A new method of producing solar cells could reduce the amount of silicon per unit area by 90 per cent compared to the current standard. With the high prices of pure silicon, this will help cut the cost of solar power.

“We’re using less expensive raw materials, and smaller amounts of them, we have fewer production steps and our total energy consumption is potentially lower,” explain PhD candidate Fredrik Martinsen and Professor Ursula Gibson, from NTNU’s Department of Physics.

They recently published their technique in Scientific Reports. Their processing technique allows them to make solar cells from silicon that is 1000 times less pure, and thus less expensive, than the current industry standard.

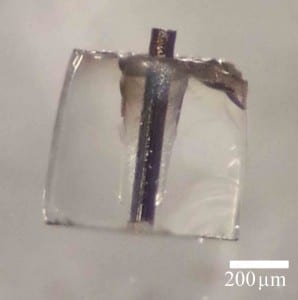

Glass fibres with a silicon core

The researchers’ solar cells are composed of silicon fibres coated in glass. A silicon core is inserted into a glass tube about 3 mm in diameter. This is then heated up, so that the silicon melts and the glass softens. The tube is stretched out into a thin glass fibre filled with silicon. The process of heating and stretching makes the fibre up to 100 times thinner.

This is the widely accepted industrial method used to produce fibre optic cables. But researchers at the Department of Physics at NTNU, working with collaborators at Clemson University in the USA, are the first to use silicon-core fibres made this way in solar cells. The active part of these solar cells is the silicon core, which has a diameter of about 100 micrometres.

Lower energy consumption

This production method also enabled them to solve another problem: traditional solar cells require pure silicon. The process of manufacturing a pure silicon wafers is laborious, energy-intensive and expensive.

“We can use relatively dirty silicon, and the purification occurs naturally as part of the process of melting and re-solidifying in fibre form. This means that you save energy, and several production steps.”

It is estimated that it will take roughly one-third of the energy to produce solar cells with this method compared to the traditional approach of producing silicon wafers.

The Latest on: Cheaper solar cells

[google_news title=”” keyword=”cheaper solar cells” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Cheaper solar cells

- Eskom or solar power – What is cheaper?on May 8, 2024 at 7:20 am

With frequent electricity tariff hikes, many South Africans are installing or considering installing solar panels. Apart from the convenience of sidestepping loadshedding, which one is actually ...

- Are solar panels worth it in Hawaii?on May 8, 2024 at 5:35 am

Hawaii has the highest average solar potential of any state, relatively low rooftop solar installation costs and generally solar-friendly policies. These and other factors make it the best state for ...

- Solar panel world record broken in huge boost for renewableson May 8, 2024 at 5:21 am

() Scientists have broken the world record for solar panel efficiency, less than six months after setting the previous record. A research team from Chinese firm LONGi Green Energy Technology, which is ...

- Cheap Chinese solar panels are a blessing for Europe, not a curseon May 7, 2024 at 10:00 am

Rajaratnam School of International Studies at Nanyang Technological University. The announcement by Switzerland's Meyer Burger earlier this year that it would close its solar photovoltaic module ...

- Swedish startup wins EU funding to print organic indoor solar panelson May 7, 2024 at 7:55 am

Epishine's organic solar panels harness indoor light to power electronics and Internet of Things (IoT) devices.

- Can’t install your own solar panels? Some areas let you join a community project.on May 6, 2024 at 2:55 am

For four generations, Steve Wine’s family has tended a 600-acre farm in Virginia’s Shenandoah Valley, raising steers and growing corn, soybeans and alfalfa. The farm has struggled in recent years with ...

- First Solar Stock Jumps As Prospect of Cheaper Borrowing Costs Drives Chart Breakouton May 5, 2024 at 7:33 pm

First solar shares will be in the spotlight again Monday after the company broke out from a key chart pattern on Friday after a soft April jobs report fueled hopes that sooner-than-expected interest ...

- Can perovskite solar cells outshine silicon and revolutionize solar energy?on May 3, 2024 at 3:06 am

Perovskite, a revolutionary material, promises to surpass silicon efficiency and usher in a new era of affordable, sustainable solar energy.

- House Bill 1032 fails to require proper placement of panels on rooftops | PennLive letterson April 30, 2024 at 2:52 am

That would be by placing the panels on rooftops, rather than on the ground. It is actually cheaper to install solar panels on rooftops than on the ground, but even if it wasn’t, rooftop placement ...

- The Rise In Solar Waste Is Only Half The Truthon April 29, 2024 at 3:30 am

The other half of the truth concerns solar panel waste management which brings us to the question: How will we manage this considerable waste?

via Bing News