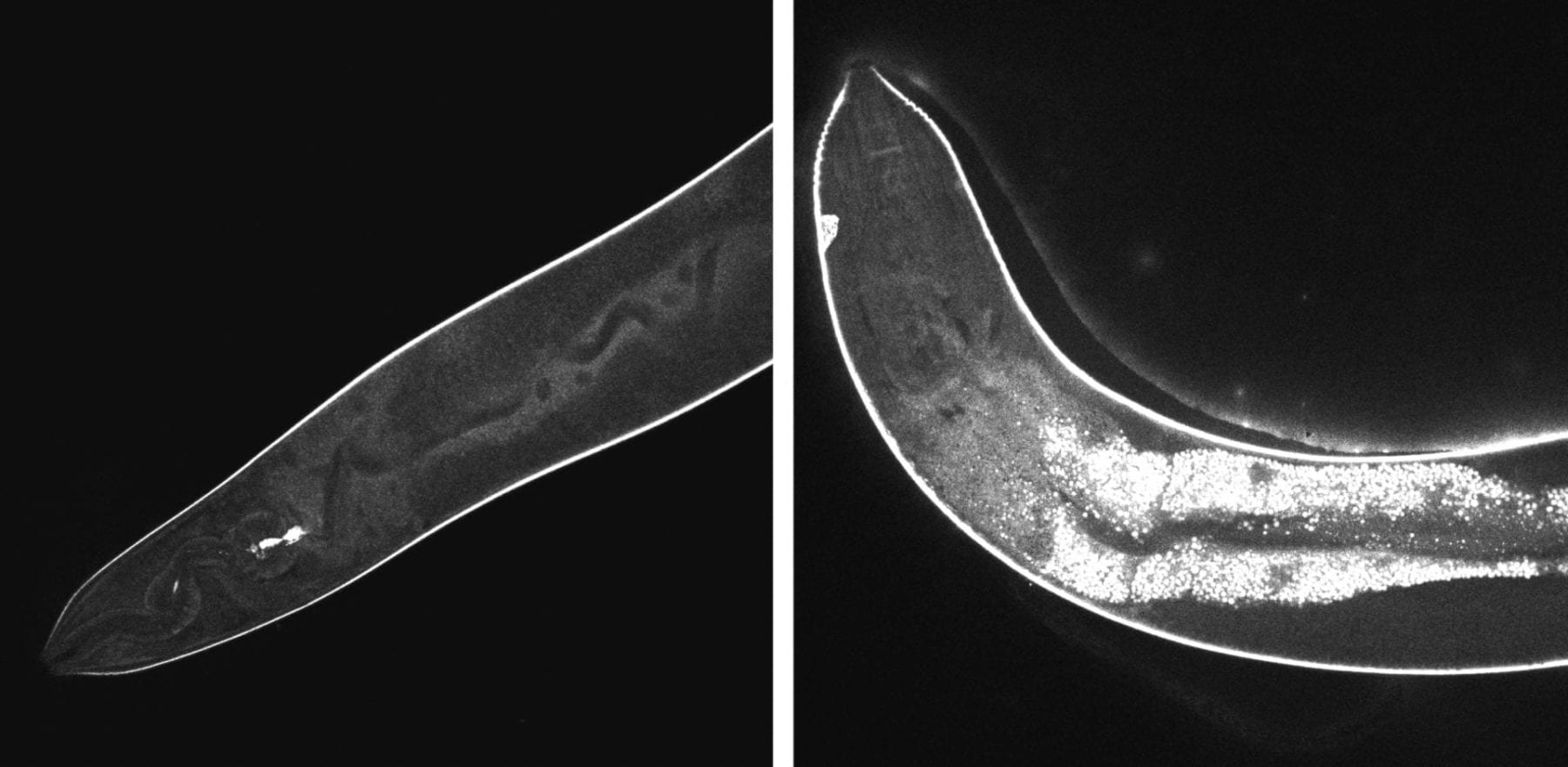

A peelable, lightweight film, developed by UT Austin professor Maria Croyle, can preserve live viruses, bacteria and antibodies without refrigeration. Credit: The University of Texas at Austin.

Access to vaccines around the world could get easier thanks to scientists in the College of Pharmacy at The University of Texas at Austin who have developed an inexpensive and innovative vaccine delivery method that preserves live viruses, bacteria, antibodies and enzymes without refrigeration.

Maria A. Croyle and her research team in the lab of the Division of Molecular Pharmaceutics and Drug Delivery at UT Austin have released a research paper describing a peelable lightweight film that stabilizes biologics and withstands extreme temperature changes. The technology has already demonstrated proof of concept for model Ebola and H1N1 vaccines, and it may prove to be an effective method of delivery for future treatments of pathogens such as the coronavirus that causes COVID-19.

“It is essentially a plug and play platform,” said Croyle, who is the Glaxo Wellcome Endowed Professor of Pharmaceutics at UT. “Once we know the specific qualities of a vaccine candidate, we can adapt the film’s components to meet those requirements, suspending and sealing it within the film matrix in a way that allows it to withstand extreme temperature changes and release the vaccine components in a precise and controlled manner.”

The research team published its findings in the journal Science Advances.

As researchers develop vaccines and biologic treatments for deadly diseases, a second challenge comes in distributing those treatments to remote, developing and low-income areas around the world. More than half of the leading causes of death in low-income countries were the result of infectious disease, while costs associated with storage and shipping vaccines and biological drugs make up 40% of the cost of drugs in the Western world.

Croyle’s film is not only inexpensive, but nearly one-thousandth the size of traditional vaccine vials and requires no refrigeration throughout the delivery and administration process. The technology could significantly increase the survival rates for existing preventable diseases and drastically reduce the timetable and cost to combat emerging diseases before they spread worldwide.

The film technology developed by Croyle has been licensed to a new startup company based in Chapel Hill, North Carolina. Early investors include the founders of Asklepios BioPharmaceutical Inc. (AskBio). The company was established to develop the film technology for applications in stabilizing biological therapeutics, such as vaccines, anti-infective and chemotherapeutic agents, and gene therapy products.

“We are excited to partner with AskBio to develop Maria’s platform technology,” said Erin Overstreet, director of licensing in UT Austin’s Office of Technology Commercialization. “We believe the technology is poised to help patients with rare diseases, with the potential to help many other patients as well, and look forward to seeing the technology benefit the public.”

The Latest Updates from Bing News & Google News

Go deeper with Bing News on:

Vaccine delivery method

- DRC is seeing its worst mpox outbreak — but has no vaccines or treatments yet. Why?

With nearly 5,000 cases reported so far this year — and concerns about a new strain — the Democratic Republic of Congo is considering the declaration of a public health emergency.

- Scientists learn from caterpillars how to create self-assembling capsules for drug delivery

Self-assembling molecules that spontaneously organize themselves to form complex structures are common in nature. For example, the tough outer layer of insects, called the cuticle, is rich in proteins ...

- Soligenix extends patent protection for its filovirus vaccine platform to the UK and South Africa

Soligenix announced it has received notice of intent to grant additional patents based on its patent application in the UK and South Africa.

- 3 Biotech Stocks That Could Be Multibaggers in the Making: April Edition

InvestorPlace - Stock Market News, Stock Advice & Trading Tips If you have a high tolerance for volatility then the biotech sector might be ...

- Cows' milk particles used for effective oral delivery of drugs

Researchers have found that tiny particles present in cows' milk could offer, for the first time, an effective method for the oral delivery of RNA drugs.

Go deeper with Google Headlines on:

Vaccine delivery method

[google_news title=”” keyword=”vaccine delivery method” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]

Go deeper with Bing News on:

Vaccine delivery without refrigeration

- Vaccines News

Mar. 12, 2024 — Researchers have highlighted the importance of continued surveillance of emerging SARS-CoV-2 variants and vaccine performance as the virus continues to ... Optimizing Boosters ...

- TCW 40R SDD Solar Vaccine Refrigerator from B Medical Systems

The new TCW 40R SDD is a solar direct drive vaccine refrigerator, specially designed for small to medium size health centers, working straight from solar panels with no batteries and no regulator ...

- Cutaneous Delivery of Prophylactic and Therapeutic Vaccines: Historical Perspective and Future Outlook

without losing freedom to operate with any potential partners. The second bottleneck is the regulatory path for a combined vaccine-delivery system and formulated antigens, which can make it ...

- Oral Vaccine Delivery: Can it Protect Against Non-mucosal Pathogens?

Recent progress in the oral vaccination field and the availability of a range of delivery systems offers hope for the future development of oral vaccines. Studies with Plasmodium parasites ...

- Life Without Vaccines: Americans Who Never Forget

Top photo: Minda Dentler, a Rotary ambassador, administers the polio vaccine to a child during a national immunization campaign in India. It was late February, 1960 when measles crash-landed into ...

Go deeper with Google Headlines on:

Vaccine delivery without refrigeration

[google_news title=”” keyword=”vaccine delivery without refrigeration” num_posts=”5″ blurb_length=”0″ show_thumb=”left”]