Washington State University researchers have developed a unique, 3-D manufacturing method that for the first time rapidly creates and precisely controls a material’s architecture from the nanoscale to centimeters – with results that closely mimic the intricate architecture of natural materials like wood and bone.

They report on their work in the journal Science Advances (http://advances.sciencemag.org/content/3/3/e1601986) and have filed for a patent.

The work has many high-tech engineering applications.

The work has many high-tech engineering applications.

“This is a groundbreaking advance in the 3-D architecturing of materials at nano- to macroscales with applications in batteries, lightweight ultrastrong materials, catalytic converters, supercapacitors and biological scaffolds,” said Rahul Panat, associate professor in the School of Mechanical and Materials Engineering, who led the research. “This technique can fill a lot of critical gaps for the realization of these technologies.”

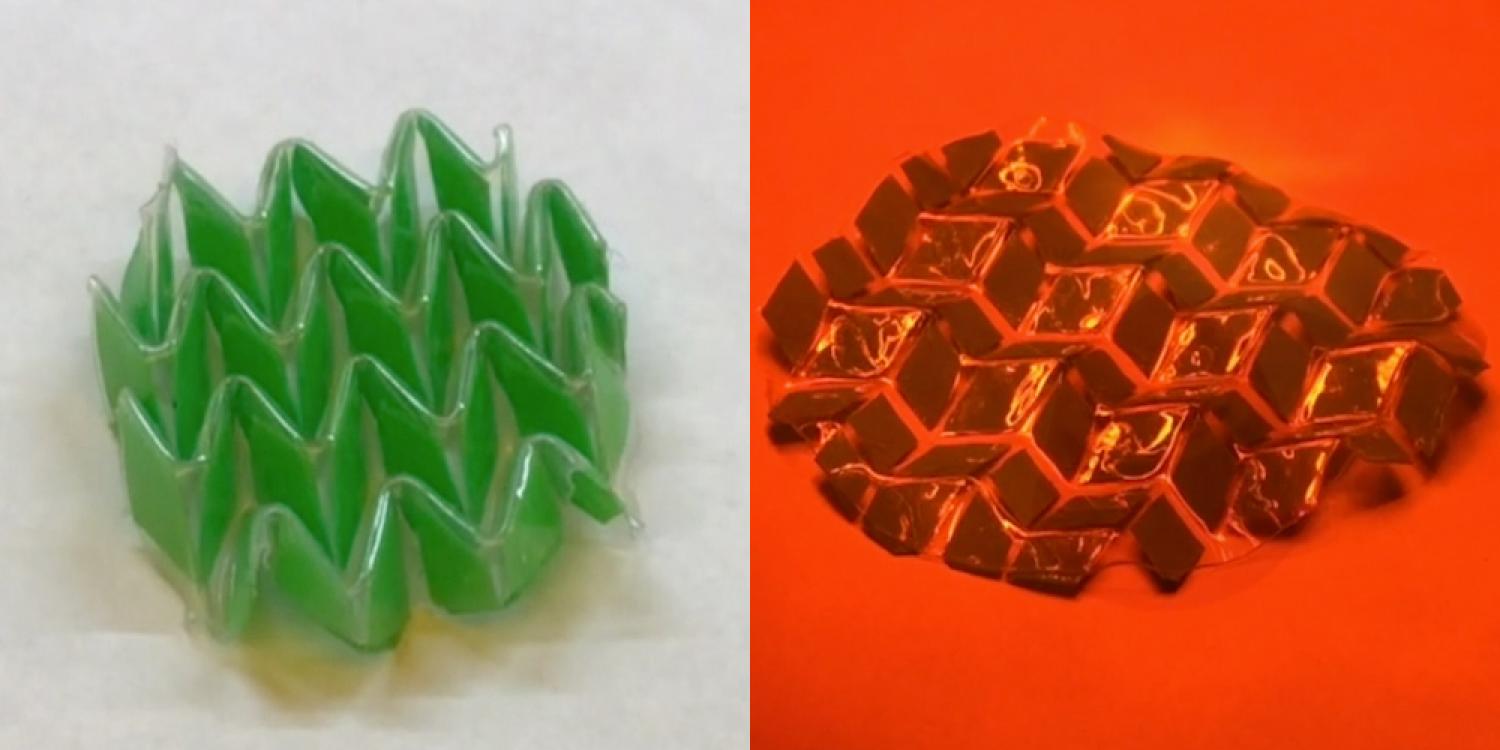

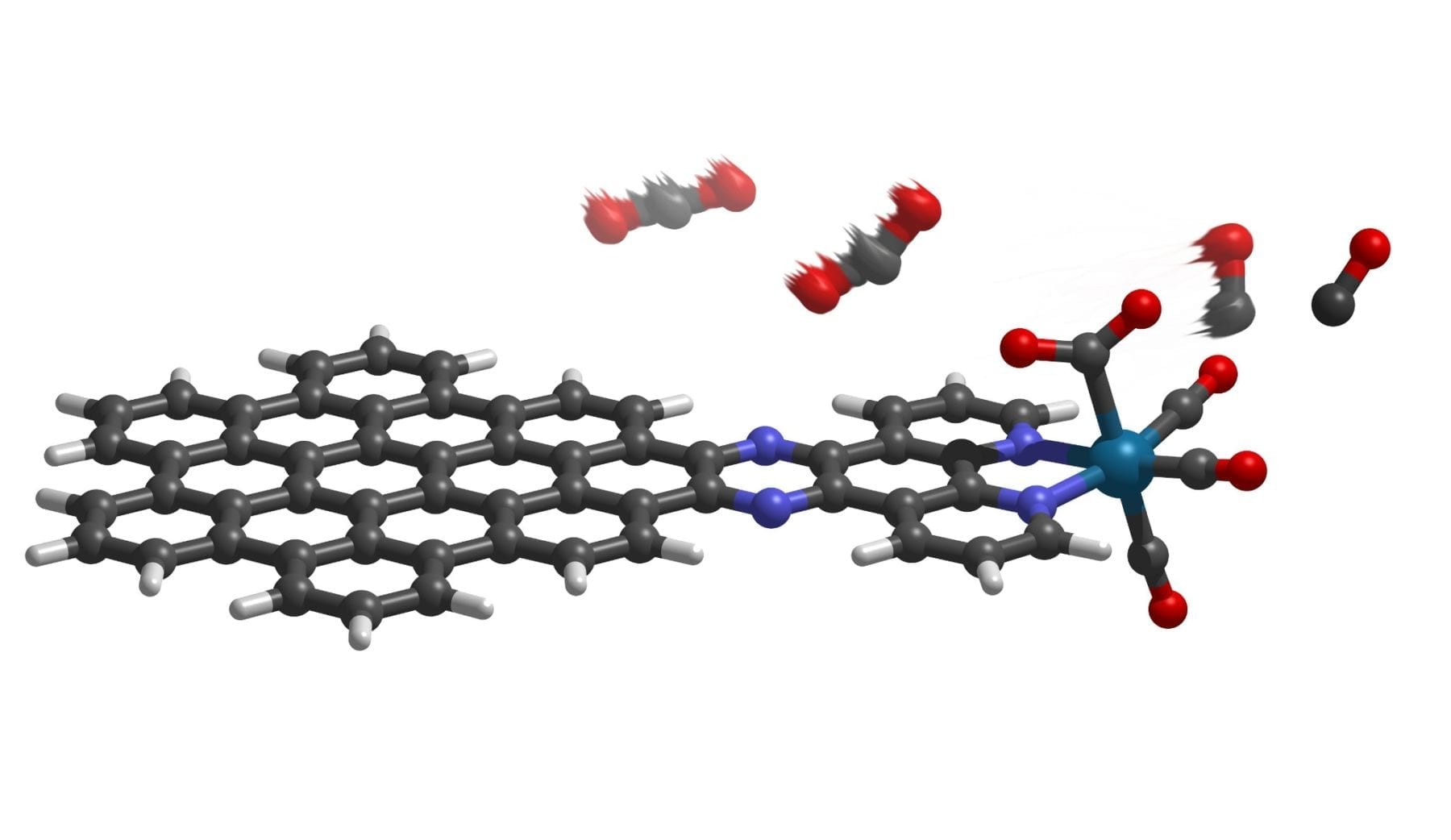

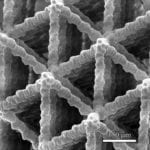

The WSU research team used a 3-D printing method to create foglike microdroplets that contain nanoparticles of silver and to deposit them at specific locations. As the liquid in the fog evaporated, the nanoparticles remained, creating delicate structures. The tiny structures, which look similar to Tinkertoy constructions, are porous, have an extremely large surface area and are very strong.

Silver was used because it is easy to work with. However, Panat said, the method can be extended to any other material that can be crushed into nanoparticles – and almost all materials can be.

The researchers created several intricate and beautiful structures, including microscaffolds that contain solid truss members like a bridge, spirals, electronic connections that resemble accordion bellows or doughnut-shaped pillars.

The manufacturing method itself is similar to a rare, natural process in which tiny fog droplets that contain sulfur evaporate over the hot western Africa deserts and give rise to crystalline flower-like structures called “desert roses.”

Because it uses 3-D printing technology, the new method is highly efficient, creates minimal waste and allows for fast and large-scale manufacturing.

The researchers would like to use such nanoscale and porous metal structures for a number of industrial applications; for instance, the team is developing finely detailed, porous anodes and cathodes for batteries rather than the solid structures that are now used. This advance could transform the industry by significantly increasing battery speed and capacity and allowing the use of new and higher energy materials.

Learn more: Novel 3-D manufacturing builds complex, bio-like materials

[osd_subscribe categories=’3D-manufacturing’ placeholder=’Email Address’ button_text=’Subscribe Now for any new posts on the topic “3D MANUFACTURING”‘]

Receive an email update when we add a new 3D MANUFACTURING article.

The Latest on: 3D manufacturing

[google_news title=”” keyword=”3D manufacturing” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: 3D manufacturing

- US signs Aerojet to 3D-print hypersonic propulsion system prototypeon May 9, 2024 at 1:44 am

Aerojet Rocketdyne has been given a contract by the US Department of Defense (DoD) to develop a hypersonic propulsion prototype through additive manufacturing. The $22 million contract from the DoD ...

- MTC installs Lithoz CeraFab S65 machine to drive industrial ceramic 3D printing in the UKon May 9, 2024 at 1:24 am

The Manufacturing Technology Centre (MTC), the UK’s national centre for additive manufacturing, has installed a Lithoz CeraFab S65 3D printer.

- Camhirst Robots Introduces Innovative 3D Construction Printing Technology in Greater Manchester to Address Global Housing Shortageon May 8, 2024 at 12:34 am

Ashton Under Lyne, Greater Manchester--(Newsfile Corp. - May 8, 2024) - Camhirst Robots, a pioneering robotics company, has announced the opening of its new headquarters in Ashton Under Lyne and its ...

- MIT spin-off Rapid Liquid Print raises $7M for 3D printingon May 7, 2024 at 1:30 pm

MIT spin-off Rapid Liquid Print has raised $7 million in funding for its novel liquid-based 3D printing technology.

- Farsoon introduces large-format 12-laser metal 3D printer at TCT Asiaon May 7, 2024 at 9:46 am

The developer of polymer laser sintering and metal laser melting systems says the FS811M features one of the biggest build volumes on the metal laser powder bed fusion market at 840 × 840 x 960mm.

- Pelagus 3D achieves key ISO certificationson May 7, 2024 at 5:07 am

Pelagus 3D, headquartered in Singapore, reports it has achieved International Standard requirements ISO 9001:2015, ISO 14001:2015, and ISO 45001: 2018 certifications across its global operations. This ...

- Endeavor 3D integrates Materialise CO-AM with its fleet of HP Additive Manufacturing machineson May 7, 2024 at 5:01 am

Endeavor 3D has announced it is integrating the Materialise CO-AM platform to bolster its HP Additive Manufacturing machine production capacity.

- This gigantic 3D printer could reinvent manufacturingon May 7, 2024 at 2:00 am

A massive additive manufacturing device that can build houses, and a whole lot more has just been unveiled at the University of Maine.

- Additive manufacturing could turn the tides for marine energy technologieson May 6, 2024 at 11:28 am

Milk and cookies. Peanut butter and jelly. Macaroni and cheese. All delightfully perfect pairs. Researchers at the National Renewable Energy Laboratory (NREL) discovered another promising pair: marine ...

via Bing News