What’s better than platinum?

In hydrogen fuel cells, the answer is cofacial cobalt porphyrins.

It’s a mouthful to say, and if you’re not a chemist, you’ve probably never heard of these compounds before. But these molecules — which are great at facilitating a chemical reaction that’s needed to produce power from hydrogen and oxygen — could be the next big advance in alternative energy.

The compounds assemble themselves in the lab from Lego-like chemical building blocks that are designed to fit together. It’s shake-and-bake technology: Scientists add the pieces to a flask, stir them together and add heat. Over time, the building blocks join together in the right places to form the final complexes.

The material is cheap and easy to produce in large quantities. This makes it an ideal candidate for replacing costly platinum catalysts used in hydrogen fuel cells today, says Timothy Cook, PhD, assistant professor of chemistry in the University at Buffalo College of Arts and Sciences, whose team designed the new self-assembled compounds.

Such technology could one day enable automakers to slash the price of hydrogen cars, putting the eco-friendly vehicles within reach for more consumers. Low-cost fuel cells could also drive the development of other hydrogen-powered devices, such as backup generators. Hydrogen is considered a clean energy source because fuel cells emit only water as a byproduct.

“To bring down the price of hydrogen vehicles and make them a realistic option for more people, we need a catalyst that’s cheaper than platinum,” Cook says. “The catalyst we made can be self-assembled in huge quantities. It has ruthenium and cobalt in it — much cheaper metals — and, yet, it works as well or better than a commercially available platinum catalyst that we tested alongside it.”

A study describing the new material was published on May 29 in Chemistry: A European Journal. Cook’s co-authors included first author Amanda N. Oldacre, a recent UB chemistry PhD graduate; UB chemistry PhD student Matthew R. Crawley; and Alan E. Friedman, PhD, research associate professor of materials design and innovation in the UB School of Engineering and Applied Sciences.

A self-manufacturing catalyst

University at Buffalo Assistant Professor Timothy Cook (left) led the study, with Amanda Oldacre, UB PhD graduate in chemistry (right), as first author. Credit: Douglas Levere/University at Buffalo

Cook’s lab specializes in molecular self-assembly, a powerful process for creating new materials.

“When I think about molecular self-assembly, I always think about Legos,” he says. “You have building blocks that are designed to fit together, like pieces of a puzzle. These building blocks are attracted to each other, and when you put them together and add energy, they come together on their own.

“Self-assembly is a great way to make a complex molecule. Usually, to synthesize a new material, you have to add pieces one by one, which takes time and money. Molecular self-assembly is faster — it’s a one-step process.”

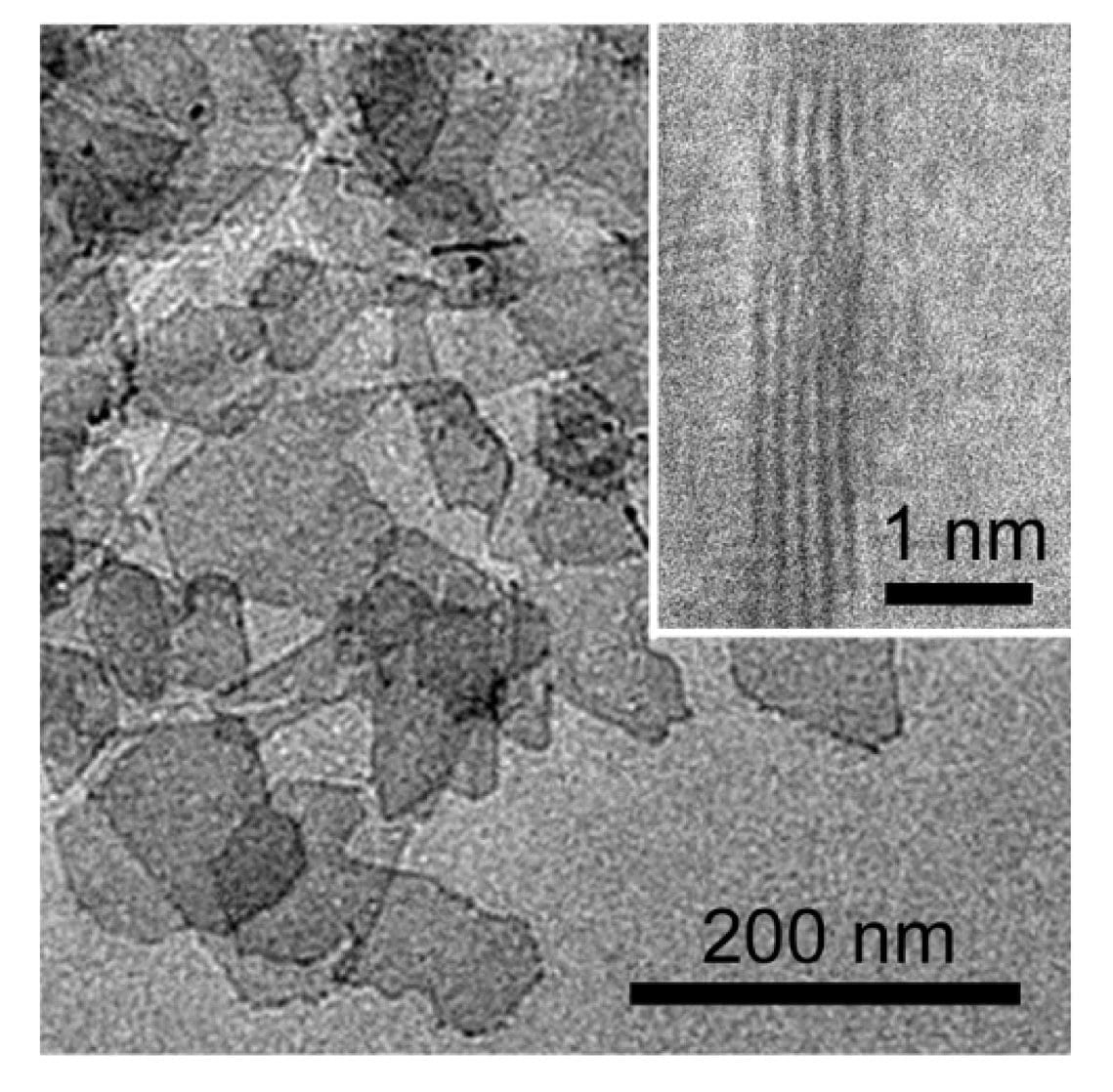

Cofacial cobalt porphyrins consist of two flat molecules called cobalt porphyrins, which are stacked on top of each other like sandwich bread and linked by ruthenium “clips.”

To create the final compounds, Cook’s lab designed porphyrins and clips with chemical properties that ensured they would connect to each other at the right spots. The team then mixed a solution of the porphyrins with the clips and added heat. In two days, the pieces had self-assembled to form the cofacial cobalt porphyrins.

A catalyst inspired by nature

Like the platinum catalyst they’re designed to replace, the cofacial cobalt porphyrins facilitate a chemical reaction in hydrogen fuel cells called oxygen reduction. This involves splitting an oxygen molecule into two separate oxygen atoms that can then bind with hydrogen to form water — an interaction that produces energy.

Scientists have long known that porphyrins are great at grabbing and splitting oxygen: In the human body, iron-based versions of these molecules are responsible for helping to convert the oxygen we breathe into water, releasing energy in the process, Cook says.

But designing artificial porphyrin structures that act as catalysts has been difficult, he adds. The process of creating these compounds is usually expensive, involving many steps and generating very little material at the end.

Self-assembly solves these problems: Cook’s team created 79 grams of cofacial cobalt porphyrins for every 100 grams of starter material — much better than the less than 1 percent yield that other labs have reported when synthesizing similar materials. In addition, his team was able to easily swap out and test ruthenium clips of different lengths to fine tune the compound’s electrochemical qualities with an eye toward designing an ideal catalyst.

“It is truly rewarding to work on the fundamental chemistry of this project, which could have a large impact on carbon-neutral energy conversion,” says Oldacre, the first author. “Using self-assembly techniques, we are able to make cheaper materials in 48 hours, without the difficult, time-consuming purification steps that other methods for synthesizing new compounds require.”

Learn more: Lego-like chemical building blocks assemble themselves to create a catalyst for hydrogen fuel cells

The Latest on: Hydrogen fuel cells

[google_news title=”” keyword=”hydrogen fuel cells” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Hydrogen fuel cells

- Varanasi pilot location for deployment of green hydrogen fuel cell inland vessels on NW-Ion April 27, 2024 at 3:13 pm

New Delhi, Varanasi has been selected as the pilot location for deployment of green hydrogen fuel cell inland vessels on National Waterways-I, aligning with the government's Harit Nauka guidelines, an ...

- World’s first hydrogen station for commercial trucks opens – is it too late?on April 27, 2024 at 7:58 am

FirstElement Fuels has opened the world's first large-scale hydrogen fueling station for heavy-duty commercial trucks at Port of Oakland.

- Really Cold Hydrogen Could Bring Driving Range Parity with Dieselon April 26, 2024 at 3:33 pm

The time it takes to fuel a hydrogen-powered fuel cell truck is already on par with diesel. But there is still a yawning gap when it comes to comparable driving range.

- RICE develops new underwater robot with a buoyancy control system using fuel cellson April 26, 2024 at 4:31 am

Rice University students have made a breakthrough in underwater robotics by creating a remotely operated vehicle (ROV) that utilizes water-splitting fuel cells for buoyancy control. This innovative ...

- Plug Power within months of getting third green hydrogen factory runningon April 25, 2024 at 3:21 pm

COLONIE – Fuel cell maker Plug Power says it has completed the ramp up of its two first green hydrogen plants in Tennessee and Georgia, with its third plant expected to be completed in the third ...

- GILLIG to develop hydrogen fuel cell powered buson April 25, 2024 at 9:05 am

GILLIG is collaborating with BAE Systems and Ballard Power Systems on the development of the hydrogen fuel cell bus.

- This legendary brand cracks the code: here’s the most powerful hydrogen fuel cellon April 25, 2024 at 7:29 am

Legendary brand has created the first lightweight hydrogen fuel cell: the most powerful, but the smallest ever seen in history ...

- White Paper: Battery electric vs. hydrogen fuel cell vs. HVO – which is the winning technology?on April 25, 2024 at 7:11 am

In this white paper, Einride compares the three most talked-about alternatives to diesel – battery electric, HVO biofuel, and hydrogen fuel cell – based on four essential factors for long-term ...

- The first big-rig hydrogen fuel station in the U.S. opens in Californiaon April 24, 2024 at 3:00 am

The Port of Oakland is home to the United States' first commercial hydrogen fuel station for big-rig trucks. It's a step on the road to cleaner trucking.

via Bing News