Manufacturers may soon have a speedy and nondestructive way to test a wide array of materials under real-world conditions, thanks to an advance that researchers at the National Institute of Standards and Technology (NIST) have made in roll-to-roll measurements.

Roll-to-roll measurements are typically optical measurements for roll-to-roll manufacturing, any method that uses conveyor belts for continuous processing of items, from tires to nanotechnology components.

In order for new materials such as carbon nanotubes and graphene to play an increasingly important role in electronic devices, high-tech composites and other applications, manufacturers will need quality-control tests to ensure that products have desired characteristics, and lack flaws. Current test procedures often require cutting, scratching or otherwise touching a product, which slows the manufacturing process and can damage or even destroy the sample being tested.

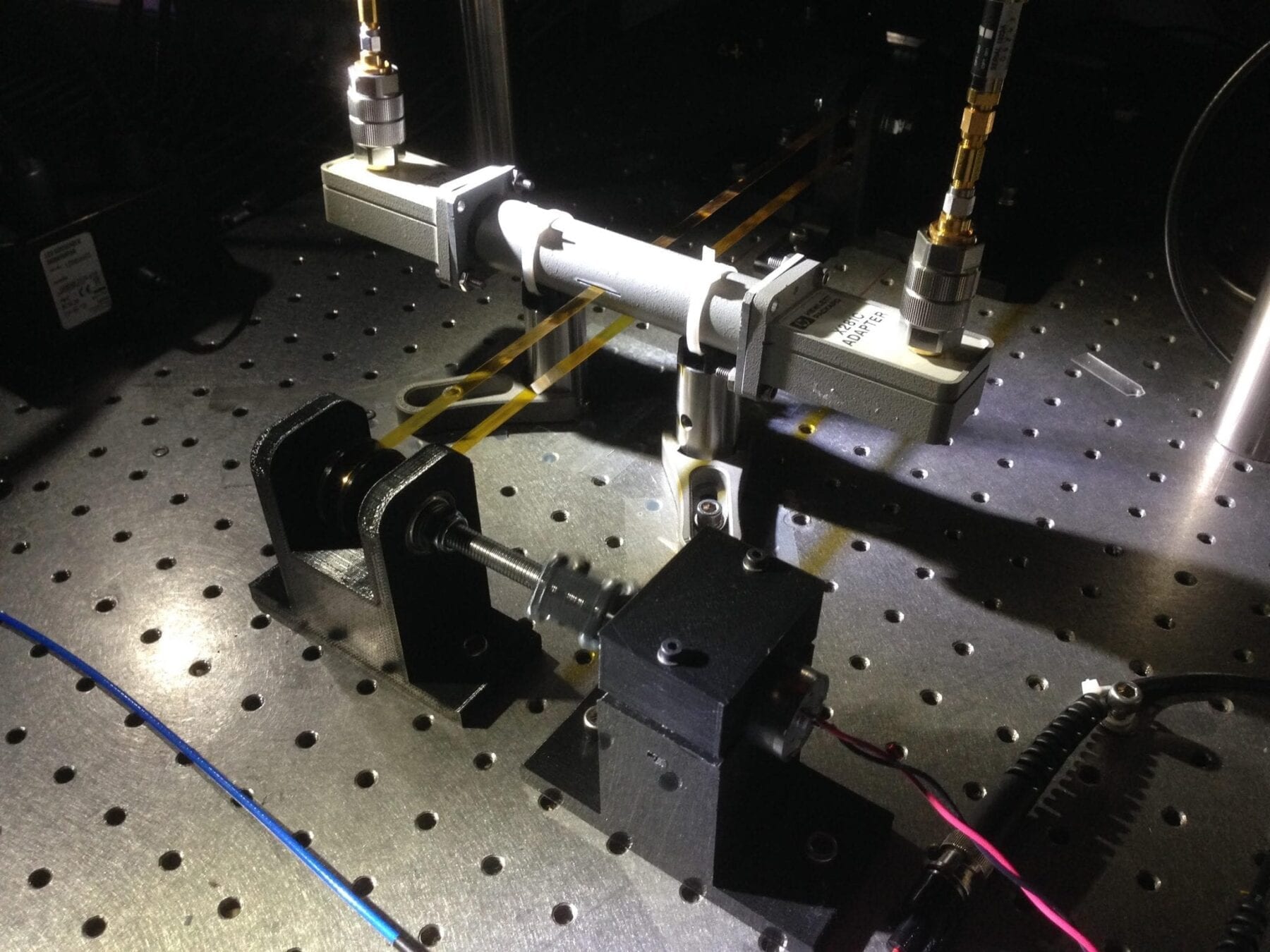

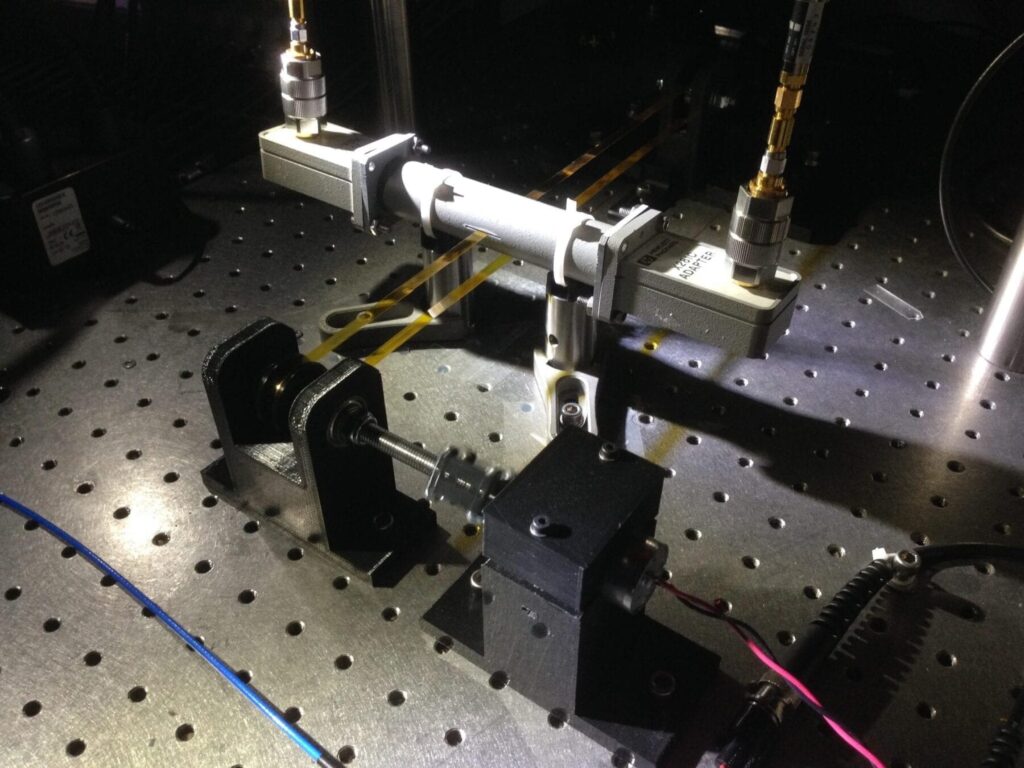

To add to existing testing non-contact methods, NIST physicists Nathan Orloff, Christian Long and Jan Obrzut measured properties of films by passing them through a specially designed metal box known as a microwave cavity. Electromagnetic waves build up inside the cavity at a specific “resonance” frequency determined by the box’s size and shape, similar to how a guitar string vibrates at a specific pitch depending on its length and tension. When an object is placed inside the cavity, the resonance frequency changes in a way that depends on the object’s size, electrical resistance and dielectric constant, a measure of an object’s ability to store energy in an electric field. The frequency change is reminiscent of how shortening or tightening a guitar string makes it resonate at a higher pitch, says Orloff.

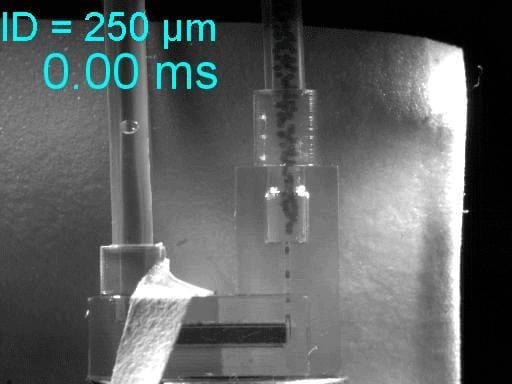

The researchers also built an electrical circuit to measure these changes. They first tested their device by running a strip of plastic tape known as polyimide through the cavity, using a roll-to-roll setup resembling high-volume roll-to-roll manufacturing devices used to mass-produce nanomaterials. (See video.) As the tape’s thickness increased and decreased—the researchers made the changes in tape thickness spell “NIST” in Morse code—the cavity’s resonant frequency changed in tandem. So did another parameter called the “quality factor,” which is the ratio of the energy stored in the cavity to the energy lost per frequency cycle. Because polyimide’s electrical properties are well known, a manufacturer could use the cavity measurements to monitor whether tape is coming off the production line at a consistent thickness—and even feeding back information from the measurements to control the thickness.

Alternatively, a manufacturer could use the new method to monitor the electrical properties of a less well-characterized material of known dimensions. Orloff and Long demonstrated this by passing 12- and 15-centimeter-long films of carbon nanotubes deposited on sheets of plastic through the cavity and measuring the films’ electrical resistance. The entire process took “less than a second,” says Orloff. He added that with industry-standard equipment, the measurements could be taken at speeds beyond 10 meters per second, more than enough for many present-day manufacturing operations.

The new method has several advantages for a thin-film manufacturer, says Orloff. One, “You can measure the entire thing, not just a small sample,” he said. Such real-time measurements could be used to tune the manufacturing process without shutting it down, or to discard a faulty batch of product before it gets out the factory door. “This method could significantly boost prospects of not making a faulty batch in the first place,” Long noted.

And because the method is nondestructive, Orloff added, “If a batch passes the test, manufacturers can sell it.”

Films of carbon nanotubes and graphene are just starting to be manufactured in bulk for potential applications such as composite airplane materials, smartphone screens and wearable electronic devices.

Orloff, Long and Obrzut submitted a patent application for this technique in December 2015.

A producer of such materials has already expressed interest in the new method, said Orloff. “They’re really excited about it.” He added that the method is not specific to nanomanufacturing, and with a properly designed cavity, could also help with quality control of many other kinds of products, including tires, pharmaceuticals and even beer.

Learn more: NIST Invents Fleet and Fast Test for Nanomanufacturing Quality Control

The Latest on: Nanomanufacturing Quality Control

[google_news title=”” keyword=”Nanomanufacturing Quality Control” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Nanomanufacturing Quality Control

- PCAOB adopts new quality control standardon May 14, 2024 at 6:14 am

The Public Company Accounting Oversight Board (PCAOB) has adopted a new standard designed to lead registered public accounting firms to significantly improve their quality control (QC) systems. The ...

- PCAOB OKs auditor responsibility and quality control standardson May 13, 2024 at 12:59 pm

The Public Company Accounting Oversight Board approved two new standards, on systems of quality control and the general responsibilities of the auditor.

- Image quality and quality control in diagnostic nuclear medicineon May 8, 2024 at 7:03 am

A quality control (QC) programme is aimed at maintaining high performance of equipment regardless of its age. It starts with the initial acceptance test, which consists of a QC-programme to assess ...

- Best Pest Control Companies Of 2024on May 8, 2024 at 3:00 am

Hiring a professional pest control service to eliminate and control these stubborn creatures is typically the best way to deal with the situation. Whether your home is in the grips of an invasion ...

- Forged Aluminum Parts: Why Manufacturer, Materials, And Quality Control Matteron May 7, 2024 at 3:26 am

Forged aluminum parts play a critical role in numerous industries, from automotive and aerospace to consumer electroni ...

- Ten things you should know about nanotechnologyon January 13, 2024 at 10:30 am

Of course, the chemical industry has long been working with nanoscale particles and pigments, but this falls more into the realm of chemistry than nanomanufacturing ... basic problems such as being ...

- Quality Assurance & Controlon December 11, 2022 at 7:47 am

Quality assurance (QA) prevents and detects quality problems. Quality control (QC) detects errors in the product. QC evaluates the developed product itself. Another way to look at it would be to think ...

- Quality Assurance and Quality Control in Nuclear Facilities and Activitieson August 9, 2020 at 10:03 am

This publication explains the concepts of quality assurance and quality control. It provides examples, illustrated by good practices, of their implementation within the processes of the management ...

- Quality control and quality assuranceon July 25, 2020 at 9:11 pm

This will save the business time and money. Quality control ensures that no faulty product reaches the consumer as all finished products are checked thoroughly. This is where quality is built into ...

- Robustness of a Quality Control Methodon July 20, 2018 at 10:34 pm

Robustness The robustness of the quality control method measures how effectively it influences design to achieve independence from manufacturing variations. If product design requires a ...

via Bing News