The lightweight skeletons of organisms such as sea sponges display a strength that far exceeds that of manmade products constructed from similar materials.

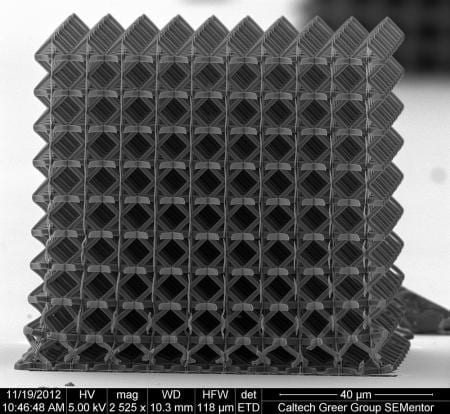

Scientists have long suspected that the difference has to do with the hierarchical architecture of the biological materials—the way the silica-based skeletons are built up from different structural elements, some of which are measured on the scale of billionths of meters, or nanometers. Now engineers at the California Institute of Technology (Caltech) have mimicked such a structure by creating nanostructured, hollow ceramic scaffolds, and have found that the small building blocks, or unit cells, do indeed display remarkable strength and resistance to failure despite being more than 85 percent air.

“Inspired, in part, by hard biological materials and by earlier work by Toby Schaedler and a team from HRL Laboratories, Caltech, and UC Irvine on the fabrication of extremely lightweight microtrusses, we designed architectures with building blocks that are less than five microns long, meaning that they are not resolvable by the human eye,” says Julia R. Greer, professor of materials science and mechanics at Caltech. “Constructing these architectures out of materials with nanometer dimensions has enabled us to decouple the materials’ strength from their density and to fabricate so-called structural metamaterials which are very stiff yet extremely lightweight.”

At the nanometer scale, solids have been shown to exhibit mechanical properties that differ substantially from those displayed by the same materials at larger scales. For example, Greer’s group has shown previously that at the nanoscale, some metals are about 50 times stronger than usual, and some amorphous materials become ductile rather than brittle. “We are capitalizing on these size effects and using them to make real, three-dimensional structures,” Greer says.

In an advance online publication of the journal Nature Materials, Greer and her students describe how the new structures were made and responded to applied forces.

The largest structure the team has fabricated thus far using the new method is a one-millimeter cube. Compression tests on the the entire structure indicate that not only the individual unit cells but also the complete architecture can be endowed with unusually high strength, depending on the material, which suggests that the general fabrication technique the researchers developed could be used to produce lightweight, mechanically robust small-scale components such as batteries, interfaces, catalysts, and implantable biomedical devices.

Greer says the work could fundamentally shift the way people think about the creation of materials. “With this approach, we can really start thinking about designing materials backward,” she says. “I can start with a property and say that I want something that has this strength or this thermal conductivity, for example. Then I can design the optimal architecture with the optimal material at the relevant size and end up with the material I wanted.”

The team first digitally designed a lattice structure featuring repeating octahedral unit cells—a design that mimics the type of periodic lattice structure seen in diatoms. Next, the researchers used a technique called two-photon lithography to turn that design into a three-dimensional polymer lattice. Then they uniformly coated that polymer lattice with thin layers of the ceramic material titanium nitride (TiN) and removed the polymer core, leaving a ceramic nanolattice. The lattice is constructed of hollow struts with walls no thicker than 75 nanometers.

“We are now able to design exactly the structure that we want to replicate and then process it in such a way that it’s made out of almost any material class we’d like—for example, metals, ceramics, or semiconductors—at the right dimensions,” Greer says.

The Latest Bing News on:

Structural metamaterials

- Structural Geologyon April 14, 2024 at 11:19 pm

55, Issue. 9, p. 1073. Lavishly illustrated in color, this textbook takes an applied approach to introduce undergraduate students to the basic principles of structural geology. The book provides ...

- What Is The Cost To Hire A Structural Engineer In 2024?on April 13, 2024 at 5:54 pm

A structural engineer inspection costs an average of $900, but the price can range anywhere from $300 to $2,000 depending on the extent of the related reports and drawings. When we include the ...

- Breakthrough 3D Printed Titanium Metamaterial Unlocks 'Supernatural' Strength for Aerospace and Medicineon April 10, 2024 at 6:49 pm

The world of materials science has reached a turning point with the advent of a 3D printed titanium metamaterial displaying levels of strength unattainable in natural or traditional manufactured ...

- Researchers Improve Energy Harvesting Efficiency with New Metasurfaceon April 3, 2024 at 5:59 am

Metamaterials are artificial structures that ... This technology, along with its applications in structural health monitoring, wireless sensing, and the Internet of Things, holds great potential ...

- MSc Structural Engineering / Overviewon October 24, 2023 at 5:05 am

As there is high demand for this course we operate a staged admissions process with selection deadlines throughout the year. Please find more information in our Application and Selection section. All ...

- Ceramic Textiles for Structural Elementson September 15, 2023 at 3:41 pm

The Ceramic Textile System from Flexbrick can be used as a structural system. In a similar way as in architectural concrete panels, Flexbrick ceramic tissues are easily combined for behaving as a ...

- Structural Biologyon August 19, 2023 at 9:25 am

This page provides educational resources, events, news and products related to structural biology. Content will cover aspects from advances in the analytical techniques used to the insights and wider ...

- Understanding Structural Biology, Its Applications and Creating a Molecular Modelon February 14, 2023 at 4:00 pm

The origins of modern structural biology date back to the 1910s, when the German physicist Max von Laue discovered that biological crystal samples irradiated with X-rays produced diffraction patterns ...

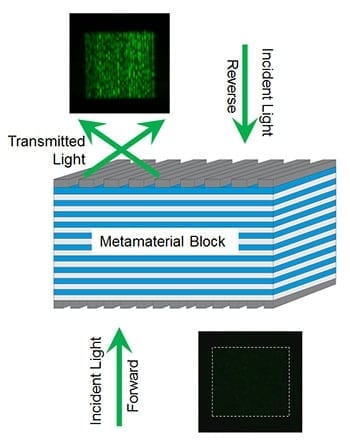

- Metamaterials and Metasurfaces: Engineered Structures Revolutionizing Light and Matter Interactionson August 18, 2020 at 1:09 pm

Steve Cummer, professor of electrical and computer engineering at Duke University, explains the concept of metamaterials using some simple illustrations. The essence of metamaterial design lies in ...

- Akim Akyurtluon August 3, 2019 at 2:03 pm

(Principal), Barry, C. (Principal) Nanostructured Sensing Elements for Structural Health Surveillance (2010), Grant - Army Research Laboratory Akyurtlu, A. (Co-Principal) Three Dimensional Isotropic ...

The Latest Google Headlines on:

Structural metamaterials

[google_news title=”” keyword=”Structural metamaterials” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Fix the internet

- It’s Time to Pass the Bill Mandating Refunds Each Time There’s an Internet Outageon May 12, 2024 at 9:22 pm

If you were paying a fixed amount monthly for your internet, and you had inconsistent or even zero service for days or even weeks at a time, shouldn’t your provider refund you the corresponding amount ...

- N.W.T. phone, internet outage improves as technicians fix wildfire-damaged lineon May 12, 2024 at 5:41 am

Technicians have been able to fix a fibre line north of a B.C. community impacted by wildfire to help begin restoring telecommunication services in the North, according to Northwestel. The company ...

- Why there's no internet across Tampa Bayon May 11, 2024 at 10:25 am

TAMPA, Kan. — An electrical fire on a utility pole caused internet outages on Saturday in Pinellas County.

- How to fix: Router doesn't connect to the internet after a reseton May 11, 2024 at 7:00 am

First things first, did you actually reset the router or simply restart it? If you didn’t hold the reset button long enough, the router may have just restarted instead of resetting. If you still see ...

- Phone and internet outage improves after technicians fix wildfire-damaged lineon May 10, 2024 at 10:43 pm

As of Saturday morning, all cellphone and internet service was down across Yukon. In N.W.T., residents of many communities including Fort Liard and Jean Marie River were reporting that Internet, ...

- Teams is showing the wrong time zone [Fix]on May 10, 2024 at 6:01 am

If Teams is showing the wrong time zone, check the language and time settings in Outlook is set correctly. Also, set the correct time zone on your PC.

- T-Mobile delays free internet loophole fix after running into a problemon May 9, 2024 at 1:40 pm

T-Mobile has reportedly delayed the roll out of address verification on gateways, as well as the launch of the new Away plan.

- 5 Ways to Fix the GTA V “Rockstar Game Services are Unavailable” Error on Windows PCson May 7, 2024 at 5:53 am

Here, we look at how you can fix Grand Theft Auto V’s “Rockstar game services are unavailable” error on Windows 11/10 PCs. Are you another player who can’t play GTA V or GTA Online because of that ...

- Give small businesses the ‘right to repair’on May 2, 2024 at 7:00 am

Thankfully, bipartisan members of Congress have introduced a commonsense proposal that would benefit small businesses and consumers: the Right to Equitable and Professional Auto Industry Repair Act.

- 5 Ways to Fix the Failed-to-Connect-to-Server Minecraft Error on Windows PCson April 30, 2024 at 9:25 am

This troubleshooting guide provides some possible resolutions for fixing the Minecraft error message that says, “Failed to connect to the server.” Are you seeking a fix for that server connectivity ...

The Latest Google Headlines on:

Fix the internet

[google_news title=”” keyword=”fix the internet” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]