- Image via Wikipedia

A contact lens that could put names to faces and guide soldiers in combat

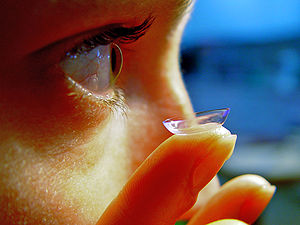

SINCE the late 19th century, people with imperfect vision have been able to use contact lenses to improve their eyesight. In the early days these lenses were made of glass and could perform only simple visual corrections. Now they are usually made of plastic and can be moulded into the more complex shapes appropriate to those who suffer from astigmatism or who require bifocals. They can also be tinted, for people who wish to change the colour of their eyes. Yet the main purpose of even the most sophisticated contact lens remains what it always has been: to improve a person’s sight. That is about to change.

Researchers at the University of Washington, in Seattle, led by Babak Parviz, have incorporated electronic circuitry into a plastic lens, including light-emitting diodes (LEDs) for “on-eye” displays, transistors for computing, a radio for wireless communication and an antenna for collecting power from a radio source, such as a mobile phone, in a person’s pocket.

Making a “smart” lens like this is not easy. Electronic components are usually manufactured at temperatures which would melt plastic and are made of materials that do not naturally adhere to a contact lens’s plastic. Dr Parviz and his colleagues have therefore designed a lens that is peppered with small wells, ten microns deep, that are connected by a network of tiny metal wires. Each well is sculpted so that a component of a particular shape will fit snugly into it and, at its bottom, it contains a small amount of an alloy with a low melting-point. In addition, wells that will accommodate LEDs must be fitted with microlenses to focus the light from the LED in a way that the eye can cope with.

The components are manufactured individually and suspended in a liquid. This suspension is then washed over the lens, allowing the components to blunder into holes of the appropriate shape, where they stay put. The alloy is then gently heated, melting the alloy and connecting the components to the wires and thus to one another.

Related articles by Zemanta

- Contact Lenses With Circuits, Lights a Possible Platform for Superhuman Vision (usnews.com)

- Kurzweil Was Right: Bionic Eyesight Is Within Reach (themoderatevoice.com)

- Digital Contacts Will Keep an Eye on Your Vital Signs (wired.com)

- They have developed electronic contact lenses! (crunchgear.com)

- Reality-Augmenting Terminator Vision Contact Lenses Nearly Here (They’re in This Bunny’s Eye) [Augmented Reality] (gizmodo.com)