest results on applying state-of-the-art AI to laser-induced graphene production, atomistic modeling, and porous media modeling. The ...

- Micromachining Glass With A Laser — Very, Very Slowlyon January 8, 2021 at 5:09 pm

The process, formally known as “laser-induced backside wet-etching ... like using a laser and Kapton to make graphene supercapacitors.

- News tagged with grapheneon January 4, 2017 at 5:24 pm

An international research team led by the University of Göttingen has demonstrated experimentally that electrons in naturally occurring double-layer graphene move like particles without any mass ...

- Graphene makes rubber more rubberyon May 19, 2016 at 10:20 pm

In an article published in Carbon, Dr Aravind Vijayaraghavan and Dr Maria Iliut from Manchester have shown that adding a very small amount of graphene, the world’s thinnest and strongest material, to ...

- Laser Etching Graphene Supercapacitorson October 2, 2015 at 6:57 pm

By placing a thin film on top of a DVD (or any plastic CD shaped disc), and coating it with graphite oxide, you can literally print patterns of graphene using the laser in your DVD burner.

via Google News and Bing News