Bioprinting: From concept to reality

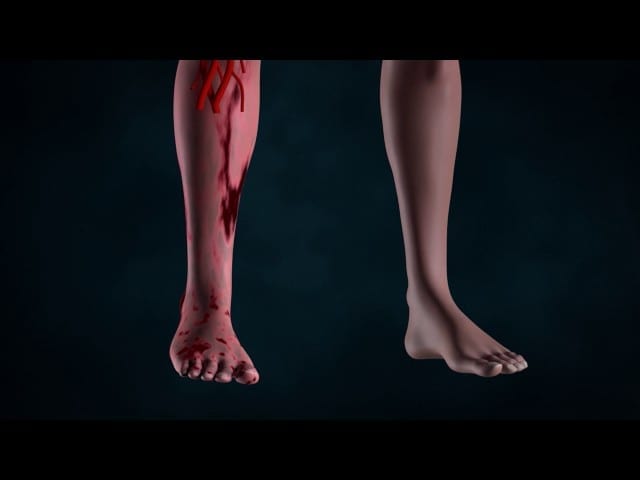

The human cell represents the smallest functional unit of life. All tissues in the body are composed of multiple cell types, typically arranged in a 3-D architecture that is relevant to the functions they carry out. Since cells were first isolated and grown in the laboratory environment, biologists and engineers have pursued the utilization of these tiny building blocks in the reconstruction and regeneration of functional tissue. Whether used in a controlled laboratory setting to model specific diseases and test the effects of drugs, or delivered into the body as therapeutics for the treatment of disease, the common goal is to establish or re-establish in vivo-like function.

The field of tissue engineering has deployed several fabrication strategies aimed at bringing cells and structure together to generate tissue. Biomaterial scaffolding—which provides structural support and can be formed into biologically relevant shapes—has been combined with cells to generate hybrid 3-D structures for use as tissue surrogates in vitro and in vivo. Protocols have been developed that enable removal of living cells from native tissues, leaving only a natural scaffolding of extracellular matrix, which can then be re-seeded with cells to reconstruct or partially reconstruct 3-D tissues. Another approach to soft tissue reconstruction has been the development of cell-laden hydrogels, which are often cast into a specific shape and placed into a permissive environment in vitro or in vivo that allows maturation and establishment of tissue-specific characteristics. In recent years, with the advancement of 3-D printing technologies for the on-demand fabrication of complex polymer-based objects, efforts have been underway to adapt 3-D printing technologies and engineer bioprinting instruments that can leverage similar 3-D replication concepts and accommodate the incorporation of living cells.

First-generation 3-D prototyping techniques relied on subtractive processes—the removal of material from a solid block using filing, milling, drilling, cutting and grinding methods. Advanced 3-D prototyping technologies utilize additive processes in which the desired part is built up—or “printed” layer-by-layer. Objects of virtually any shape can now be fabricated from a wide range of non-biological materials using additive technologies.

The power and utility of 3-D printing in the non-biological materials area has sparked the imaginations of biologists and engineers alike and fueled R&D activities aimed at producing intricate biological 3-D structures. Consequently, precise, automated, layer-by-layer fabrication of tissue (bioprinting) is now possible using only living cells as building blocks. This is resulting in simultaneous achievement of unique features such as true 3-D, tissue-like cellular densities and reproduction of native tissue architecture through the spatially directed placement of distinct cell types.

Bioprinting hardware requires unique features that ensure success at the interface of engineering and biology.

The Latest Bing News on:

Bioprinting

- 3D bioprinting for functional tissue fabricationon April 18, 2024 at 5:00 pm

Accept & Close The ACS takes your privacy seriously as it relates to cookies. We use cookies to remember users, better understand ways to serve them, improve our value proposition, and optimize their ...

- 3D printing and bioprinting in healthcare - statistics and factson April 10, 2024 at 5:00 pm

Bioprinting is a much newer technology compared to 3D printing and uses bioinks and other biomaterials to create organ-like structures. Some have referred to bioprinting as ‘healthcare’s next ...

- Advancing gastric cancer treatment through personalized 3D bioprintingon March 21, 2024 at 10:37 am

By using 3D bioprinting to accurately replicate the biological environment surrounding gastric cancer cells, the researchers have achieved a significant feat—predicting a patient's response to ...

- 3D printing and bioprinting in healthcareon March 19, 2024 at 11:46 am

3D bioprinting is a much newer technology and uses bioinks mixed with living cells to print structures to be used in the human body. A chapter on this technology is also included in this report.

- Bioprinting News and Researchon March 17, 2024 at 5:00 pm

FluidForm Bio, a leader in developing life-like human tissue to treat disease, shares recent advancements in building human cardiac tissues using FRESH™ 3D bioprinting. FluidForm Bio ...

- Students create 3D-bioprinting system to replicate chemicals in plantson February 7, 2024 at 1:34 am

Meet "Team RoSynth," a group of ten students who, with their cutting-edge 3D-bioprinting system, are revolutionizing the production of plant-based pharmaceuticals without relying on actual plants.

- TissueFab® bioink Conductive for 3D bioprintingon November 22, 2023 at 11:00 pm

TissueFab ® bioink Conductive Vis/405 nm, low endotoxin, is a bioink tailored for 3D bioprinting with electrical conductivity. This specialized bioink is designed to create optimal conditions for ...

- Revolutionising osteoarthritis treatment through bioprintingon September 25, 2023 at 7:40 am

In collaboration with clinicians and cell biologists and using the unique capability of The University of Manchester’s Bioprinting Platform, Dr Marco Domingos is developing new technology-driven ...

- 26 Million New Cases, Three Dimensions, And One New Technology: How Bioprinting Can Improve Cancer Treatmentson July 11, 2023 at 3:30 pm

printed from a model (such as the gold bracelet model seen on the laptop screen). Bioprinting, also known as 3D bioprinting, uses cells, growth factors (naturally occurring substances that help ...

The Latest Google Headlines on:

Bioprinting

[google_news title=”” keyword=”Bioprinting” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

The Latest Bing News on:

Tissue engineering

- AI-powered test predicts knee osteoarthritis 8 years before X-rayon April 27, 2024 at 10:33 am

A new biomarker test successfully predicted the early onset of knee osteoarthritis years ahead of noticeable signs.

- Five from Hopkins BME recognized at Young Investigators’ Dayon April 26, 2024 at 12:52 pm

Young Investigators' Day ceremony celebrates the unique contributions of junior researchers and the mentors who helped them excel in their fields.

- Parkinetics: Improved motion data collection of Parkinson’s patients in everyday lifeon April 26, 2024 at 9:11 am

A student team in the Department of Biomedical Engineering has developed a signal processing algorithm that they hope will someday help clinicians understand how well medication is working for patient ...

- Interstitium: A Network of Living Spaces Supports Anatomical Interconnectednesson April 26, 2024 at 8:29 am

What researchers once regarded as a byproduct of biology may hold the key to understanding health and disease.

- Shoulder surgeons should rethink a common practice, new study suggestson April 25, 2024 at 11:58 am

A common practice of shoulder surgeons may be impairing the success of rotator cuff surgery, a new study from orthopedic scientists and biomedical engineers at Columbia University suggests. The work ...

- National Science Foundation Awards $450-K Grant to ASU’s Engineering Programon April 25, 2024 at 10:15 am

The National Science Foundation (NSF) has just awarded Alabama State University's Dr. Vineeth Vijayan -- an assistant professor in the University's engineering department -- a grant of $450,000. He ...

- New experimental evidence unlocks a puzzle in vascular tissue engineeringon April 25, 2024 at 9:25 am

Angiogenesis is a process of forming hierarchical vascular networks in living tissues. Its complexity makes the controlled generation of blood vessels in laboratory conditions a highly challenging ...

- Lab-made miniorgans take scientists a step closer to curing canceron April 25, 2024 at 8:34 am

In the fight to cure cancer, scientists need better models. And they might just get them — human-derived organoids — thanks to light.

- Mini Colons Mimic Healthy, Tumor Tissue In Colorectal Cancer Developmenton April 25, 2024 at 12:01 am

The mini colons replicate both the physical structure and cellular diversity in the colon in both healthy and diseased states.

- Tissue Engineering and Regeneration Market [2028]: Navigating Opportunities and Challengeson April 24, 2024 at 3:11 am

USD 14.57 billion in 2022 and is poised for substantial growth, projecting a Compound Annual Growth Rate (CAGR) of 8.35% through 2028.

The Latest Google Headlines on:

Tissue engineering

[google_news title=”” keyword=”tissue engineering” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]