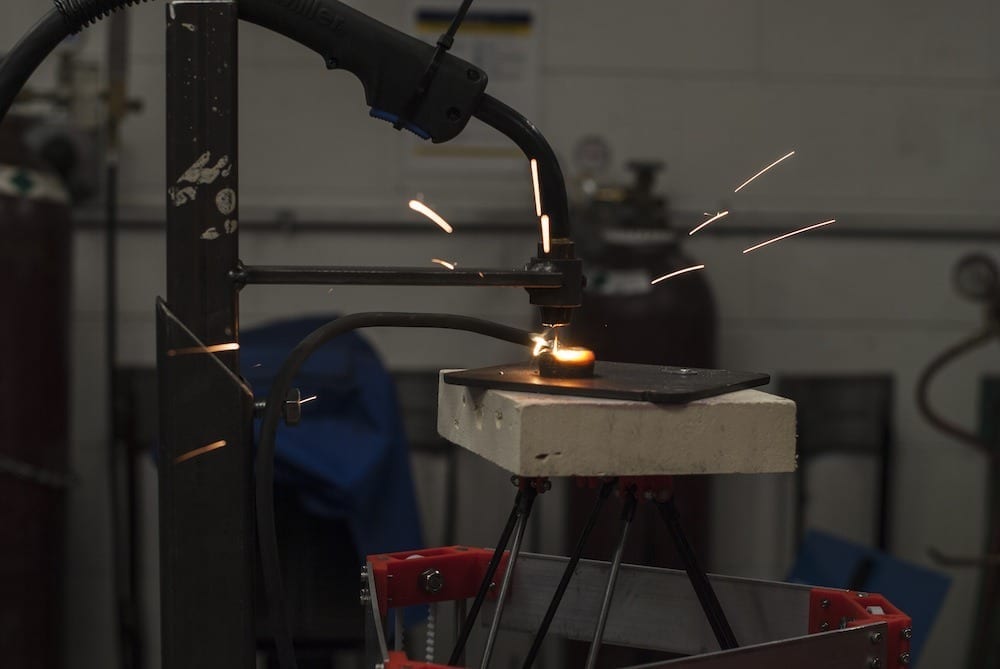

Anyone with access to a welder and the Internet soon could make his or her own replacement parts or tools with a new 3D metal printer that can be built in any garage.

Until recently, most of the 3D printing hype has swirled around plastic 3D printers, which have been used to make everything from clothing to art. And while 3D metal printers do exist, their price tag starts at a half million dollars.

Now, scientists have built an open-source 3D metal printer that costs under $1,200, sharing their design and software with the maker community.

“We have open-sourced the plans,” in the hopes of accelerating the technology by allowing others to build upon the design, said projectleader Joshua Pearce, a materials engineer at Michigan Technological University in Houghton. [The 10 Weirdest Things Created By 3D Printing]

The snazzy device is modeled after a RepRap (short for “replicating rapid prototype”), a 3D printer that can print most of its own components. The printer uses a metal inert gas (MIG) welder to lay down thin layers of steel, much like plastic printers do, and build complex geometric objects. All of the parts needed to build the metal printer are things one could buy or print using a plastic 3D printer, Pearce told LiveScience.

Pearce envisions the printer being used to make replacement parts for things such as bicycles or to print scientific tools, which could radically reduce the cost of lab equipment, he said.

“I hope to see a large number of small companies starting up to make specialty parts,” he said.

The Latest on: 3D Metal Printer

- 3D Printing Finds a Homeon May 2, 2024 at 8:49 am

“Prefabricated 3D printed homes reduce the amount of labor required to build a home, thereby making homes safer, potentially cheaper, and much faster from design to completion,” says Buff López, an ...

- US Navy Continues Onboard 3D Printing Initiative for Enhanced Self-Sufficiencyon May 2, 2024 at 7:00 am

The United States Navy has recently integrated a Xerox ElemX 3D printer aboard the USS San Diego to boost self sufficiency.

- 3D Printed Wearables Market to See Massive Growth by 2024-2032on May 1, 2024 at 2:45 pm

According to a new market research report published by Report Ocean, the global 3D Printed Wearables Market is anticipated to grow at a CAGR of $%, during the forecast period. The market is estimated ...

- 3D Printing to Maintain Cornell’s Eco-Friendly Lake Source Cooling Systemon May 1, 2024 at 7:00 am

Cornell University has turned to 3D printing to enhance its routine cleaning and maintenance of its Lake Source Cooling system.

- Shhh! 3 Secret 3D Printing Stocks Flying Below Wall Street’s Radaron May 1, 2024 at 3:30 am

InvestorPlace - Stock Market News, Stock Advice & Trading Tips One of the best investment strategies for long-term growth is twofold: pick an ...

- Mantle launches 420 Stainless Steel for P-200 metal 3D printing systemon May 1, 2024 at 1:50 am

The Mantle 420 Stainless Steel is said to be chemically equivalent to traditional 420 stainless steel, boasting high strength, hardness, corrosion resistance and polish ability.

- 3 3D Printing Stocks With the Potential to Make You an Overnight Millionaireon April 30, 2024 at 4:07 am

Not too long ago, analysts and early adopters touted the technology of 3D printing as the future of manufacturing. Then came market corrections and concerns surrounding the feasibility of long-term ...

- INDO-MIM taps 3D printing in precision manufacturingon April 25, 2024 at 6:27 pm

The precision metal parts manufacturer is using HP’s Metal Jet S100 printers to produce components using metal powder for the automotive, healthcare and other industries ...

- Rice University Students Develop Affordable Metal 3D Printer Prototype Using Cold-Spray Technologyon April 25, 2024 at 9:47 am

Students at Rice University have developed an incredibly inexpensive metal 3D printer prototype. Researchers at Virginia Tech have taken on a big challenge: making wind turbines sustainable.

- Students build low-cost cold spray metal 3D printer prototypeon April 24, 2024 at 1:33 pm

A team of Rice University students has developed a cold spray metal 3D printing device that relies on pressure and velocity rather than temperature to create a metal part. Their work could help expand ...

via Bing News

The Latest on: 3D printing

- British homes could soon be built by 3D printer, expert says in astonishing predictionon May 2, 2024 at 11:11 am

British families could be opting for 3D printed-properties, houseboats and multi-generational homes by 2040 - according to a new AI prediction of future British living. Over the next three decades, AI ...

- 3D Printing Finds a Homeon May 2, 2024 at 8:49 am

“Prefabricated 3D printed homes reduce the amount of labor required to build a home, thereby making homes safer, potentially cheaper, and much faster from design to completion,” says Buff López, an ...

- INTAMSYS Becomes 3D Printing Equipment Supplier for the WORLDSKILLS LYON 2024 COMPETITIONon May 2, 2024 at 7:54 am

INTAMSYS has officially signed a sponsorship contract with WorldSkills Lyon 2024, becoming the supplier of FFF 3D printing equipment for the Mechanical ...

- Study unveils 3D printing PQD-polymer architectures at room temperatureon May 2, 2024 at 7:52 am

A technology enabling the fabrication of intricate three-dimensional (3D) quantum dot (QD)-based structures at room temperature has been developed.

- A 3D Printer On Every Desk? Why Companies Are Buying More 3D Printerson May 2, 2024 at 4:56 am

Entry-level desktop 3D printers saw record sales in 2023. It’s not the number of machines sold that’s surprising; it’s who’s buying them: businesses.

- Grayslake man used 3D printer to make guns, gun parts, sheriff’s police sayon May 2, 2024 at 4:44 am

Once Best was under arrest, police searched his home and seized 64 machine gun conversion devices that appear to have been manufactured using a 3D printer, as well as pistol frames and rifle parts ...

- Teachers at Deer Valley create tool using 3D printer to help a student communicate betteron May 1, 2024 at 9:59 pm

Thanks to a 3D printer, the teachers created a tool for the student that ultimately helped her communicate better. At Deer Valley, their motto is “everyone deserves a voice” and that’s exactly what ...

- Marriage of synthetic biology and 3D printing produces programmable living materialson May 1, 2024 at 6:42 am

Scientists are harnessing cells to make new types of materials that can grow, repair themselves and even respond to their environment. These solid "engineered living materials" are made by embedding ...

- Shhh! 3 Secret 3D Printing Stocks Flying Below Wall Street’s Radaron May 1, 2024 at 3:30 am

InvestorPlace - Stock Market News, Stock Advice & Trading Tips One of the best investment strategies for long-term growth is twofold: pick an ...

- 3D Printing in Biomedical Sensing Technologyon April 30, 2024 at 5:00 pm

3D printing is used to create real-life 3D objects from a digital model, facilitating the realization of ideas and concepts with high accuracy. Various 3D printing technologies exist, including ...

via Bing News