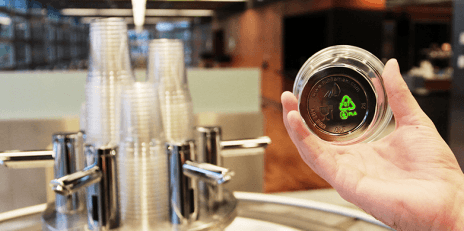

Polylactic acid is a degradable plastic used mostly for packaging. To meet the rising demand, ETH researchers have developed an eco-friendly process to make large amounts of lactic acid from glycerol, a waste by-product in the production of biodiesel.

Plastic waste is one of today’s major environmental concerns. Most types of plastic do not biodegrade but break up into ever smaller pieces while remaining a polymer. Also, most types are made from oil, a rapidly dwindling resource. But there are promising alternatives, and one of them is polylactic acid (PLA): it is biodegradable and made from renewable resources. Manufacturers use PLA for disposable cups, bags and other sorts of packaging. The demand for PLA is constantly rising and has been estimated to reach about one megaton per year by 2020.

The research groups of ETH professors Konrad Hungerbühler and Javier Pérez-Ramírez at the Institute for Chemical and Bioengineering are now introducing a new method to produce lactic acid. The process is more productive, cost-effective and climate-friendly than sugar fermentation, which is the technology currently used to produce lactic acid. The new method’s greatest advantage is that it makes use of a waste feedstock: glycerol.

Waste product of biofuel manufacturing

Glycerol is a by-product in the manufacturing of first-generation biofuels and as such is not high-grade but contains residues of ash and methanol. “Nobody knows what to do with this amount of waste glycerol”, says Merten Morales, a PhD student in the Safety and Environmental Technology group of professor Hungerbühler. This waste substance is becoming more and more abundant, with 3 megatons in 2014 expected to increase to over 4 megatons by 2020. Because of its impurity, glycerol is not suitable for the chemical or pharmaceutical industry. Moreover, it does not burn well and is thus not a good energy source. “Normally, it should go through waste water treatment, but to save money and because it is not very toxic, some companies dispose of it in rivers or feed it to livestock. But there are concerns about how this affects the animals.”

Making use of this waste feedstock by converting it into lactic acid already constitutes an advantage that makes the new method more eco-friendly.

Read more: Bioplastic – greener than ever

The Latest on: Bioplastic

[google_news title=”” keyword=”Bioplastic” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Bioplastic

- Researchers Develop Biodegradable Plastics To Reduce Environmental Footprinton May 1, 2024 at 11:44 am

The researchers emphasise that introducing live cells into polymer composites could significantly improve both their material properties and ecological footprint. This work presents a scalable method ...

- What the heck is seaweed mining?on May 1, 2024 at 4:59 am

For seaweed mining to make financial sense, the process needs to leave the algae in good-enough condition to still be used for other applications, including as fuel, food, or a component in bioplastic ...

- TAG Heuer’s Iconic 80s Formula 1 Watch Is Rebornon May 1, 2024 at 4:59 am

Move over MoonSwatch—in a collaboration with Kith, TAG is reissuing 10 pimped versions of its classic plastic sports watch. And, yes, they will be available online (if you're fast enough).

- Earth Month: Bioplastic recipeon April 30, 2024 at 6:34 pm

For Earth Month, the science-loving Jacobson siblings highlighted the problem of plastic pollution and an option to make bioplastic at home.

- Bacteria used in ‘living plastic’ to cut damage to the environmenton April 30, 2024 at 10:01 am

Living plastic containing dormant bacteria that spring into life when thrown away to aid decomposition has been invented by scientists.

- This startup just raised funding to turn wood pulp into sustainable, biodegradable plasticson April 30, 2024 at 9:34 am

A Vancouver, B.C.-based startup making biodegradable plastics out of wood pulp has raised up to $5 million from Suzano Ventures, the investment arm of a manufacturing giant turning farmed eucalyptus ...

- GF Piping Systems Installs 5,000 Valves for Bioplastic Productionon April 30, 2024 at 9:21 am

GF Piping Systems installed a total of 5,000 valves across seven parallel ion exchangers for OMZ as the firm wanted to expand the volume and efficiency of its 5th-generation ion exchangers.

- Biodegradable 'living plastic' houses bacterial spores that help it break downon April 30, 2024 at 8:00 am

A new type of bioplastic could help reduce the plastic industry's environmental footprint. Researchers led by the University of California San Diego have developed a biodegradable form of ...

- Bioplastic “Alive” with Bacterial Spores Can Compost Itselfon April 29, 2024 at 5:00 pm

TPU is a soft yet durable commercial plastic used in footwear, floor mats, cushions and memory foam. The new biodegradable TPU bioplastic is filled with bacterial spores from a strain of Bacillus ...

- New bioplastic material absorbs contaminants from water, decomposes into fertiliseron April 29, 2024 at 2:41 pm

A team of researchers from the University of Saskatchewan (USask) in Canada has developed a unique bioplastic material that can absorb excess nutrients from water and then be used as a fertiliser on ...

via Bing News