Biological research, sensing and diagnostics; new photonic devices that can control light waves; controllable adhesive surfaces; antireflective coatings; and antifouling surfaces . . .

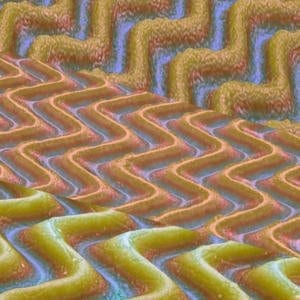

The wrinkles on a raisin result from a simple effect: As the pulp inside dries, the skin grows stiff and buckles to accommodate its shrinking size. Now, a team of researchers at MIT has discovered a way to harness that same principle in a controlled and orderly way, creating wrinkled surfaces with precise sizes and patterns.

This basic method, they say, could be harnessed for a wide variety of useful structures: microfluidic systems for biological research, sensing and diagnostics; new photonic devices that can control light waves; controllable adhesive surfaces; antireflective coatings; and antifouling surfaces that prevent microbial buildup.

A paper describing this new process, co-authored by MIT postdocs Jie Yin and Jose Luis Yagüe, former student Damien Eggenspieler SM ’10, and professors Mary Boyce and Karen Gleason, is being published in the journal Advanced Materials.

The process uses two layers of material. The bottom layer, or substrate, is a silicon-based polymer that can be stretched, like canvas mounted on a stretcher frame. Then, a second layer of polymeric material is deposited through an initiated chemical vapor deposition (iCVD) process in which the material is heated in a vacuum so that it vaporizes, and then lands on the stretched surface and bonds tightly to it. Then — and this is the key to the new process — the stretching is released first in one direction, and then in the other, rather than all at once.

When the tension is released all at once, the result is a jumbled, chaotic pattern of wrinkles, like the surface of a raisin. But the controlled, stepwise release system developed by the MIT team creates a perfectly orderly herringbone pattern.

The size and spacing of the herringbone ribs, it turns out, is determined by exactly how much the underlying material was originally stretched in each direction, the coating’s thickness, and in which order the two directions are released. The MIT team has shown the ability to control the exact size, periodic spacing and angles in both directions for the first time.

The system is unusual in its ability to produce precisely controlled patterns without the need for masks or complex printing, molding or scanning processes, Gleason says.

via Science Daily

The Latest Streaming News: Wrinkled Surfaces updated minute-by-minute

Bookmark this page and come back often

Latest NEWS

Latest VIDEO