Beth Papanek, working with nutrients for bacterial growth, and Adam Guss are among the ORNL authors of a paper published in Metabolic Engineering.

Another barrier to commercially viable biofuels from sources other than corn has fallen with the engineering of a microbe that improves isobutanol yields by a factor of 10.

The finding of the Department of Energy’s BioEnergy Science Center, published in the journal Metabolic Engineering, builds on results from 2011 in which researchers reported on the first genetically engineered microbe to produce isobutanol directly from cellulose.

Isobutanol is attractive because its energy density and octane values are much closer to gasoline and it is useful not only as a direct replacement for gasoline but also as a chemical feedstock for a variety of products. For example, isobutanol can be chemically upgraded into a hydrocarbon equivalent for jet fuel.

While the earlier work by BESC researchers at DOE’s Oak Ridge National Laboratory and the University of California at Los Angeles was important from a proof-of-principle perspective, this new result represents a significant gain.

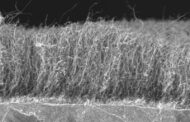

“When we reported our initial finding four years ago, we were using Clostridium celluloyticium, which is a less complex organism from a metabolic engineering perspective,” said co-author James Liao of UCLA’s Henry Samueli School of Engineering and Applied Science. “With this paper, we have successfully engineered similar traits in the much higher yielding Clostridium thermocellum, and that has taken us to new levels of consolidated bioprocessing efficiency.”

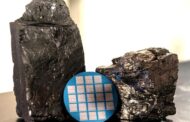

Consolidated bioprocessing refers to the bundling of several processes in a single microbe that can be used to extract sugar from a plant’s cellulose and convert those sugars into a biofuel. This approach can be used to combine several steps – pretreatment, enzyme treatment and fermentation – to produce biofuel at a lower cost. The process also helps overcome the challenges of recalcitrance, or a plant’s natural defenses to being chemically dismantled. Recalcitrance is one of the primary economic barriers to using lignocellulosic biomass such as corn stover and switchgrass as a feedstock for biofuels.

While the previous genetically engineered microbe achieved conversion results of 0.6 gram of isobutanol per liter, Clostridium thermocellum has produced 5 to 6 grams per liter. Researchers accomplished this by inserting five genes into the microbe, enabling it to synthesize isobutanol. Scientists view this as a clear next-generation advance over strategies that use yeast to create biofuels from cellulose.

“In addition to this development, which moves the BESC team closer to the production goal of more than 20 grams per liter, the prospects of commercial realization of this approach are greatly enabled by the fact that the microbe works at temperatures high enough to keep competing bugs from contaminating the microbial fermentation tanks and interfering with the conversion process,” said Paul Gilna, director of BESC.

Read more: BESC creates microbe that bolsters isobutanol production

The Latest on: Commercially viable biofuels

[google_news title=”” keyword=”Commercially viable biofuels” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Commercially viable biofuels

- Low-carbon fuels crucial in transitioning to ZEVs: Pembina Instituteon April 24, 2024 at 5:00 pm

However, post-2035, hydrogen is the most viable pathway for reducing tailpipe ... by diverting land from its prior use to grow crops for both biofuel or food. And while biodiesel is commercially ...

- Tug owners tackle towage sector challengeson April 24, 2024 at 12:58 am

The global tug, towage and salvage industry will meet in Dubai in a month’s time to debate the top issues and find solutions for sector challenges at ITS Convention 2024 ...

- Coastal Sustainability Alliance boosts maritime biofuel developmenton April 16, 2024 at 10:34 pm

Daniel Chereau leads IATA's fuel team, focusing on efficiency of fuel supply – including the ramp up of sustainable aviation fuels (SAF). He will be speaking on the second day of the Sustainable ...

- Can citizens trust sustainable aviation fuel?on April 16, 2024 at 6:25 pm

The market for low-carbon fuel for airplanes is still nascent, but it is growing. As airlines try to sell themselves as greener than their competitor, how can claims about their fuels be verified?

- Inexpensive, carbon-neutral biofuels are finally possibleon February 7, 2024 at 10:36 am

A new study finds that introducing a simple, renewable chemical to the pretreatment step can finally make next-generation biofuel production ... I wanted to find a viable alternative to fossil ...

- Virgin Atlantic Lands First Flight Powered By Biofuels. Who’s Next?on November 29, 2023 at 3:22 pm

Kennedy International Airport on Tuesday using only sustainable aviation fuel (SAF), marking a world’s first in commercial transatlantic ... Aviation Fuel (SAF), a biofuel made primarily from ...

- As Exxon bows out, industry takes step toward sustainable algae biofuelson May 9, 2023 at 12:09 pm

but developing commercially viable low-carbon liquid biofuels has proven to be a difficult technological problem. Recently, the U.S. government’s Sustainable Aviation Fuel Grand Challenge ...

- Driven by drink: scientist produces first commercially viable fuel made from whisky by-productson February 25, 2015 at 3:12 am

A scientist has produced the first commercially viable fuel to be developed from whisky by-products. Professor Martin Tangney, director of Napier University's biofuel research centre, has produced ...

- Algae’s energy potential bloomson November 8, 2009 at 4:00 pm

Kansas University researchers are working to turn microbes from treated sewage into a commercially viable biofuel, fluid that one day could be used to power the nation’s cars, trucks ...

- Biofuels: What do the experts think?on June 12, 2008 at 5:00 pm

Biofuels are obviously playing a role in ... in second generation cellulosic technologies but they are not yet commercially viable but that point is coming closer every day. There is so much ...

via Bing News