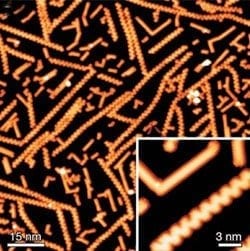

Eventually, graphene inks could lead to “applications in printable electronics like RFID tags, conductive transparent coatings, anything from sensors to flexible display applications

A digital screen that you can fold up like paper, solar cells embedded in house paint and a battery printed on the bottom of your phone — all this may soon be possible thanks to the so-called graphene ink, printed circuits made from graphene — a one-atom-thick layer of carbon that is the strongest, thinnest and most conductive material discovered yet.

Conductive inks — printed circuits — are already widely used to make touch screens, RFID tags (radio-activated ID chips) and small antennas in mobile phones. However, today’s conductive inks are usually metal-based, using materials like silver or copper powder.

These inks are expensive, can be toxic and require high temperatures to print. Graphene has long been seen as a cheaper and easier-to-use alternative, and many research teams — from Northwestern University in the U.S. to Northwestern University in the U.K. — have tried to make it work.

Among the few that seem to be succeeding is Haydale, a spin-off from Swansea University in Wales. The company currently mass-produces about one ton of graphene for commercial purposes a year — enough to make more than ten tons of conductive ink, the firm’s commercial director Ray Gibbs tells us. To make the ink, Haydale has recently partnered with Gwent Electronic Materials, a firm that supplies conductive inks for sensors and electronic instruments.

To produce the ink, Haydale uses very fine powered graphite – material widely used as lead in pencils – and puts it in a modified plasma reactor — a reactor where the plasma cloud is generated. Plasma is gas with charged particles, and the company uses it to turn the graphite into graphene. [See also Researchers Shrink Particle Accelerator to Table-top Size]

The process first purifies the graphite and then creates the one atom thick sheets of graphene. The material is then used to make the conductive ink.

Graphene-based inks are easier to handle than traditional metal-based ones, said Gibbs – less toxic, cheaper and easier to dry. If metal-based inks are not dried properly, they can swell, “which pushes the metal particles apart and reduces conductivity. Moreover, it can lead to failure when the ink is subject to bending, creasing or scratching.” Drying metal-based inks requires temperatures of 212 degrees Fahrenheit (100 degrees Celsius) or more; for graphene, about 140F (60 C) is enough.

The Latest Bing News on:

Graphene Ink

- Global Carbon Nanomaterials Markets Report 2024-2033 with Profiles of 590+ Leading Producers/Supplierson May 9, 2024 at 3:20 am

The "The Global Market for Carbon Nanomaterials 2024-2033" report has been added to ResearchAndMarkets.com's offering. The Global Market for Carbon Nanomaterials 2024-2033 provides a comprehensive ...

- Wonder Material 'More Remarkable' Than Graphene Has Medical Potentialon May 7, 2024 at 8:55 am

Scientists may have found a material "more remarkable" than graphene that presents a wealth of medical potential. Borophene is thinner, more conductive, lighter and stronger than graphene.

- The Flash Pro Plus gives you a power supply anywhere for only $199.97on April 27, 2024 at 7:00 am

TL;DR: Need to charge on the go? The Flash Pro Plus, a graphene power bank powered by Panasonic™, makes it easy to charge your Apple and Android devices anywhere. It’s now only $199.97 ...

- Conductive Ink Market Is Encouraged to Reach USD 5.6 Billion by 2033 at a CAGR of 6.3%on April 26, 2024 at 2:15 am

According to Market.us, the Conductive Ink Market size is projected to surpass around USD 5.6 billion by 2033, from USD 3.5 billion in 2023, and it is poised to reach a registered CAGR of 6.3% from ...

- Goldene: New 2D form of gold makes graphene look boringon April 17, 2024 at 12:29 am

Graphene is a bit like the Novak Djokovic of materials – it’s so damn talented that each new achievement feels passé. But now, an exciting new upstart is challenging graphene’s title.

- Scientists finally make ‘goldene’, potentially breakthrough new materialon April 16, 2024 at 3:26 am

The work follows the successful production of graphene, which is made out of a single layer graphite atoms. That has been hailed as a miracle material: it is astonishingly strong, and much better ...

- Advancing biomedical diagnostics: Graphene sensor inks pave the way for precision biosensingon April 10, 2024 at 5:00 pm

The use of graphene as a sensory ink improves electrical conductivity, sensitivity, and reaction rate in a biomedical sensor, allowing for faster and more accurate findings than existing approaches.

- Graphene - where is our promised wonder material?on February 29, 2024 at 3:44 pm

Graphene is considered one of the most important breakthroughs in material science since its discovery. This “wonder material” was widely overhyped, and still hasn’t lived up to its potential.

- 3D Grapheneon August 13, 2020 at 6:15 pm

For instance, they show the ability of 3D-printed graphene ink scaffolds to induce neurogenic differentiation of adult mesenchymal stem cells without the need for any other neurogenic growth factors ...

- Graphene Batteries Explainedon August 13, 2020 at 12:47 pm

American Chemical Society) Even 3D-printed graphene batteries, using graphene ink, have already been demonstrated. Another exciting development is the fact that graphene allows the fabrication of ...

The Latest Google Headlines on:

Graphene Ink

[google_news title=”” keyword=”Graphene Ink” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Graphene-based inks

- Wonder Material 'More Remarkable' Than Graphene Has Medical Potentialon May 8, 2024 at 4:20 am

Borophene is already thinner and more conductive than graphene, and scientists have altered it to make it even more special.

- First Graphene Ltd FGPHFon May 5, 2024 at 5:00 pm

Morningstar Quantitative Ratings for Stocks are generated using an algorithm that compares companies that are not under analyst coverage to peer companies that do receive analyst-driven ratings ...

- Pacific Basin to apply graphene-based propeller coatings on 40 shipson April 26, 2024 at 10:44 am

Following successful application and obtaining positive results from the graphene-based propeller coating on one of its Supramax dry bulk vessels, Pacific Basin has started the rollout of XGIT-PROP ...

- Conductive Ink Market Is Encouraged to Reach USD 5.6 Billion by 2033 at a CAGR of 6.3%on April 26, 2024 at 2:15 am

According to Market.us, the Conductive Ink Market size is projected to surpass around USD 5.6 billion by 2033, from USD 3.5 billion in 2023, and it is poised to reach a registered CAGR of 6.3% from ...

- Samsung's New Graphene Batteryon April 19, 2024 at 4:59 pm

v=YOrJJKW31OAProducer: Dagogo Altraide» Twitter | @ColdFusion_TV Travis Kelce inks record-setting contract ... live in isn't California or New York, based on data. Here are the top 10.

- Overcoming the Graphene Challenge: Haydale's Novel Plasma Functionalisation Process Paves the Way for Seamless Graphene Integrationon April 11, 2024 at 7:39 am

The process supports a fine control of the chemical structure of Graphene, allowing it to quickly disperse into a variety of media, including water, inks ... and solvent-based pastes or as ...

- Advancing biomedical diagnostics: Graphene sensor inks pave the way for precision biosensingon April 10, 2024 at 5:00 pm

These inks have the ability to revolutionize ... and manufacture of plasma-functionalised graphene-enhanced products, all primarily based in the UK. Manufacture and sale of Silicon Carbide cutting ...

- Graphene-enhanced biosensor inks: Revolutionizing healthcare technologyon March 13, 2024 at 2:17 am

The inks improve electrical conductivity and enzyme immobilization by adding extra chemistries and cutting-edge materials like graphene. The manufacture and disposal of medical equipment have a ...

- Graphene - where is our promised wonder material?on February 29, 2024 at 3:44 pm

Although it has all of the characteristics to be an excellent material in theory, manufacturing defect-free graphene is often too expensive. Its price can vary a lot based on the manufacturing ...

- Global Graphene Companies – Manufacturers and Supplierson August 14, 2020 at 11:38 pm

Graphene is the name for a honeycomb sheet of carbon atoms. It is the strongest known material, yet it is also stretchy. It can conduct electricity 100x better than silicon and heat 10x better than ...

The Latest Google Headlines on:

Graphene-based inks

[google_news title=”” keyword=”Graphene-based inks” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]